Fibre reinforced intermetallic compound composite material as well as preparation and forming method thereof

A technology of intermetallic compounds and composite materials, which is applied in the field of continuous fiber-reinforced intermetallic compound composite materials and their preparation and molding. Low cost, continuous effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

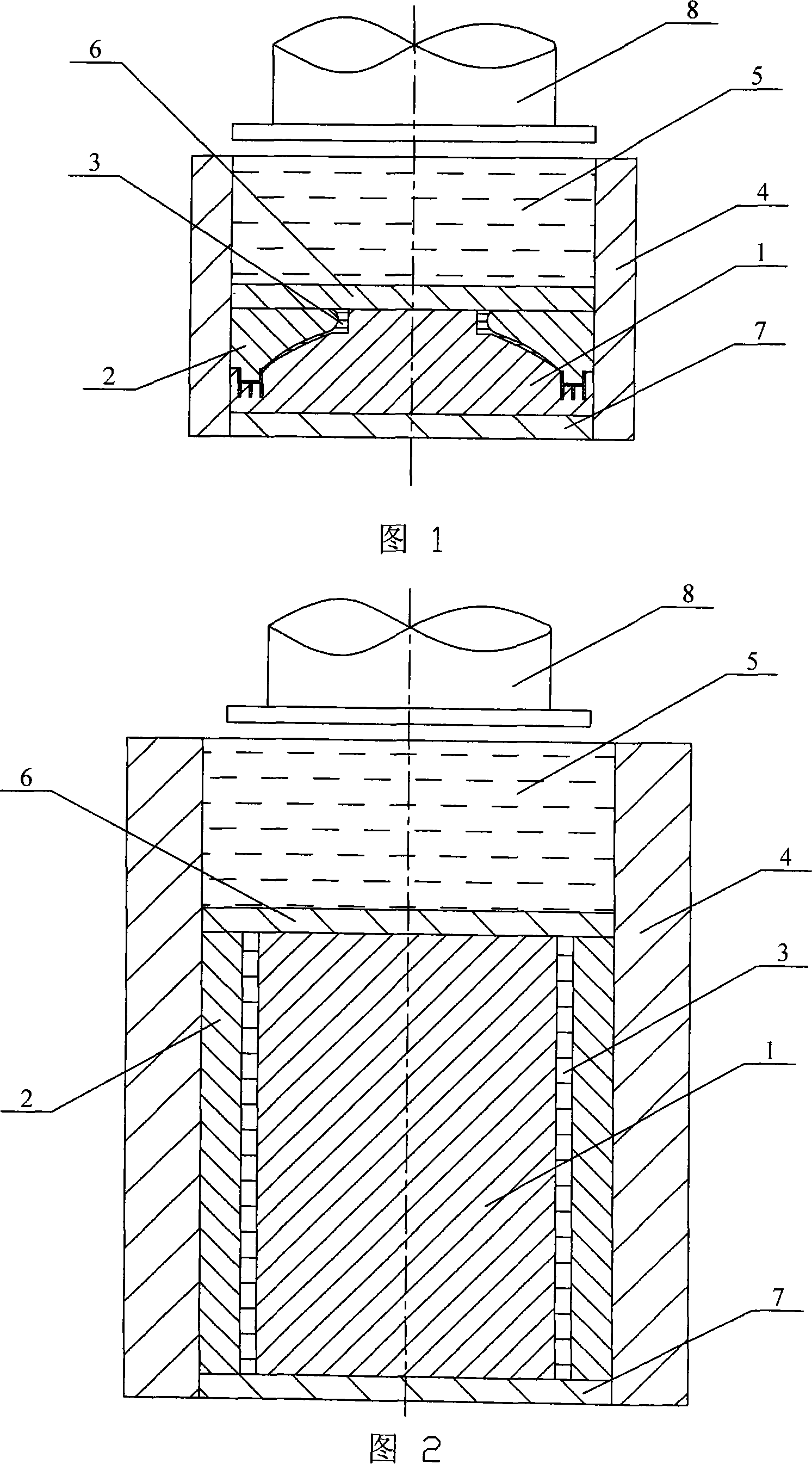

Method used

Image

Examples

specific Embodiment approach 1

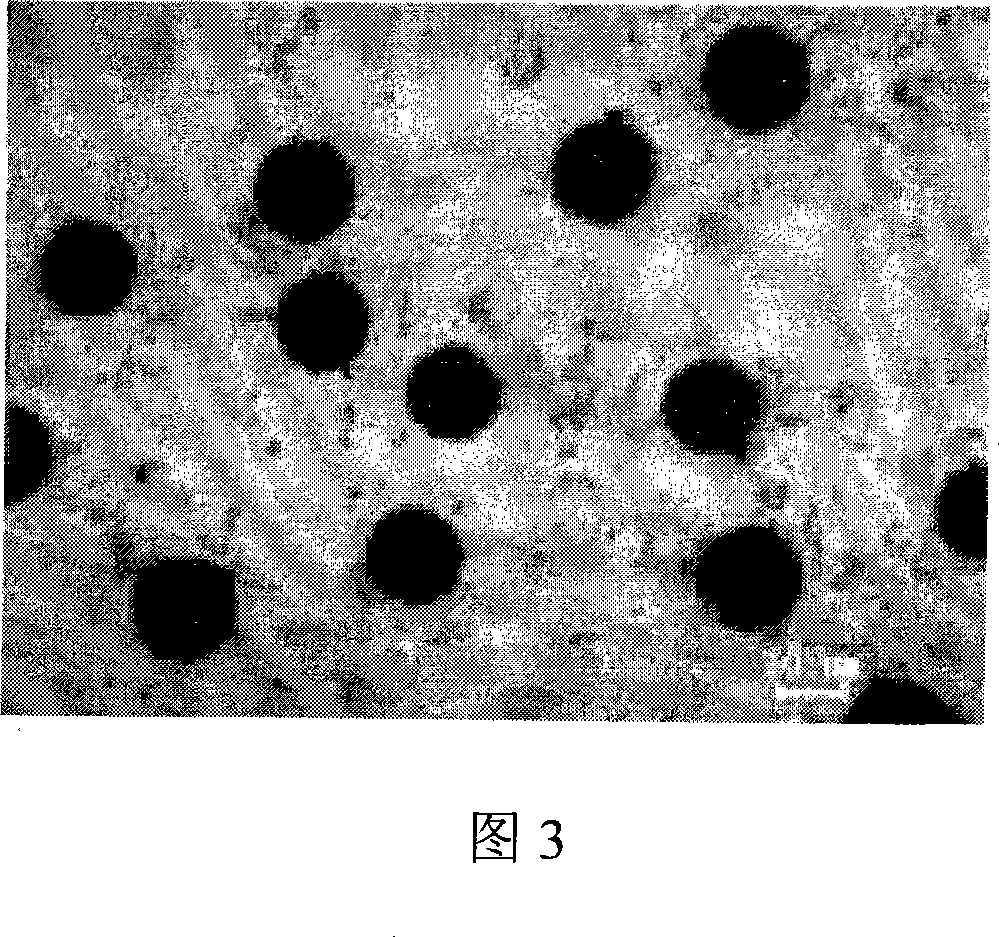

[0018] Embodiment 1: In this embodiment, the fiber-reinforced intermetallic compound composite material is composed of a titanium-aluminum intermetallic compound and a fiber reinforcement; wherein the fiber reinforcement accounts for 10% to 60% of the volume of the composite material; the titanium-aluminum intermetallic compound is Ti 3 Al, TiAl, TiAl 3 One or a mixture of several of them, it is produced by the in-situ reaction of aluminum or aluminum alloy high-temperature solution and titanium powder, the atomic ratio of titanium and aluminum is 3-1 / 3:1; the fiber reinforcement is graphite long fiber, silicon carbide long fiber, alumina long fiber, graphite short fiber, silicon carbide short fiber, alumina short fiber, graphite fiber fabric, silicon carbide fiber fabric or alumina fiber fabric.

specific Embodiment approach 2

[0019] Embodiment 2: This embodiment differs from Embodiment 1 in that the fiber reinforcement accounts for 20% of the volume of the composite material. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0020] Embodiment 3: This embodiment is different from Embodiment 1 in that the fiber reinforcement accounts for 30% of the volume of the composite material. Others are the same as in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com