Method for producing compressor, and compressor

A manufacturing method and compressor technology, which are applied in the field of compressor manufacturing, can solve the problems of difficulty in ensuring the positional accuracy of internal components, large-scale compressors, and large heat input, and achieve the effects of suppressing deformation and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

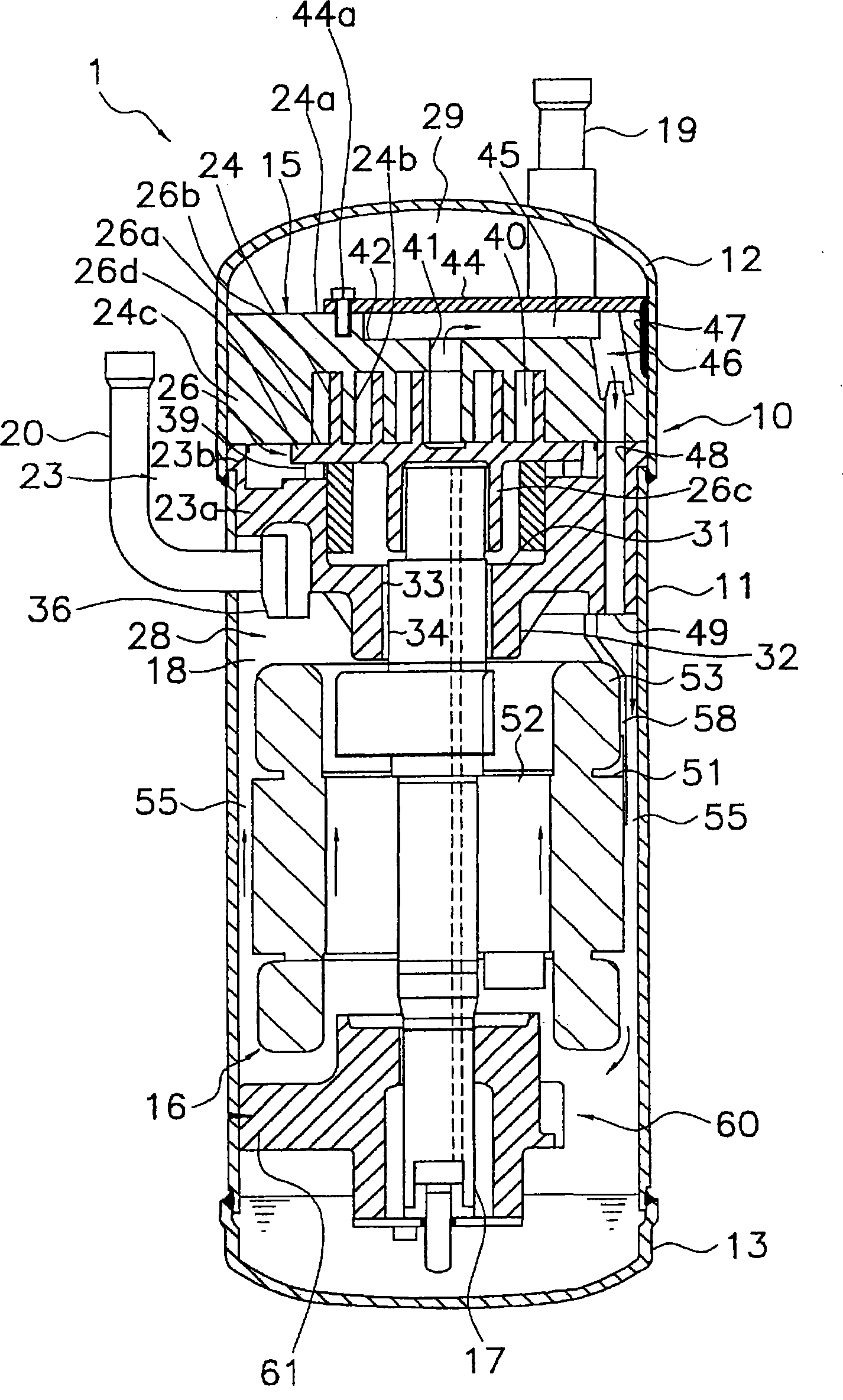

[0084] The high-low pressure dome scroll compressor 1 according to the first embodiment of the present invention constitutes a refrigerant circuit together with an evaporator, a condenser, an expansion mechanism, etc., and plays a role of compressing gas refrigerant in the refrigerant circuit, Such as figure 1 As shown, the high and low pressure dome-type scroll compressor 1 is mainly composed of a vertically long cylindrical sealed dome-shaped casing 10, a scroll compression mechanism 15, an Oldham ring (Oldham ring) 39, a driving motor 16, and a lower main bearing 60 , Suction pipe 19 and discharge pipe 20 constitute. The components of the high and low pressure dome scroll compressor 1 will be described in detail below.

