Pull-in manufacturing method of rib plates of ship shell plate

A manufacturing method and rib technology, which are applied in ship construction, hull design, ship parts, etc., can solve the problems of time-consuming and laborious assembly, poor assembly, poor welding accuracy, and low efficiency, so as to reduce labor and labor intensity and improve construction efficiency. and quality, the effect of saving steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

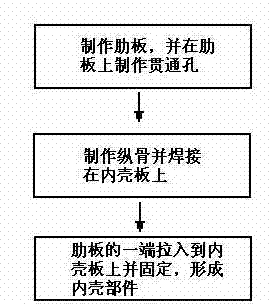

[0023] figure 1 As shown, a kind of ship shell rib pull-in manufacturing method comprises the following steps:

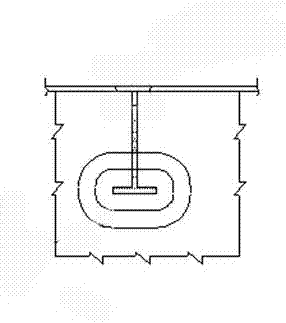

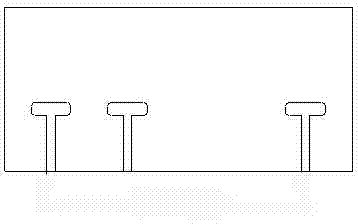

[0024] a. Cut the ribs according to the precision requirements of the ship: the allowable deviation of the outer dimensions of the ribs: for a rib with a length of 10m, the length deviation is not greater than ±2mm, and the height deviation is not greater than ±1mm; the upper and lower ends of the ribs are equipped with multiple A through hole along its length direction, the cutting accuracy tolerance of the two through holes is ±3mm; the cutting accuracy deviation d of the upper and lower sides of the cross-section of the rib is not greater than ±1.0mm (such as figure 2 , 3 , 4 shown);

[0025] b. According to the precision requirements of the ship, the longitudinal face plate and longitudinal web are cut, and then assembled to make the longitudinal: every 2m of longitudinal face plate and longitudinal web, the unevenness is ±1.0mm, the straightness is ±1.0mm ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com