Automatic intelligent patch pocket machine and patch pocket manufacturing method

A pocket patching machine, an intelligent technology, applied in the sewing machine control device, cloth feeding mechanism, sewing machine components, etc., can solve the problems of low work efficiency and reliability, limited application scope of processed products, etc. Reasonable movement and smooth running effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following describes the embodiments of the present invention in detail, so as to make the technical solution of the present invention easier to understand and grasp, but should not be construed as a limitation of the present invention.

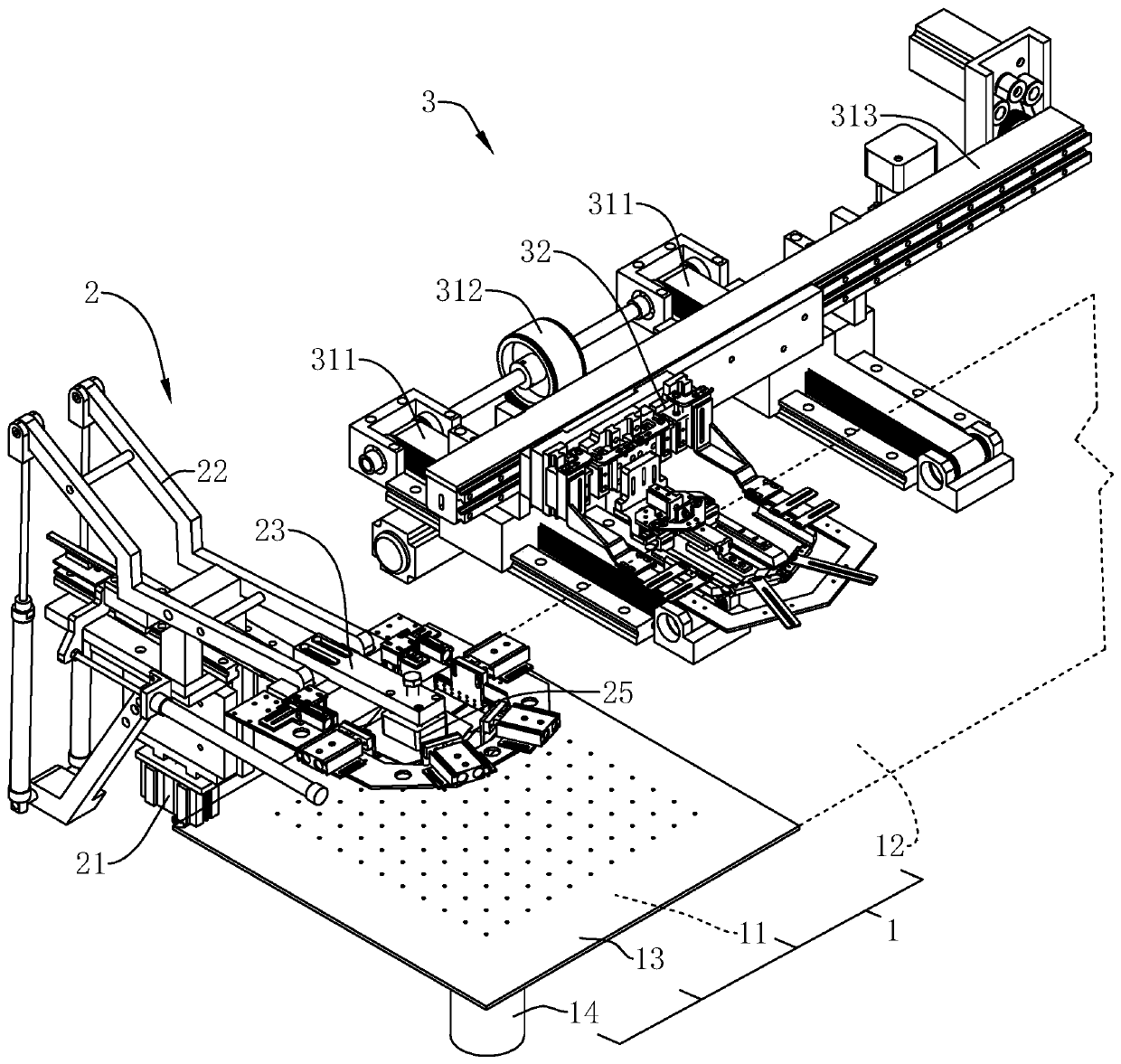

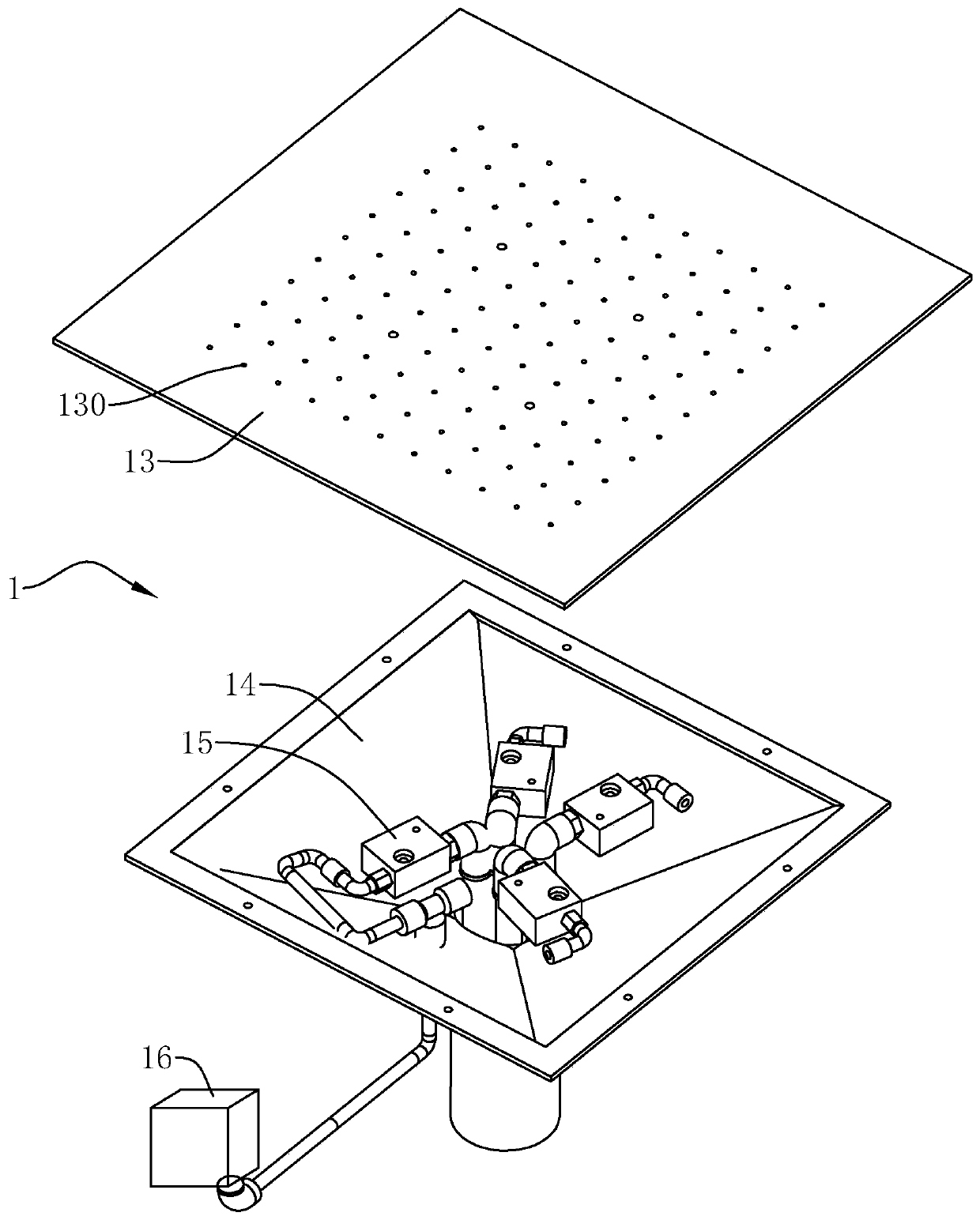

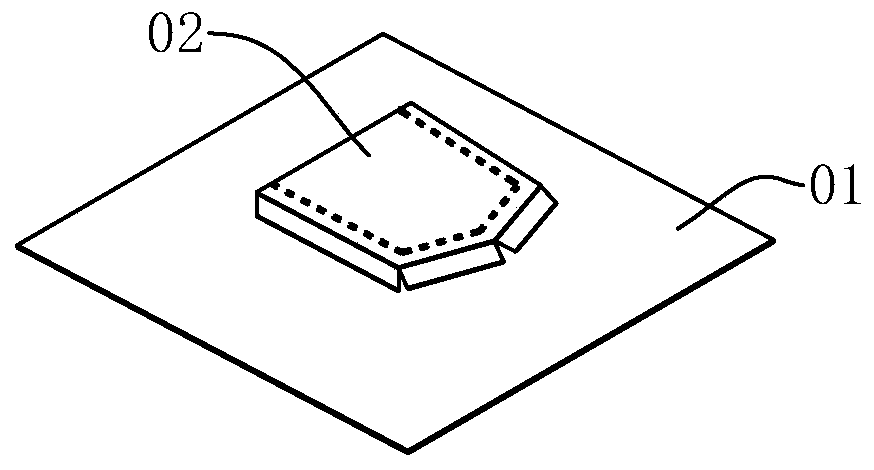

[0040] A kind of automatic intelligent bag sticking machine of the present invention, refer to figure 1 As shown, the working platform 1 is fixedly installed on the machine frame, and is used for absorbing the bottom fabric 01 and the sewing process of the fabric, and has an absorbing and shaping area 11 and a sewing area 12 . The pocket fabric 02 folding mechanism 2 is fixedly installed on the frame above the adsorption and shaping area 11, and is used to support, position, absorb, fold and place the pocket fabric 02. The cloth pressing moving mechanism 3 is installed on the frame, and is used to switch back and forth between the adsorption and shaping area 11 and the sewing area 12, to press the outer frame and inner frame of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com