Suction cylinder steel pipe machining and manufacturing technology for suction type jacket

A suction cylinder and jacket technology, applied in metal processing, metal processing equipment, applications, etc., can solve the problems of large fluctuations in manual welding quality, difficulty in ensuring welding quality, and difficulty in ensuring dimensional accuracy, so as to reduce offshore construction risks, The layout of the production process is reasonable and the effect of increasing the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

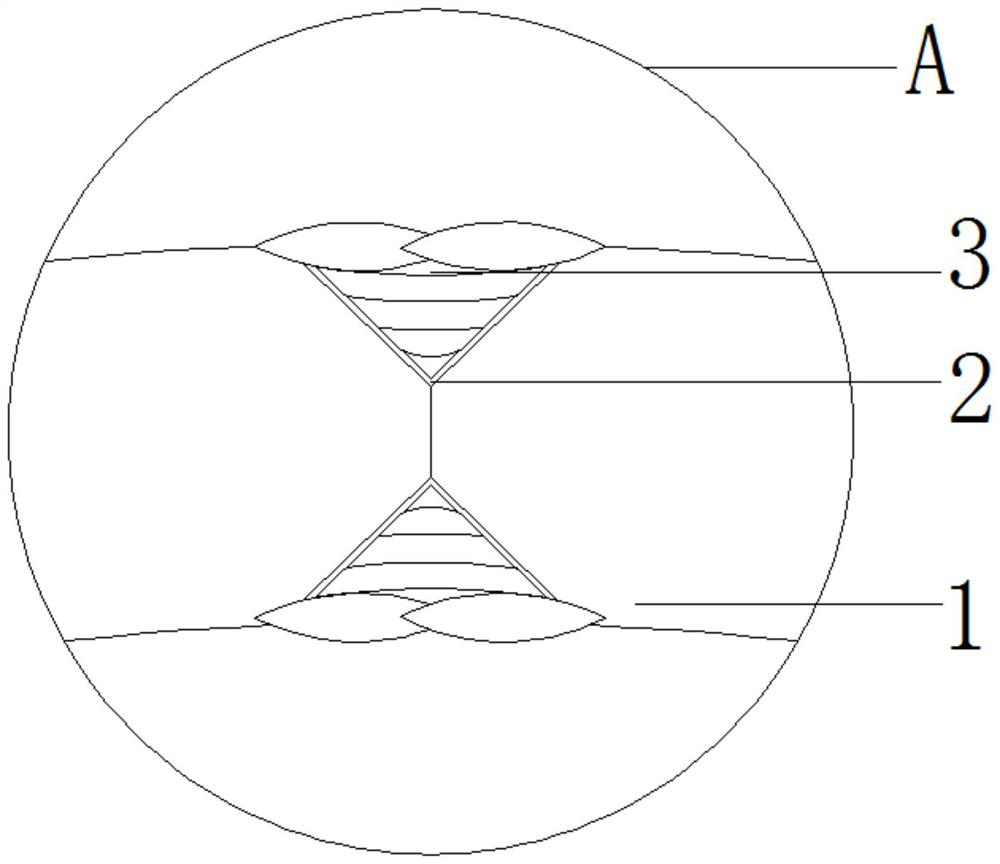

[0025] see Figure 1-2 , a suction tube steel pipe processing technology for a suction jacket, including a suction tube steel tube 1. During the processing of the suction tube steel tube, the steel plates are spliced first, and then rolled. During the rolling process, side supports and top supports are used to assist tooling to prevent The deformation of the cylinder caused by the collapse of the steel pipe due to its own weight, the longitudinal seam submerged arc welding is carried out after the rolling is completed, the two ends of the single-section steel pipe are equipped with well braces and inner reinforcement rings, and the multi-section cylinder is on the special rotating roller with side arms Carry out group pairing and transfer to the welding station with a joint axis car. When welding the circular seam, multiple positions are carried out simultaneously; the welding adopts the single-wire straight seam submerged arc welding technology, that is, the outer welding us...

