Method for drawing costal scute in shipbuilding

A rib plate and ship technology, applied in ship construction, ship parts, ships, etc., can solve the problems of inefficiency, inability to adapt to ship construction progress requirements, waste of repair boards, etc., to save steel, eliminate repair boards, and improve construction quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The method for pulling in ribs in shipbuilding of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention cannot be limited by this. During the construction of a 297,000 DWT VLCC large oil tanker, we adopted the method of drawing ribs of the present invention.

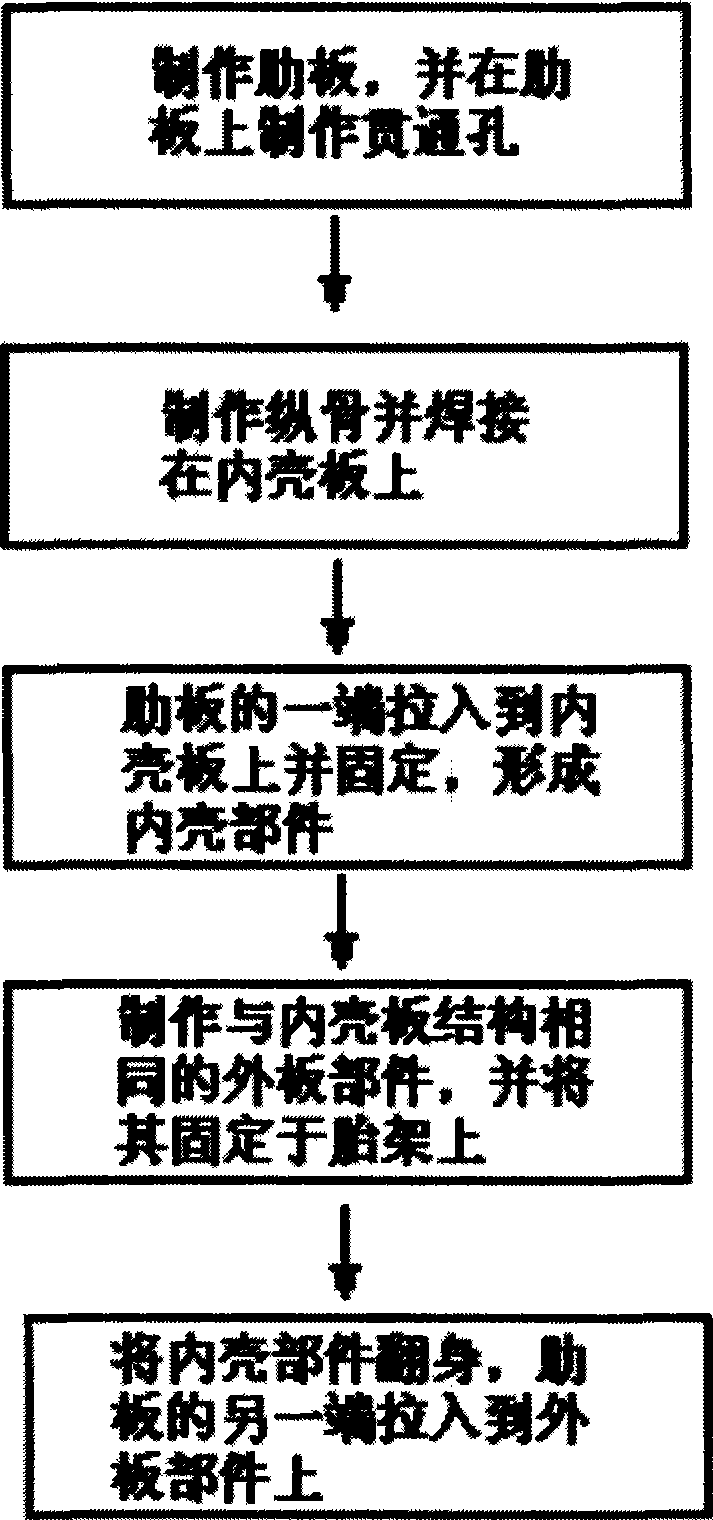

