Tread brake device

A technology of tread braking and rotational connection, applied in railway braking systems, brakes with brakes, transportation and packaging, etc., can solve the problem of accelerating the wear of the piston sealing ring 35', affecting the stability of device operation, and reducing mechanical transmission Efficiency and other issues, to achieve the effect of improving mechanical transmission efficiency, avoiding rigid impact wear, and stable rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

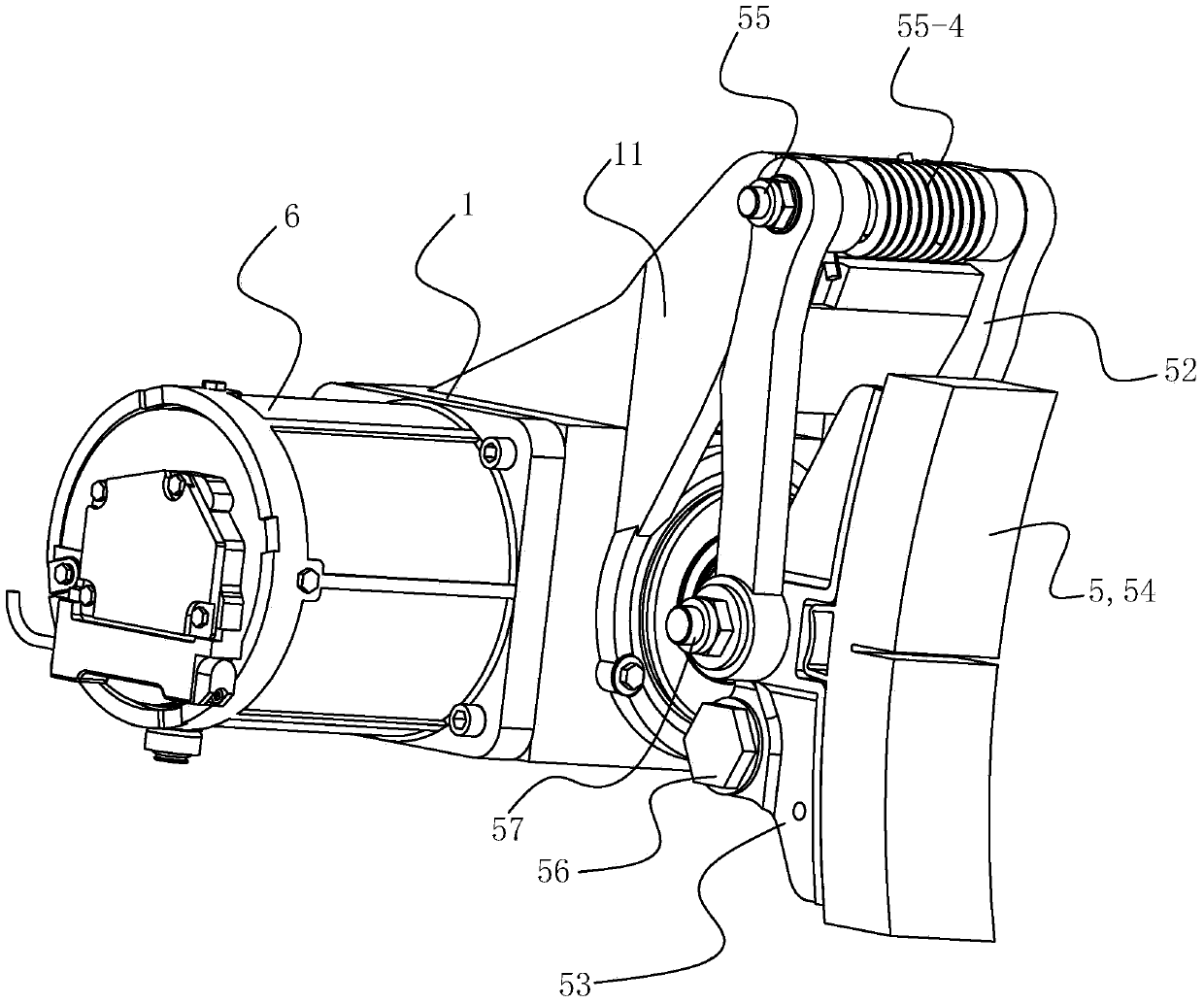

