Process for production of double-metal metallurgical composite tube through high frequency resistance welding method and composite tube

A high-frequency resistance welding and composite pipe technology, applied in resistance welding equipment, metal processing equipment, metal rolling, etc., can solve the problems of difficult quality control of lining alloys, low bonding strength, high cost, and save welding materials. and welding time, the production process is simple, and the effect of high bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical problems, technical solutions and beneficial effects solved by the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

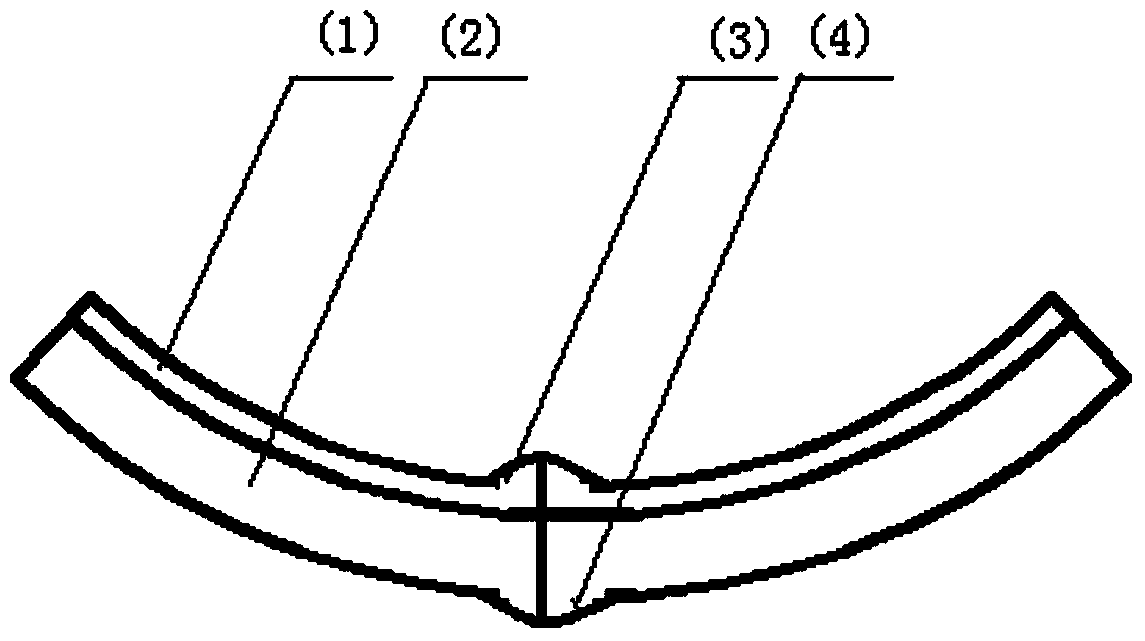