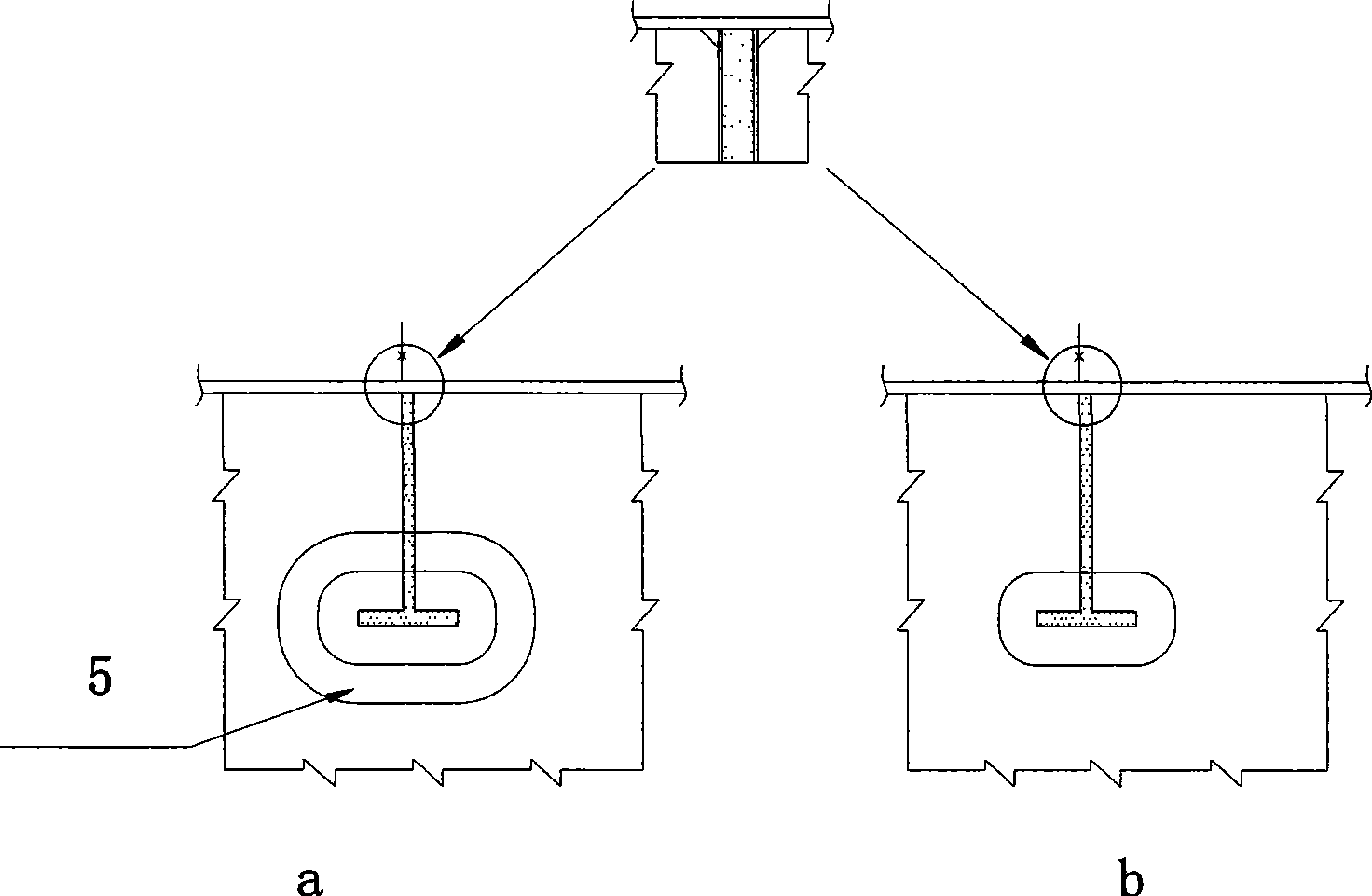

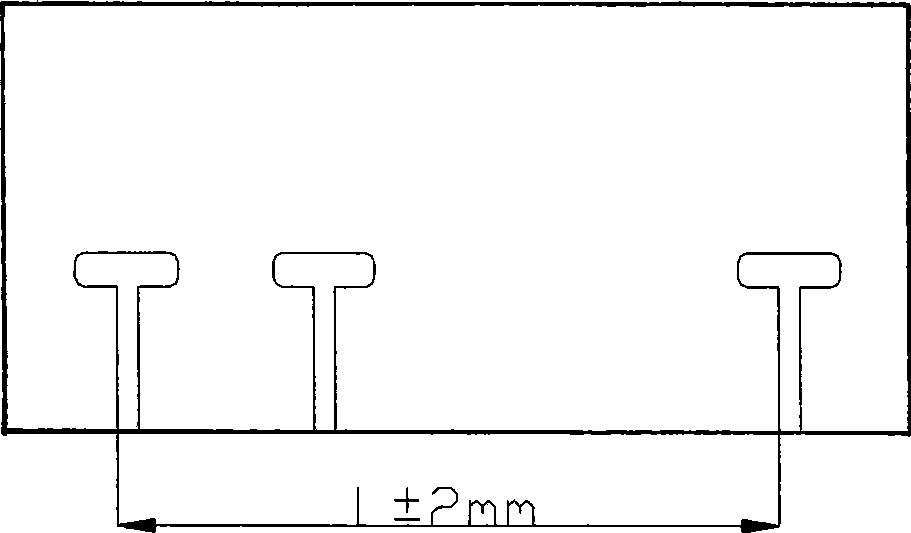

[0055] Similar to the drawing-in method of single-sided floor in the prior art, the drawing-in method of floor in shipbuilding of the present invention generally includes blanking and fabrication of longitudinals; checking installation of longitudinals; checking longitudinals Installation accuracy; check the cutting accuracy of the rib plate; install the lower channel steel of the rib plate; penetrate the rib plate into the longitudinal frame; determine the welding process for welding. On the basis of the above, the method of the present invention is as figure 1 as shown, figure 1 I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com