Sandy soil screening device for road and bridge construction

A technology for bridge construction and screening device, which is applied to roads, bridges, roads, etc., can solve the problems of affecting screening efficiency, sand and gravel residues, and difficulty in cleaning sand and soil swing conveying screens, so as to increase screening efficiency and prevent sand and gravel. residual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

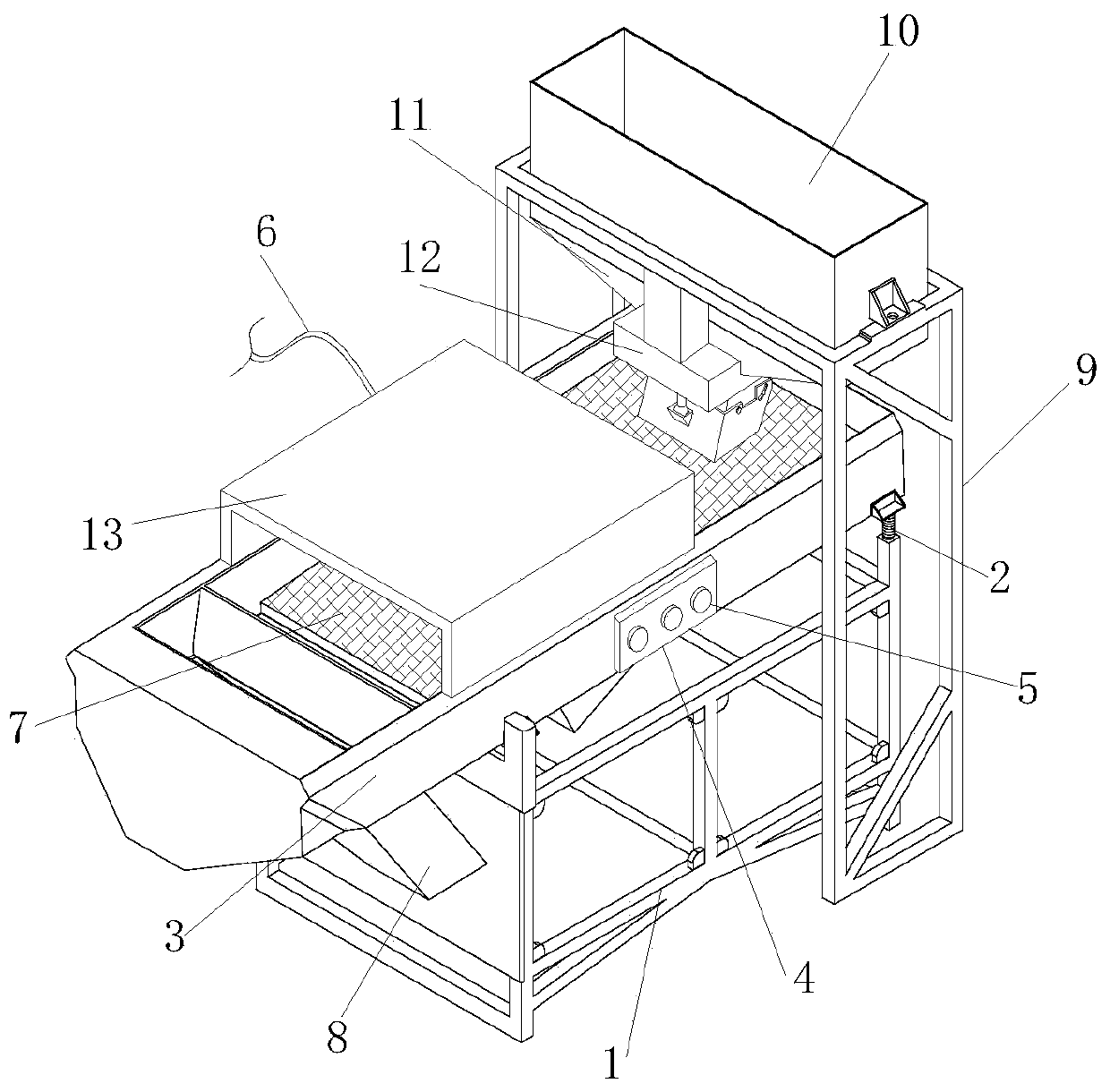

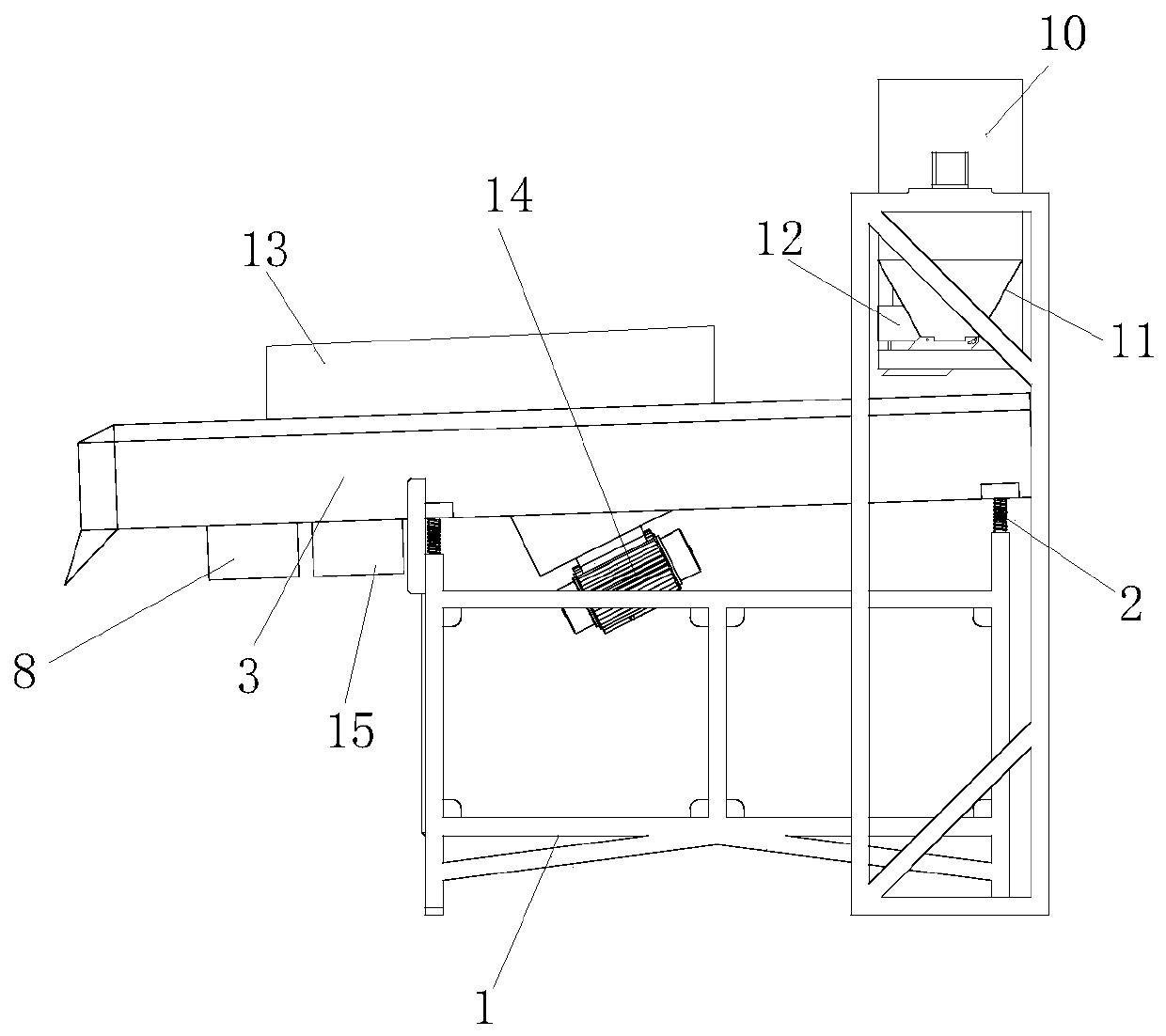

[0040] see figure 1 and figure 2 , the present invention provides a kind of sand and soil screening device for road and bridge construction through improvement, comprising fixed mount 1, spring 2, discharge nozzle 11, vibrating motor 14, second discharge bucket 15, reciprocating pusher 12 and cleaning mechanism 13, The fixed frame 1 is elastically connected to the four corners of the bottom of the screening frame 3 through the spring 2, and the spring 2 is fixedly connected to the bottom of the screening frame 3. The right end of the screening frame 3 is provided with a control panel 4, and the front end of the control panel 4 is equipped with a button 5. The reciprocating pusher 12 is connected with the The front end of the discharge nozzle 11 is fixedly connected, the cleaning mechanism 13 is fixed to the front end of the top of the screening frame 3, the left end of the screening frame 3 is fixed with a power lead 6, the inside of the screening frame 3 is fixed with a scre...