Embodiment 2

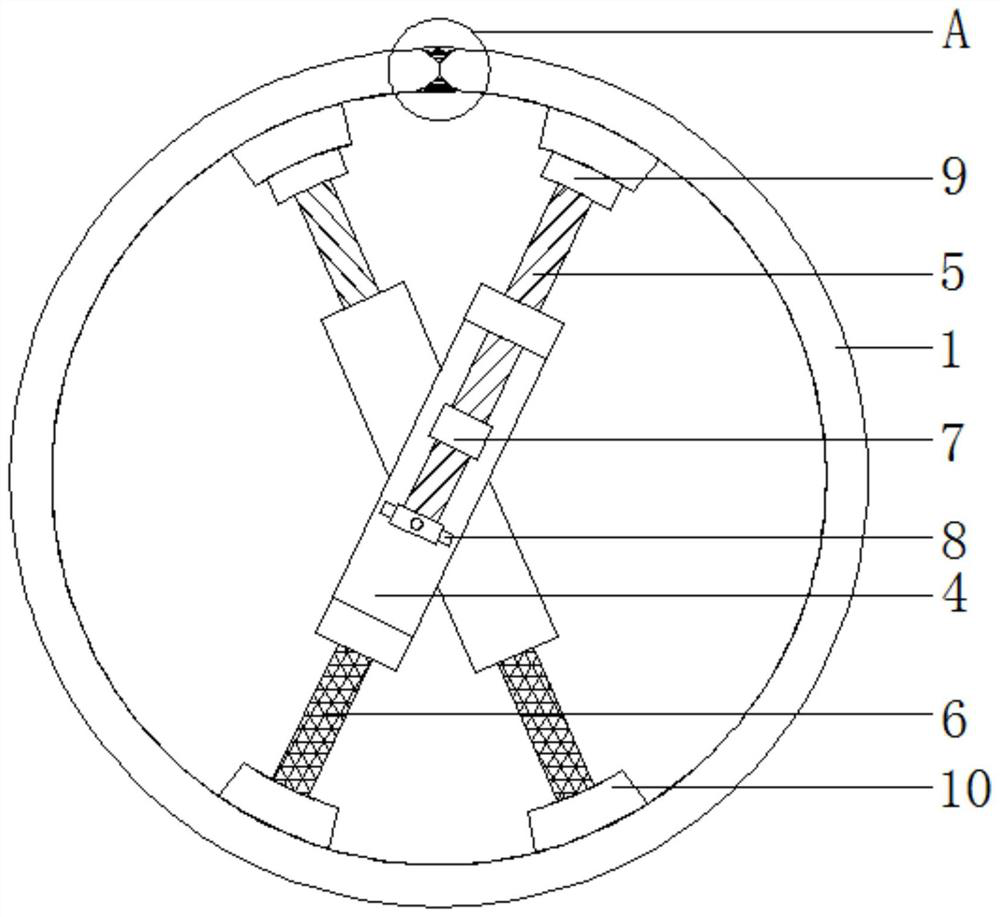

[0037] see figure 1 , the support mechanism used for the suction tube steel tube for the suction jacket includes a concave plate 4, two groups of concave plates 4 are arranged, and the back is connected by rotating shafts, and a screw rod 5 is threaded on the top of the concave plate 4, and The bottom is fixedly connected with a fixed rod 6; the bottom top of the screw rod 5 is threaded and connected with a fixed plate 7, and the bottom end is fixedly connected with a rotating handle 8, the fixed plate 7 is fixedly connected with the concave plate 4, and the upper top of the screw rod 5 is fixedly sleeved. There are bearings 9, and one side of the bearing 9 and the fixed rod 6 is fixedly connected with an arc-shaped plate 10, and the arc-shaped plate 10 is in close contact with the inner wall of the suction tube steel pipe 1; The arc-shaped plate 10 is placed on the inner wall of the suction tube steel pipe 1, and the screw 5 is rotated by adjusting the rotating handle 8. Due ...

Embodiment 3

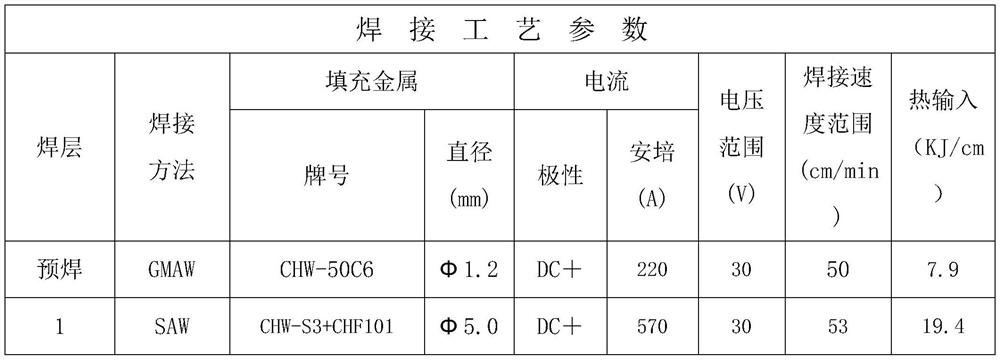

[0040] The process qualification test is carried out on the Q355ND steel plate T=30mm thick test plate, the following is the data of the assessment parameters and physical and chemical experiment analysis after welding. The welding parameters are as follows:

[0041] Table 1 Welding parameters of Q355ND suction cylinder straight seam submerged arc welded steel pipe

[0042]

[0043]

[0044] Table 2 Mechanical performance test of weld seam of Q355ND process qualification test plate

[0045]

[0046]

[0047] Cylinder force data analysis and installation of support

[0048] During the production and transshipment process, the suction cylinder steel pipe 1 has a relatively large diameter and thickness, and will collapse due to the influence of its own weight, resulting in that the roundness of the steel pipe cannot be guaranteed. Therefore, in the single-section production process, it is also necessary to install well braces and inner reinforcement rings on the end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com