Automobile muffler

A technology of automobile muffler and capacity expansion chamber, which is applied to muffler devices, machines/engines, engine components, etc., can solve the problems of safety threats to the car body and the passengers, the muffler package bursts open, the package body heats up and turns red, etc. The effect of reducing airflow velocity, reducing automobile exhaust noise and secondary noise, and avoiding secondary noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

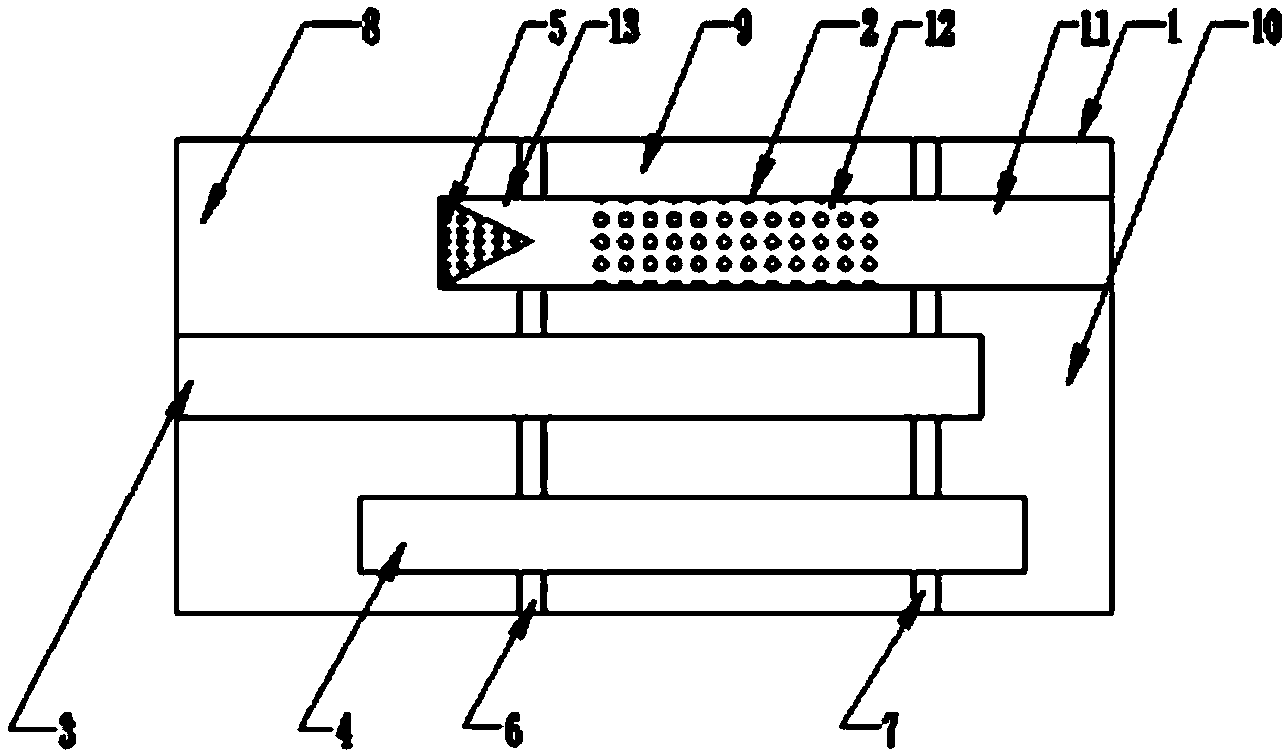

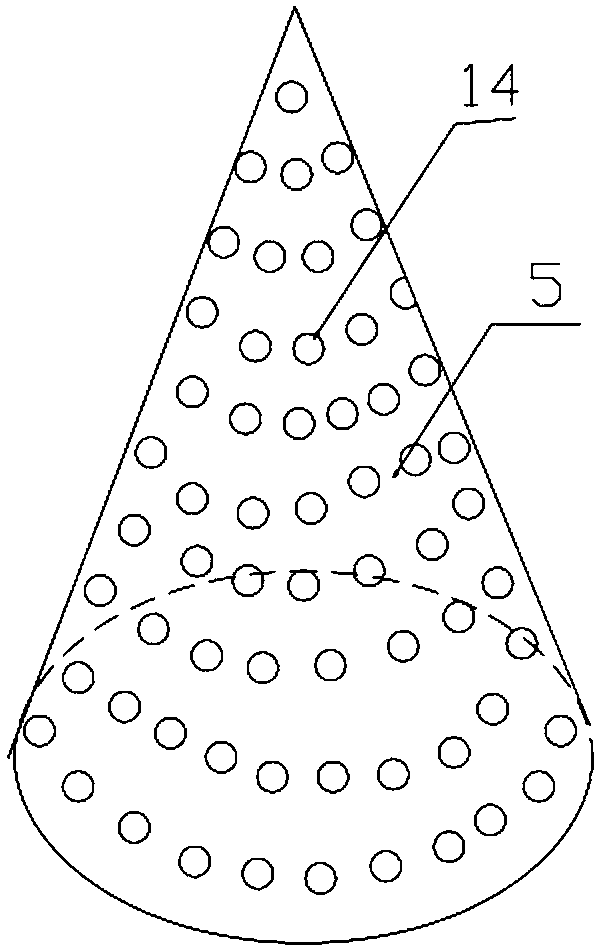

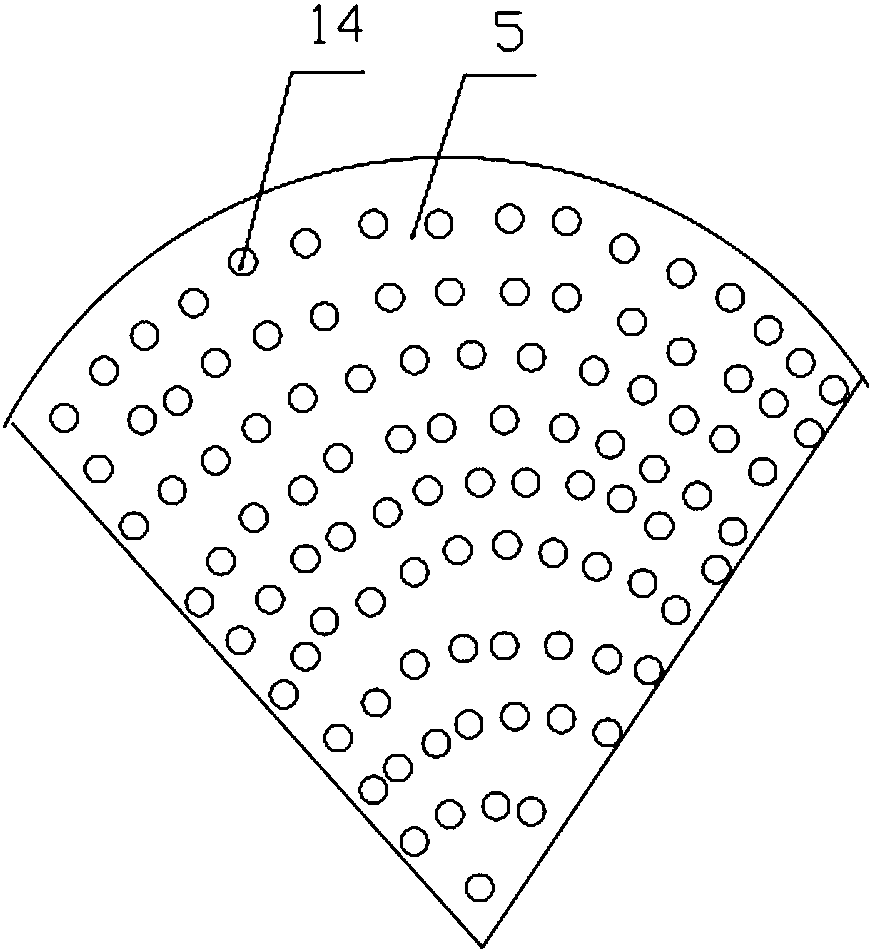

[0028] Such as figure 1 Shown, a kind of automobile muffler comprises package body 1, intake pipe 2 arranged in said package body 1, exhaust pipe 3, air return pipe 4, cone 5, first partition 6 and second partition 7 , characterized by:

[0029] The first partition 6 and the second partition 7 are arranged in parallel to divide the enclosure 1 into three relatively closed cavities, namely the first expansion cavity 8, the resonant cavity 9 and the second expansion cavity 10. The air inlet pipe 2, the exhaust pipe 3 and the air return pipe 4 are parallel to each other and arranged vertically with the first and second partitions in the enclosure 1; the relative sealing here refers to the space between each cavity. I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com