Self-protection flux-cored wire for steel rail repair welding

A flux-cored welding wire and rail welding repair technology, which is applied to rails, welding/welding/cutting items, rails, etc., can solve the problems of difficult to guarantee the quality stability of rail welding repairs and low efficiency, and reduce the cost and efficiency of line maintenance High, high-quality welded joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

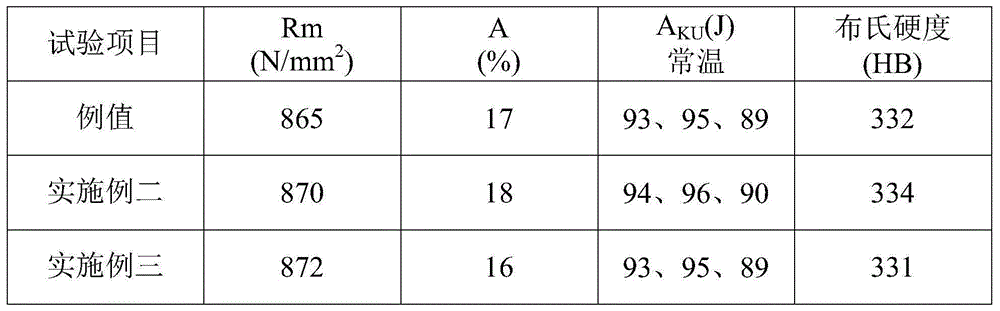

Examples

Embodiment 1

[0018] A self-shielding flux-cored wire for rail welding repair, the flux core includes alloy components and slag-based components, and the alloy components include the following components in parts by weight: 0.11 parts of C, 0.75 parts of Cr, and 2.10 parts of Ni , Mo0.45 part, Zr0.01 part;

[0019] The slag-based components include the following components in parts by weight, Fe 2 o 3 9.5 parts, BaCO 3 1.3 parts, aluminum-magnesium alloy 13.5 parts, BaF 2 25.5 parts, CaF 2 8.5 parts, LiF 2 14.5 parts, rare earth ferrosilicon 10.5 parts, Al 2 o 3 5.5 servings.

[0020] Its outer skin is a steel strip with a thickness of 0.6mm.

Embodiment 2

[0022] A self-shielding flux-cored wire for rail welding repair, the flux core includes alloy components and slag-based components, and the alloy components include the following components in parts by weight: 0.13 parts of C, 0.90 parts of Cr, and 2.30 parts of Ni , Mo0.50 part, Zr0.025 part;

[0023] The slag-based components include the following components in parts by weight, Fe 2 o 3 10 parts, BaCO 3 2 parts, aluminum-magnesium alloy 14.5 parts, BaF 2 30 parts, CaF 2 10 parts, LiF 2 15.5 parts, rare earth ferrosilicon 12 parts, Al 2 o 3 6.5 servings.

[0024] Its outer skin is a steel strip with a thickness of 0.6mm.

Embodiment 3

[0026] A self-shielding flux-cored wire for rail welding repair, the flux core includes alloy components and slag-based components, and the alloy components include the following components in parts by weight: 0.14 parts of C, 1.00 parts of Cr, and 2.40 parts of Ni , Mo0.55 part, Zr0.03 part;

[0027] The slag-based components include the following components in parts by weight, Fe 2 o 3 10.5 parts, BaCO 3 2.5 parts, 15 parts of aluminum-magnesium alloy, BaF 2 38 parts, CaF 2 11 parts, LiF 2 16 parts, rare earth ferrosilicon 13 parts, Al 2 o 3 7 servings.

[0028] Its outer skin is a steel strip with a thickness of 0.6mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com