Method for controlling welding deformation between seal head and skirt transition section

A technology of welding deformation and transition section, which is applied in welding equipment, welding equipment, auxiliary welding equipment, etc., and can solve problems such as out-of-tolerance of circular seam misalignment, welding deformation of the opening end of the head, affecting the ellipticity of the opening end of the head, etc. , to achieve the effect of reducing working hours, controlling welding deformation and saving welding consumables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the present invention more comprehensible, a preferred embodiment is described in detail below with accompanying drawings.

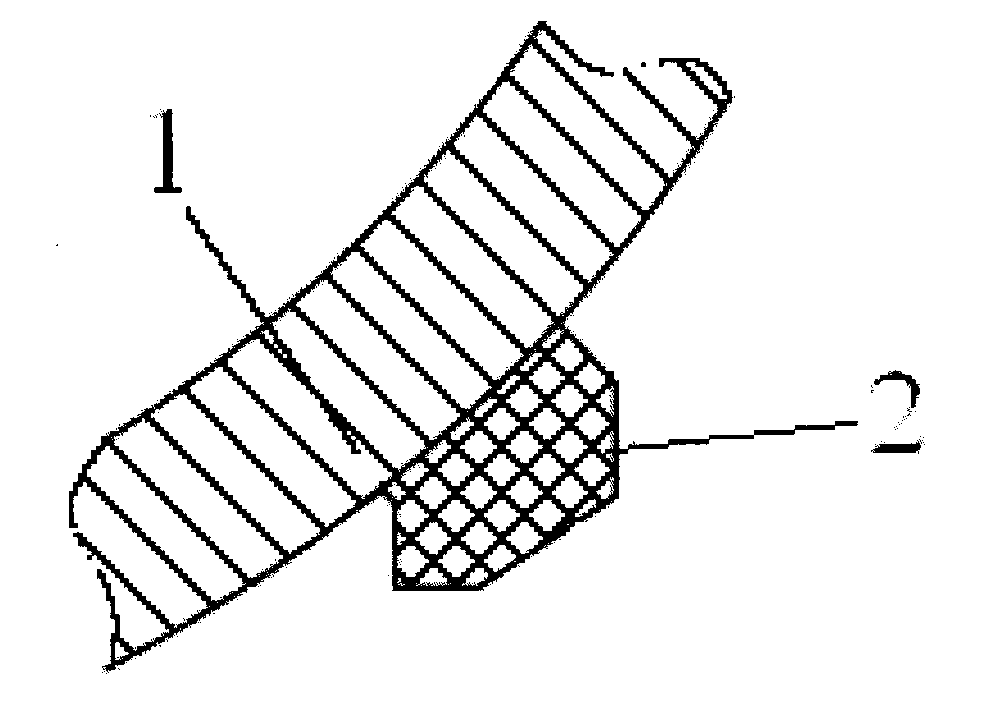

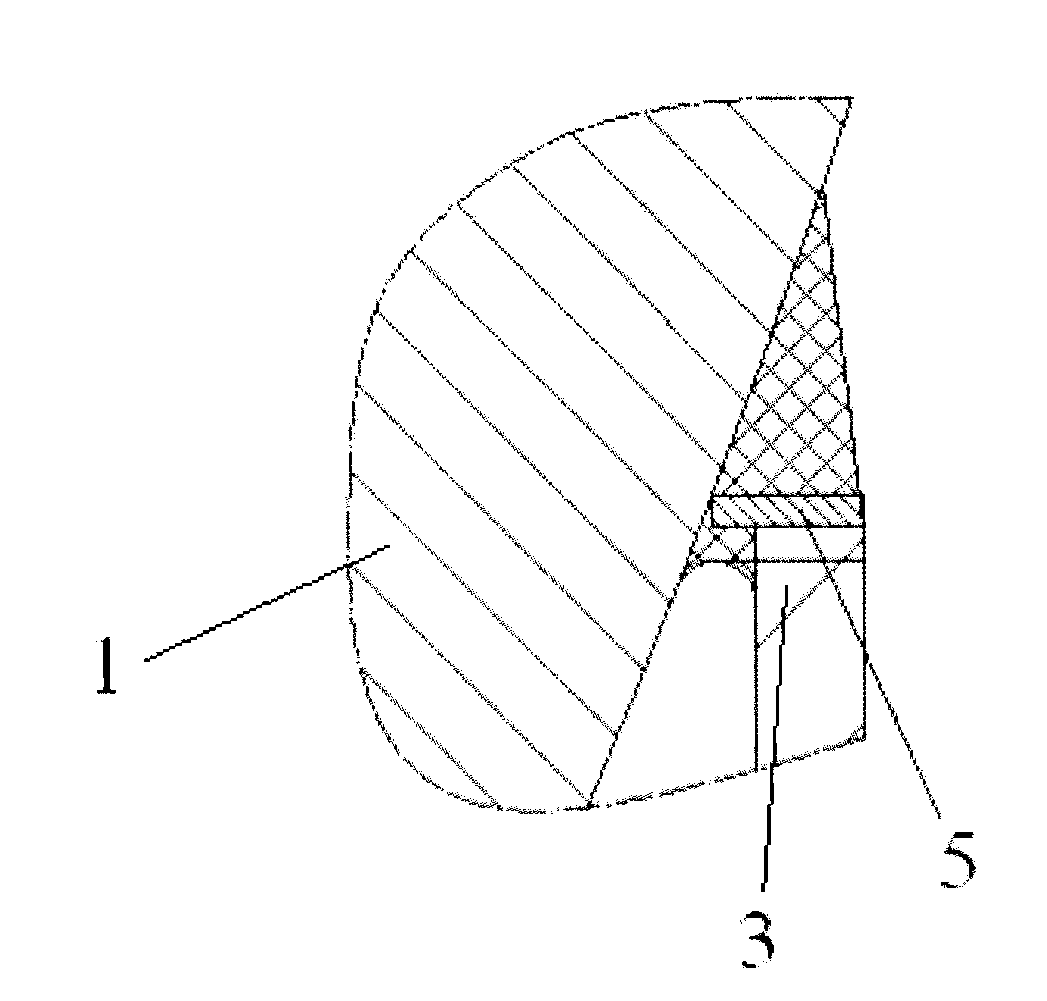

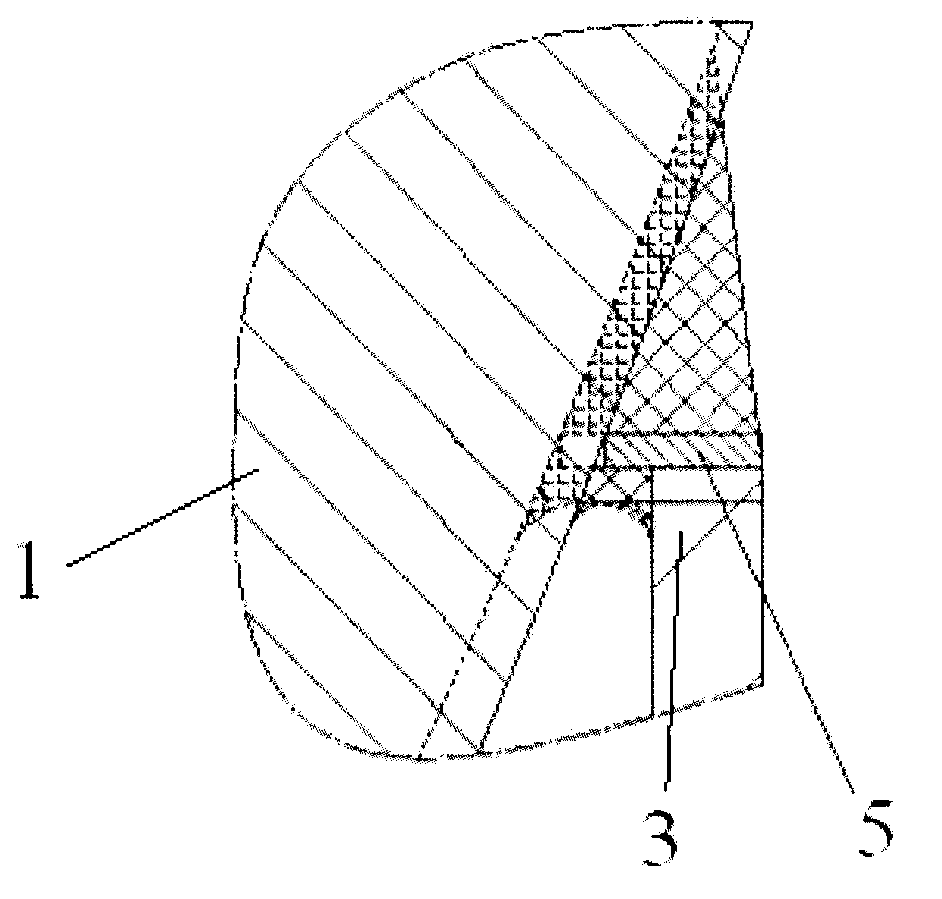

[0026] figure 2 A schematic diagram of the structure obtained by using a method for controlling the welding deformation between the head and the skirt transition section provided by the present invention, the described method for controlling the welding deformation between the head and the skirt transition section consists of the following 5 steps composition:

[0027] Step 1: Install a welding process backing plate 5 above the transition section of the outer wall of the head 1 designed to assemble the skirt;

[0028] Step 2: Weld the skirt transition section 3 on the bottom of the process backing plate 5, and perform surfacing welding between the inner side of the skirt transition section 3 and the head 1;

[0029] Step 3: remove the process backing plate 5;

[0030] Step 4: Weld the ring seam between the head 1 and the cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com