Embodiment 2

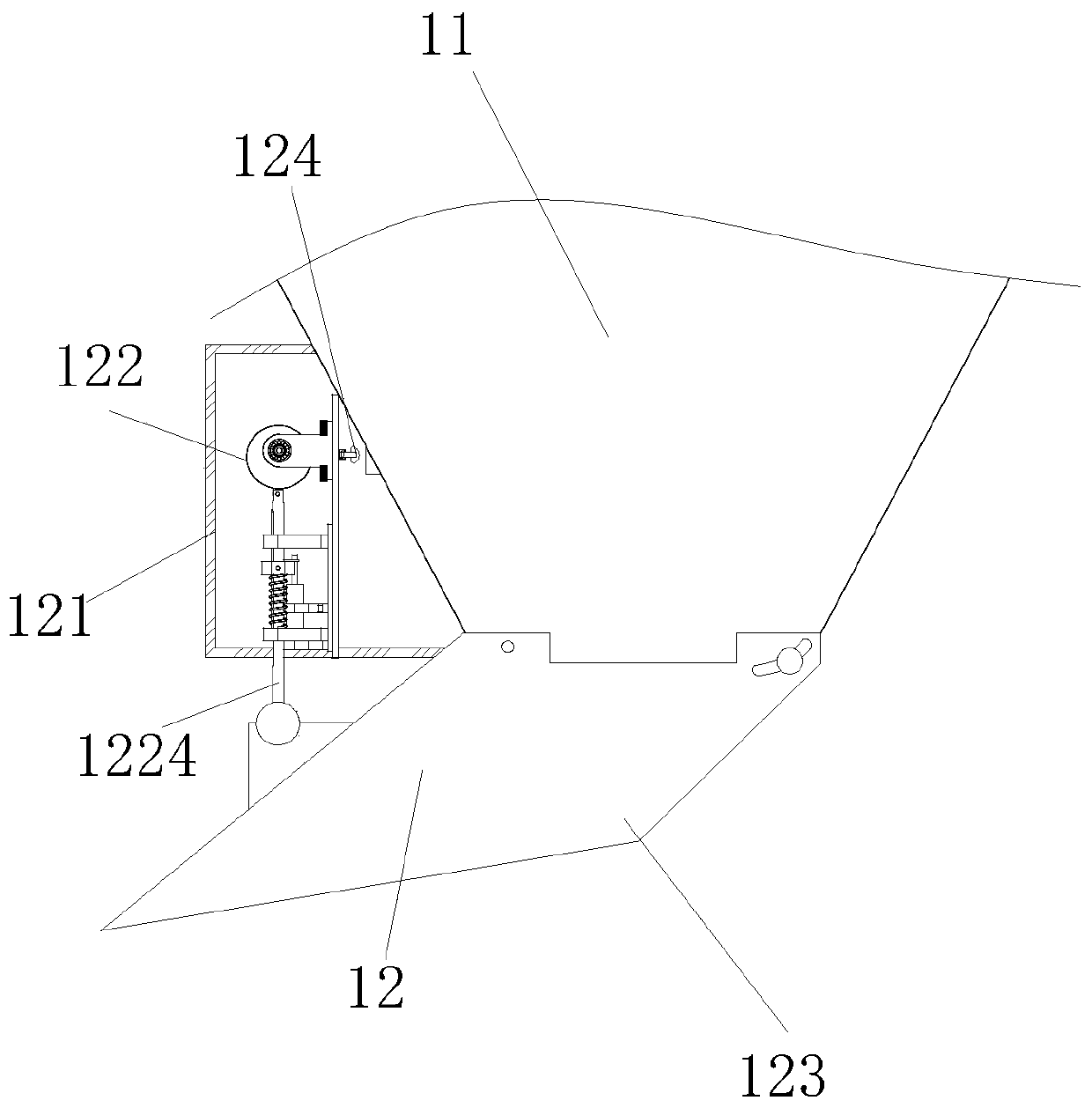

[0049] The present invention provides a sand screening device for road and bridge construction through improvement. The first motor 1222 and the left end of the cam 1223 move eccentrically, which is beneficial to make the cam 1223 push the push rod 1224. The inner side of the receiving block 1232 is arranged There are movable beads 12321, and the movable beads 12321 are fixedly connected with the bottom of the push rod 1224, which is beneficial to make the push rod 1224 move smoothly.

[0050] The present invention provides a sand screening device for road and bridge construction through improvement, and its working principle is as follows;

[0051] First, before use, the sand and soil screening device for road and bridge construction is placed horizontally, so that the fixed frame 1 and the support frame 9 are fixedly supported by the device;

[0052] Second, when in use, connect the external power supply through the power lead 6 to provide power to the device, then place the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com