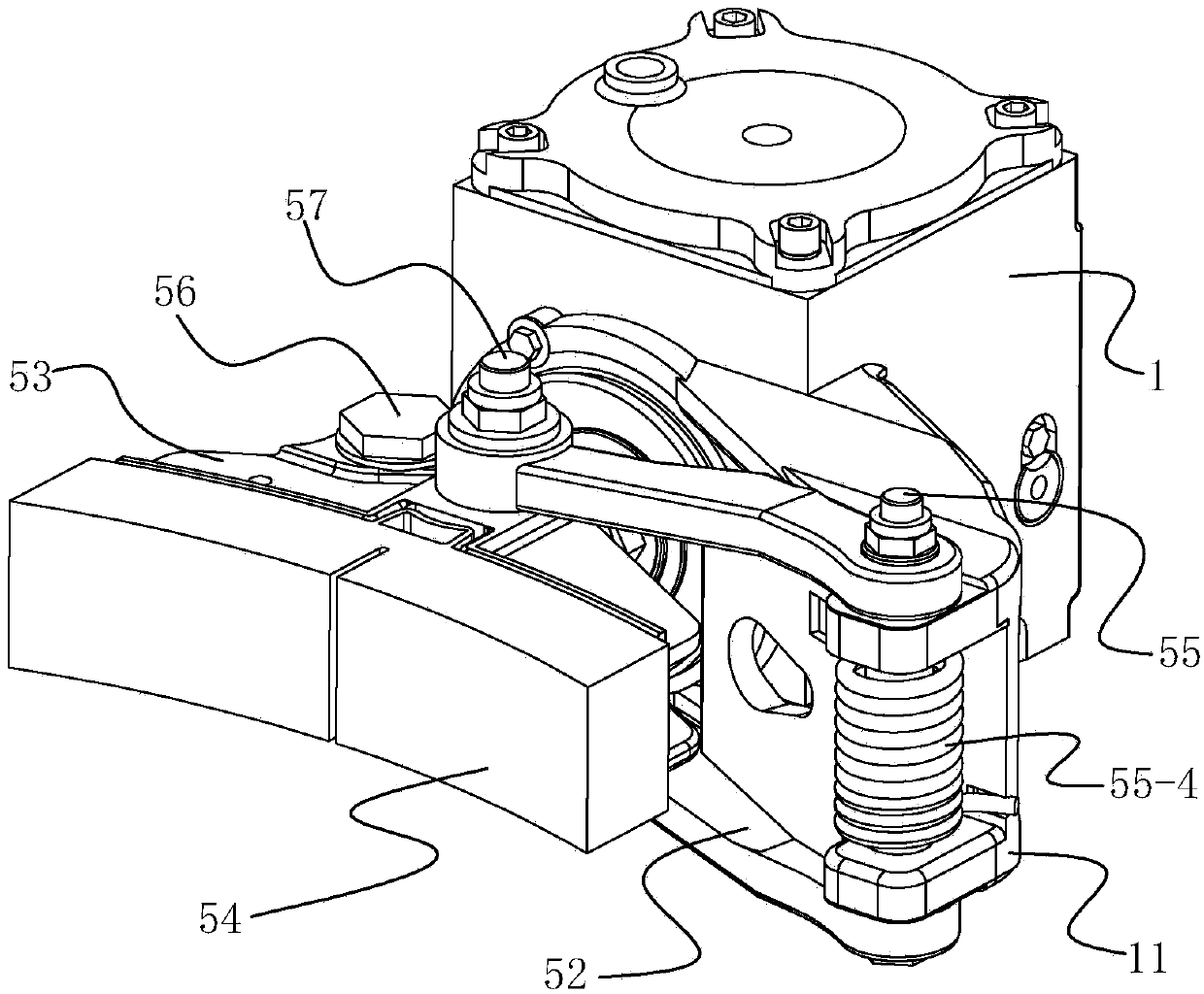

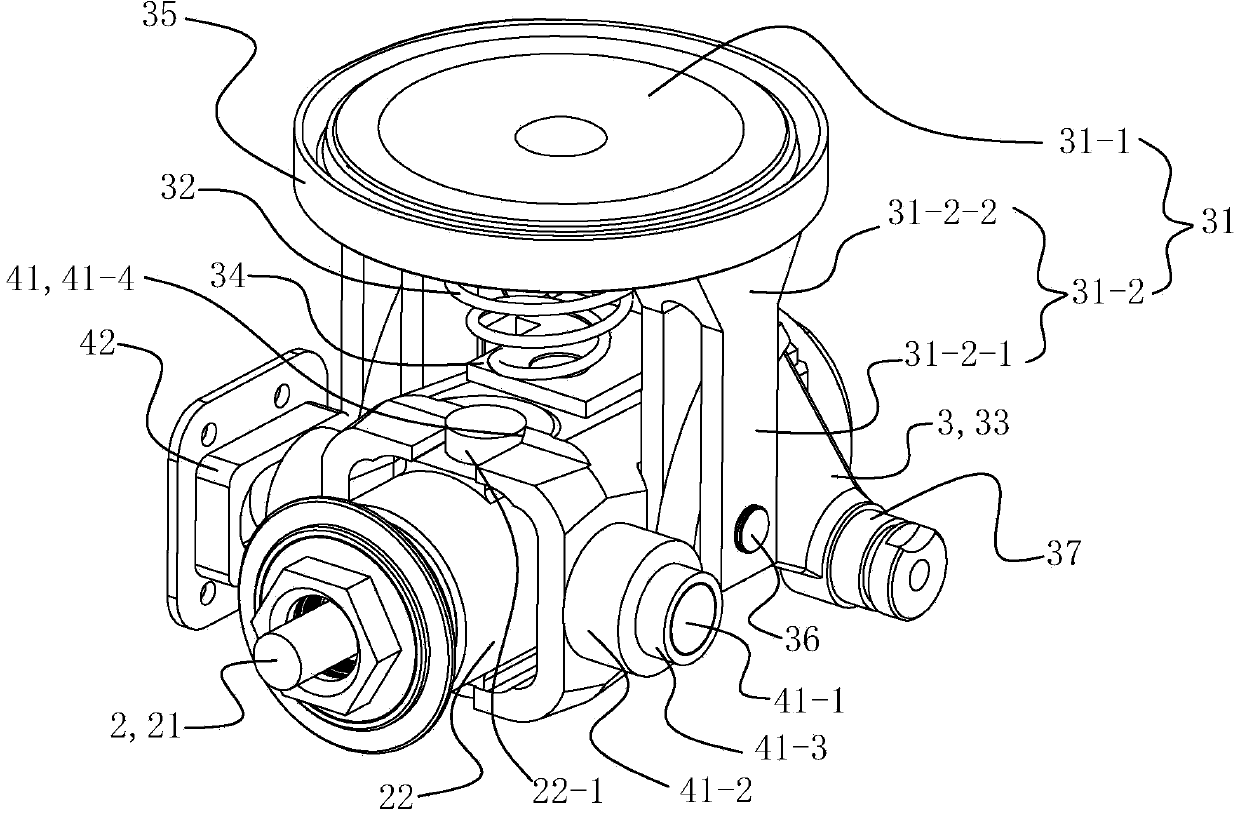

[0041] See figure 2 and image 3 , The tread braking device of this embodiment includes a cylinder body 1, a spindle assembly 2, a force amplification mechanism 3, a thrust ring 41 and a brake shoe swing mechanism 5. The main shaft assembly 2 , the force amplification mechanism 3 and the thrust ring 41 are arranged in the cylinder body 1 . The spindle assembly 2 includes a lead screw 21 and a gap adjustment mechanism 22 . The gap adjustment mechanism 22 is sleeved on the lead screw 21 . The thrust ring 41 is sleeved on the gap adjustment mechanism 22 .

[0042] See Figure 3 to Figure 8 , The force amplification mechanism 3 is a cam mechanism, including a piston 31 and two cams 33 . The piston 31 is elastically disposed in the piston cavity, and the piston 31 includes a piston body 31-1 and two legs 31-2 extending from one side of the piston body 31-1. The rotation center of the cam 33 is rotatably connected to the cylinder body 1, and the edge of the cam 33 is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com