Turn over bracket for flat plate

A technology of platform boards and brackets, which is applied in auxiliary devices, ship construction, ships, etc., can solve the problems of waste of auxiliary materials, achieve convenient maintenance, high work efficiency, and solve the effects of insufficient tooling parts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

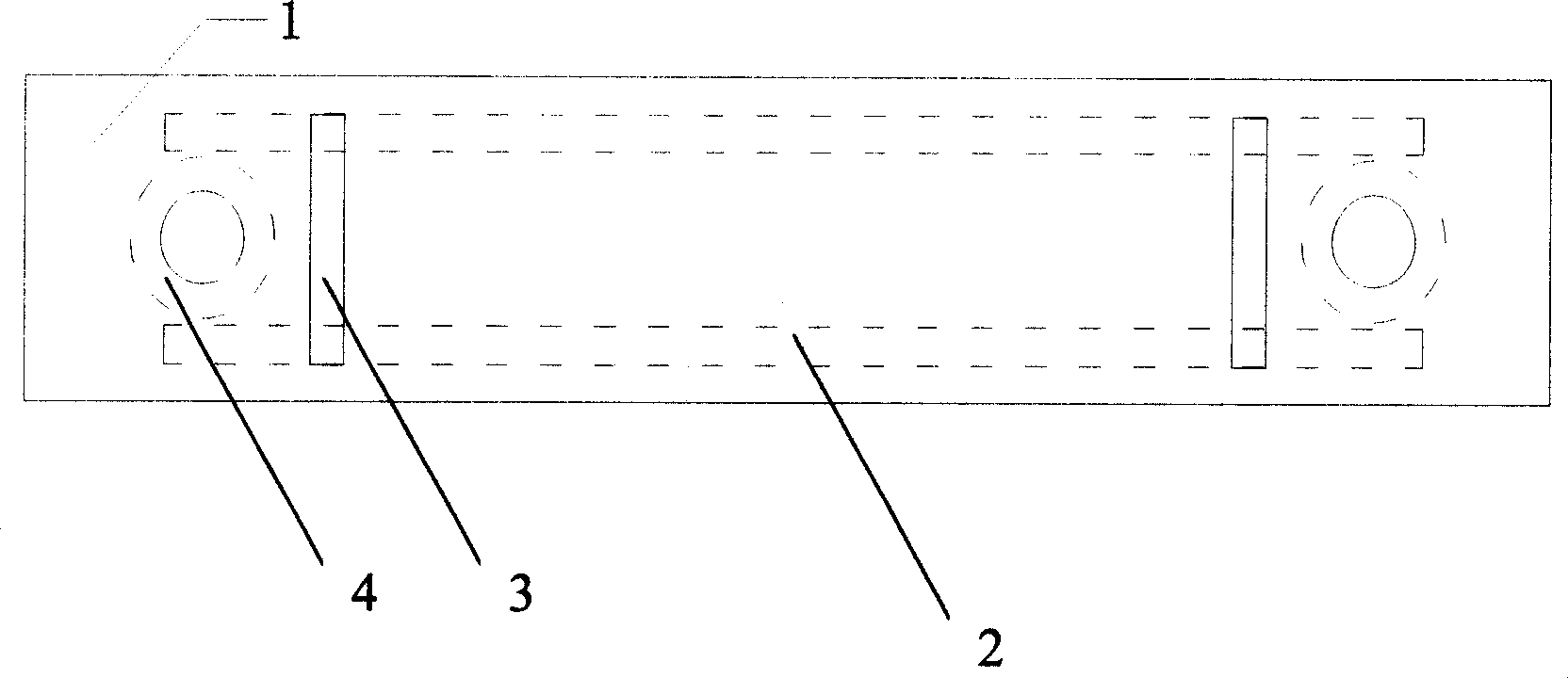

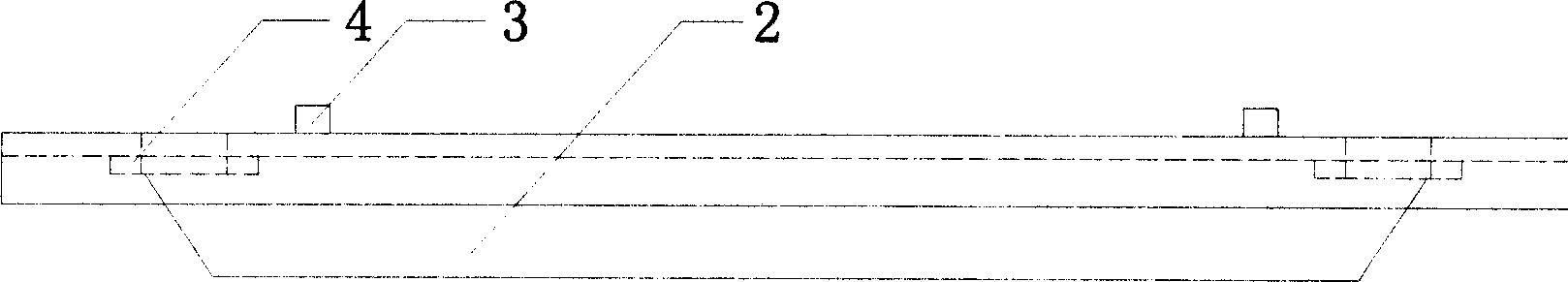

[0011] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments. like figure 1 and figure 2 As shown, the present invention includes channel steel 1 , two reinforcing ribs 2 , two square steels 3 , and two reinforcing rings 4 .

[0012] The flat surface of the channel steel 1 is taken as positive, and the chamfered surface is negative for description. On the center line of the channel steel 1, two points with a distance of 1 meter are taken as the center of the circle, and two elliptical holes with a long axis of 70 mm and a short axis of 60 mm are respectively opened. When the bracket of the present invention is used, the bracket passes through the The oval hole is sleeved on the tire frame. Since the strength of the channel steel 1 may not be enough to support the platform plate, two reinforcing ribs 2 are installed in the opposite corners to strengthen the rigidity of the channel steel 1, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com