Connecting structure of skirt seat and bottom sealing head

A technology of connecting structure and bottom sealing head, which is applied in gas/liquid distribution and storage, pressure vessel, fixed-capacity gas storage tank, etc. The effect of saving welding consumables and manufacturing cycle, compact structure, reducing welding and non-destructive testing work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

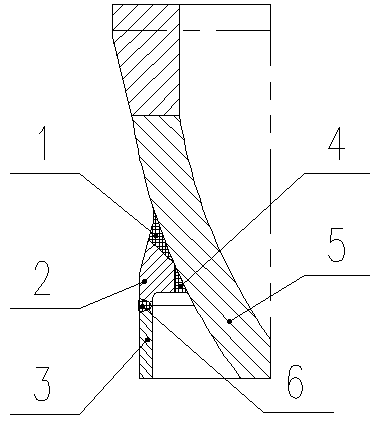

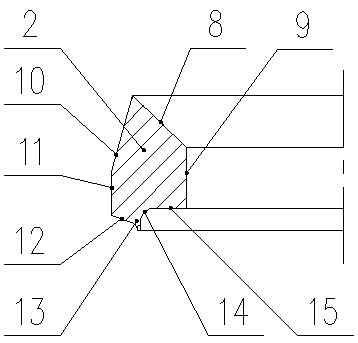

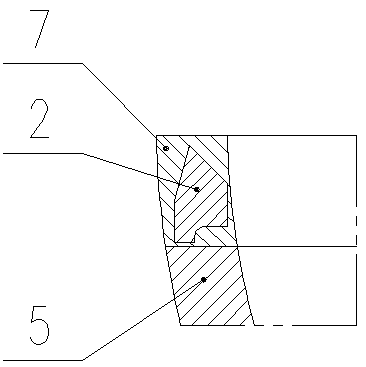

[0027] The connection structure between the skirt seat and the bottom head, the connecting member (2) is a rotary structure made of the same material as the head, and its cross-sectional shape consists of an upper bevel (8), a lower bevel (9), an outer bevel (10 ), the outer straight edge (11), the circumferential groove (12), the straight section (13), the fillet (14), and the bottom plane (15) are integrated into one, as attached figure 2 shown. It can be machined from the end stock (7) of the head, as shown in the attached image 3 shown.

Embodiment 2

[0029] According to the connection structure between the skirt seat and the bottom head described in Example 1, blunt edges can be processed at the joints of the upper bevel (8) and the lower bevel (9) as required, and the bottom of the connecting member (2) and the skirt body / The transition section (3) is provided with a straight section (13) at the junction, on which a circumferential bevel (12) is processed. There is a rounded corner (14) transition between the straight section (13) and the bottom plane (15). The outer straight edge (11) of the component (2) is consistent with the outer diameter of the skirt body / transition section (3), and the outer straight edge (11) is connected to the upper bevel (8) through the outer bevel (10), and the outer bevel ( 10) The angle with the outer straight edge (11) is generally 10-25° according to the actual shape.

Embodiment 3

[0031] First turn the head (5) upside down, put the connecting member (2) on the head (5), and then weld the lower weld (4). Since the connecting member (2) has a compact structure, there is enough space for welding and testing. Space to achieve, is conducive to ensuring the quality of welding. After the lower welding seam (4) is completed, the head (5) is turned over, and the upper welding seam (1) is welded after cleaning the root. After the welding is completed, the corresponding non-destructive testing is carried out.

[0032] After the welding of the connecting member (2) and the head (5) is completed and passed the inspection, the welding and non-destructive testing of the connecting member (2) and the skirt cylinder / transition section (3) are carried out.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com