Powder metallurgy preparation method of localization reinforced composite

A technology for reinforced composite materials and powder metallurgy, which is applied in the field of powder metallurgy preparation of localized reinforced composite materials, can solve the problems of reducing the performance of the matrix material, being unsuitable, and the grain growth of the matrix material, etc. Germination, uniform particle distribution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

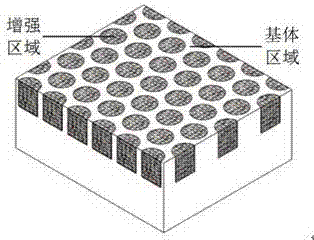

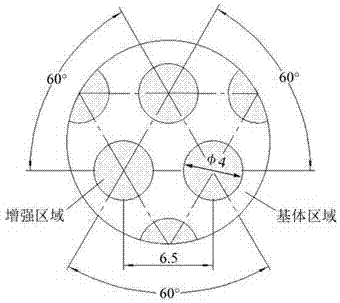

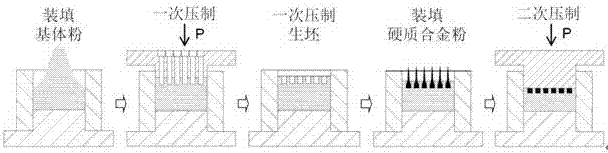

[0033] Example 1: Preparation of localized reinforced ball mill liner wear-resistant inserts

[0034] The wear-resistant medium alloy steel with good strength and toughness is selected as the matrix material, steel-bonded cemented carbide is selected for the reinforced area of the insert, WC particles are used as the reinforced particles, and reduced iron powder is used as the metal binder; the shape and shape of the reinforced area in the surface layer of the composite material distributed as figure 2 As shown, the depth of the reinforced area is 6mm, and the composite material green body molding mold is designed accordingly. The preparation of this composite material comprises the following steps:

[0035] 1) Preparation of cemented carbide powder

[0036] Mix WC particles with a particle size of 106-120 μm and reduced iron powder with a particle size of 86-106 μm. The content of WC particles accounts for 80% of the mass of the mixture.

[0037] 2) Ball mill mixing of c...

Embodiment 2

[0048] Example 2: Preparation of localized enhanced wear-resistant inserts for grinding discs of vertical roller mills

[0049] The matrix material is high manganese steel, the reinforced area of the insert is selected from steel-bonded hard alloy, the reinforced particles are WC and TiC particles, and the metal binder is high-speed steel powder; the shape and distribution of the reinforced area in the surface layer of the composite material are as follows: Figure 4 As shown, the depth of the reinforced area is 5mm, and the composite material green body molding mold is designed accordingly. The preparation of this composite material comprises the following steps:

[0050] 1) Preparation of cemented carbide powder

[0051] Take WC and TiC particles with a particle size of 58-75 μm and mix them with high-speed steel powder with a particle size of 38-58 μm. The content of WC particles accounts for 70% of the mass of the mixture; the content of TiC particles accounts for 15% ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com