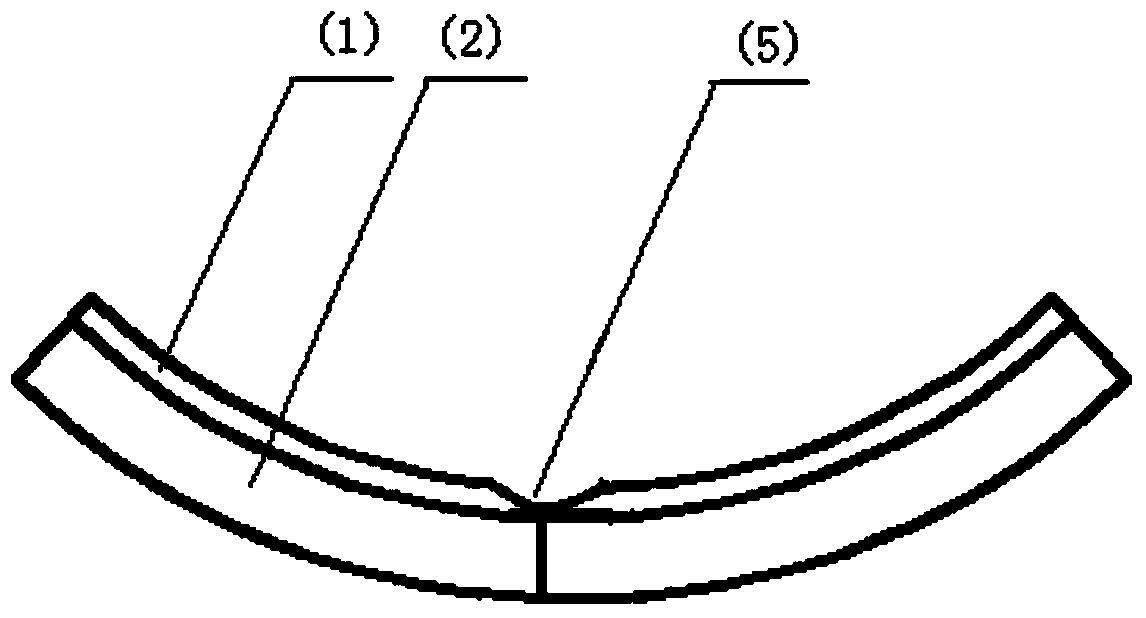

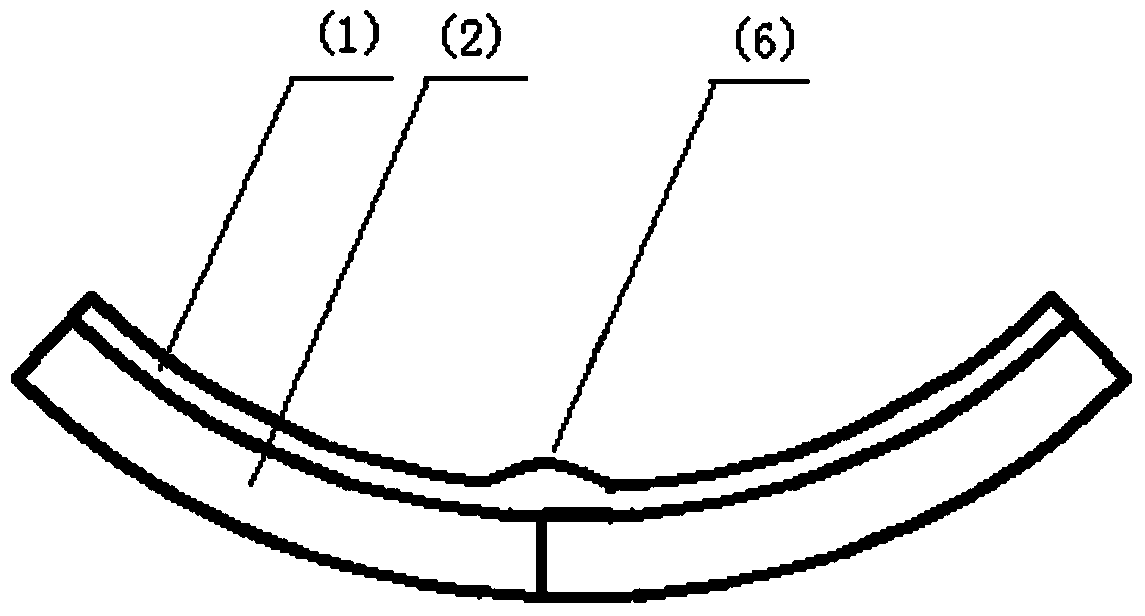

[0026] Such as Figures 1 to 3 A process for producing bimetallic metallurgical composite pipes using high-frequency resistance welding as shown includes the following steps:

[0027] In the first step, the hot-rolled metallurgical clad plate or plate coil is milled, formed and HFW welded to form a metallurgical clad steel pipe with a corrosion-resistant alloy lining inside and a base pipe outside;

[0028] The second step is to use a scraper to scrape off the outer burrs of the base pipe, so that the weld seam formed after the HFW welding is flush with the adjacent bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com