Intelligent and efficient welding method of thin-wall stainless steel

A welding method and stainless steel technology, applied in welding equipment, plasma welding equipment, arc welding equipment, etc., can solve the problems of small heat input, low efficiency, low thermal conductivity, etc., to improve welding speed, improve labor environment, The effect of improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

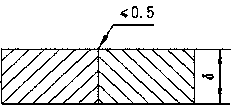

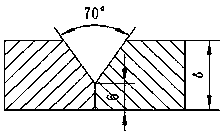

[0013] Case: The base material is S30408 stainless steel with a thickness of 10mm, and the groove is as figure 2 As shown, the welding wire adopts ER308L, the specification φ1.0, the chemical composition and mechanical properties of the base metal and welding wire are shown in Table 1; the high-efficiency intelligent welding method of stainless steel is adopted, that is, the plasma arc welding and argon tungsten arc welding are passed through during the welding process. The automatic control system is mechanically combined for welding, and the process parameters are shown in Table 2.

[0014] Table 1 Chemical composition and mechanical properties of base metal and welding consumables

[0015]

[0016] Table 2 Welding process parameters

[0017]

[0018] Argon was used as the shielding gas, and the two test pieces were welded with the standard parameters shown in Table 2. image 3 , Figure 4 As shown, the front and back of the weld seam are formed beautifully and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com