Column plate longitudinal seam abutting method

A technology of longitudinal seams and trays, which is applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of horse feet needing to be polished, unable to meet production requirements, time-consuming, etc., to improve the appearance quality, Reduce labor intensity, effect of surface quality assurance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

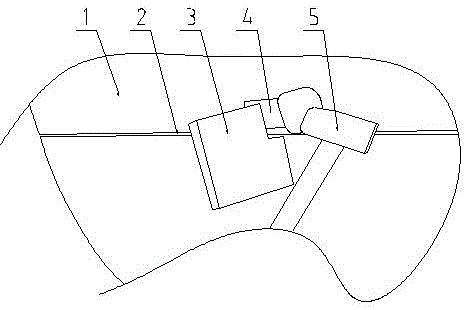

[0026] A method for butt jointing of vertical seams of trays in this embodiment, said method comprising the following steps:

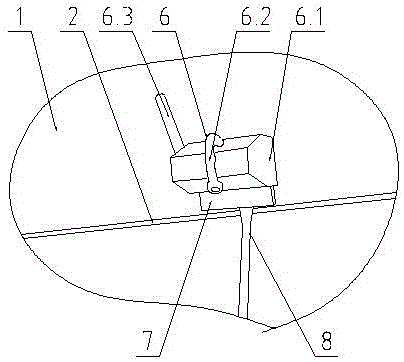

[0027] Take a positioning tool, see figure 2 , the tooling includes a permanent magnet lifter 6, the front side of the permanent magnet lifter 6 is provided with a strip plate 7, and the strip plate 7 is higher than the bottom surface of the permanent magnet lifter 6;

[0028] The permanent magnet lifter 6 is fixedly adsorbed on one side of the vertical slit of the tower plate, so that the strip plate 7 is flush with the vertical slit of the tower plate. Since the strip plate 7 is higher than the bottom surface of the permanent magnet lifter 6, the strip plate 7 and the There is a certain gap between the trays;

[0029] Take a crowbar and insert it into the gap between the strip plate 7 and the column plate, use the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com