[0085]

[0086] (1) Shell

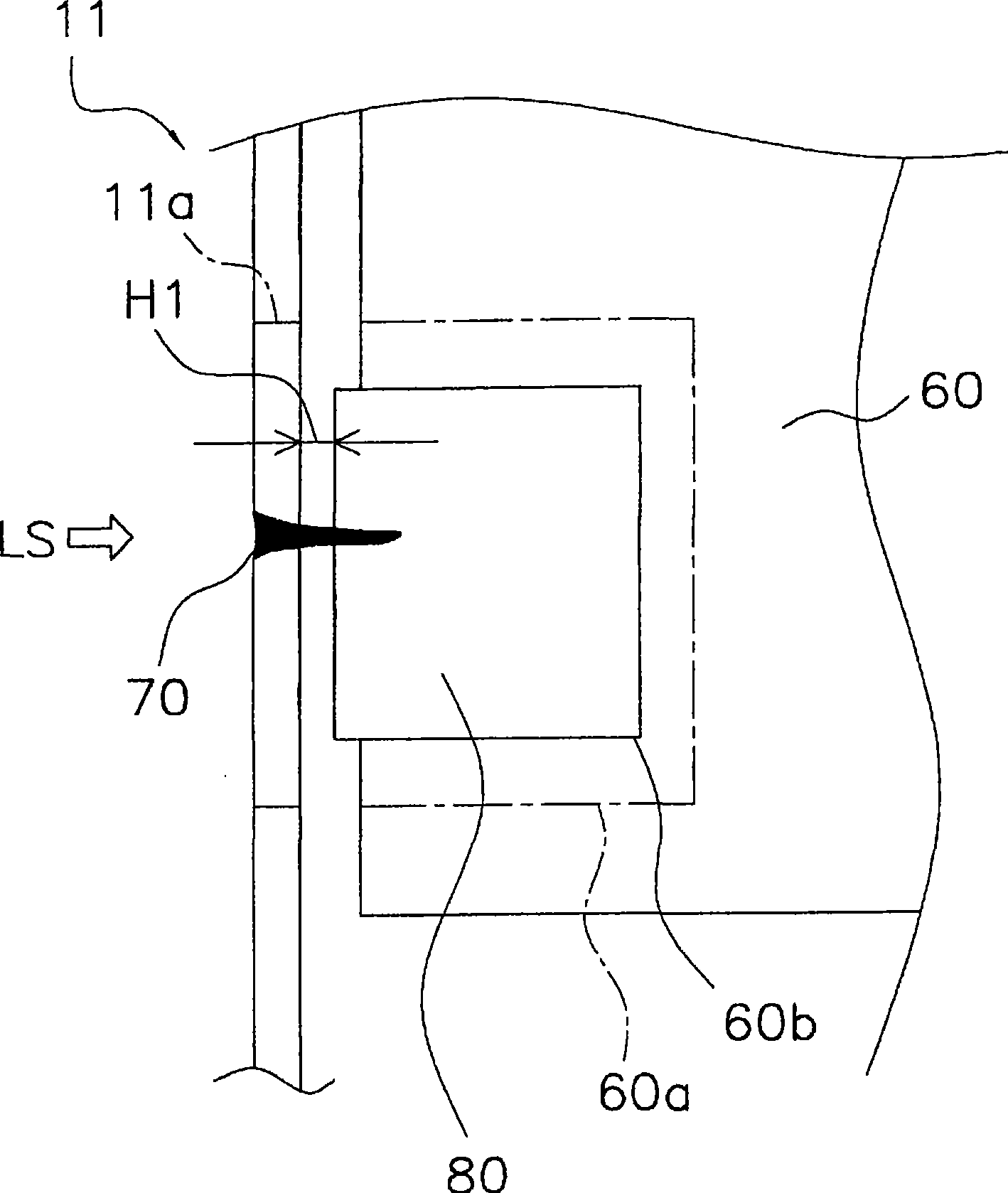

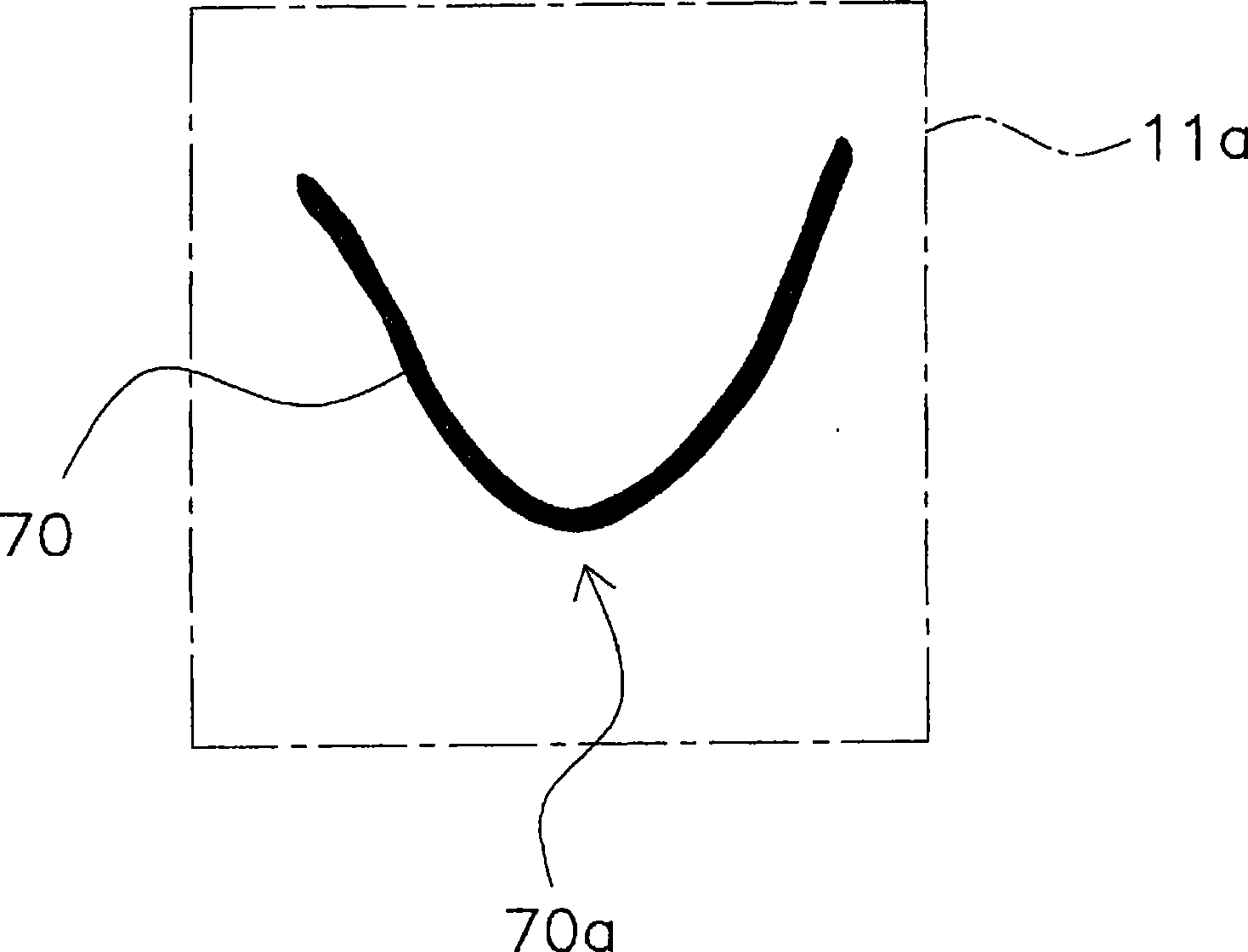

[0087] The housing 10 has: a substantially cylindrical main body housing 11; a bowl-shaped upper wall 12 welded to the upper end of the main body housing 11 in an airtight manner; Bowl-shaped bottom wall portion 13 . In add...

no. 2 Embodiment approach

[0161] The high and low pressure dome type scroll compressor according to the second embodiment of the present invention has the same structure as the high and low pressure dome type scroll compressor 1 according to the first embodiment, however, the welding method of the main body casing and the lower main bearing Wait for the difference. Therefore, the welding method of the main body shell and the lower main bearing will be mainly explained here.

[0162] In addition, the high-low pressure dome scroll compressor of the second embodiment uses CO 2 (Carbon dioxide) is designed on the premise that the gas refrigerant to be compressed requires high pressure resistance. Therefore, the plate thickness of the main body shell 11, the upper wall shell 12, and the bottom wall shell 13 is 8 to 10 mm, which is different from the usual Compressors for refrigerants such as R410A are considerably thicker than the case thickness (3 to 4 mm).

[0163]

[0164] (1) Materials

[0165] The...

no. 3 Embodiment approach

[0183]

[0184]A rotary (more specifically, a swing) compressor 101 according to a third embodiment of the present invention is as follows: Figure 7 As shown, it mainly consists of an airtight dome-shaped housing 110, a swing compression mechanism 115, a driving motor 116, suction pipes 119a, 119b and a discharge pipe 119c. In this swing compressor 101 , an accumulator (gas-liquid separator) 190 is attached to the casing 110 .

[0185] In addition, compressor 101 to use CO 2 (Carbon dioxide) is designed on the premise that it is a gas refrigerant to be compressed.

[0186] (1) Shell

[0187] The housing 110 has: a substantially cylindrical main body housing part 111; a bowl-shaped upper wall housing part 112 welded to the upper end of the main body housing part 111 in an airtight manner; The bowl-shaped bottom wall housing part 113 of the first part. Further, the housing 110 mainly accommodates: a swing compression mechanism 115 for compressing gas refrigerant; and a dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Plate thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com