Ring-shaped gas stove head and manufacturing method thereof

A ring-shaped, gas-fired technology, applied in the direction of combustion method, burner, combustion type, etc., can solve the problems of small firepower of the fire hole, uneven heating of the horn, and large firepower of the fire hole, etc. effect of fuel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

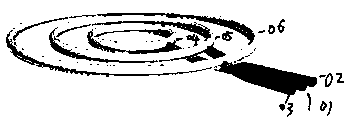

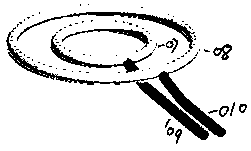

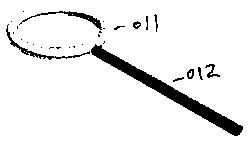

[0017] I finished the present invention like this: cut a long 190 millimeters of stainless steel pipes with a diameter of 22 millimeters with a cutting machine, cut the stainless steel pipes with a diameter of 25 millimeters, bend them into an annular stainless steel ring with an outer diameter of 200 millimeters with a pipe bender, and The edge of the outer ring of the stainless steel ring is opened with an air intake hole of the same size as the inner diameter of the intake pipe. The annular stainless steel ring and the stainless steel intake pipe are welded by argon arc welding. Use an air plasma cutting machine or a laser cutting machine to make fire holes on the stainless steel ring. The diameter of the fire holes is generally 1.5mm. The fire holes near the intake pipe are less than the fire holes far away from the intake pipe, so that the firepower is more uniform. , made into a single-ring gas stove. Cut a stainless steel round pipe with a diameter of 19 mm and a length...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com