Method for rotationally cutting ultra-short logs

A technology of ultra-short sections and round logs, which is applied in the field of rotary cutting of log sections into veneer, can solve the problem of inability to be rotary cut into thin veneers, and achieve the effects of reducing dosage, protecting ecological environment and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

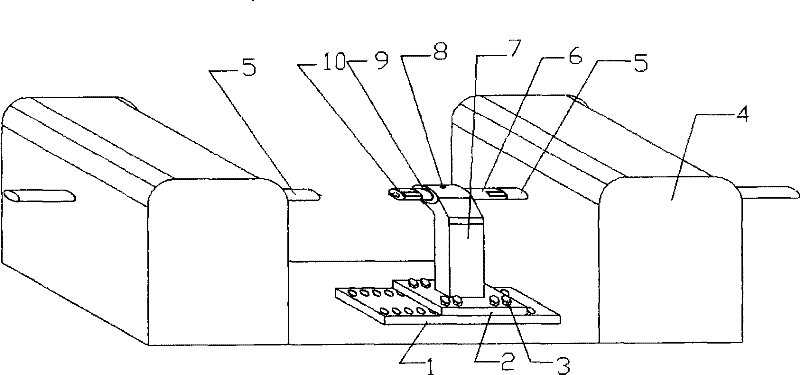

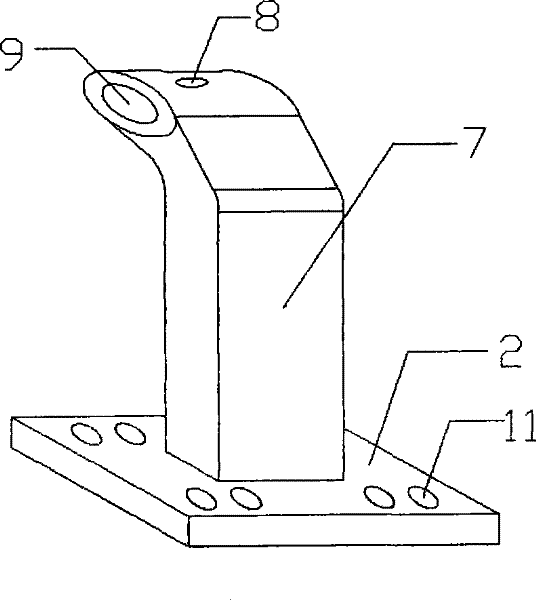

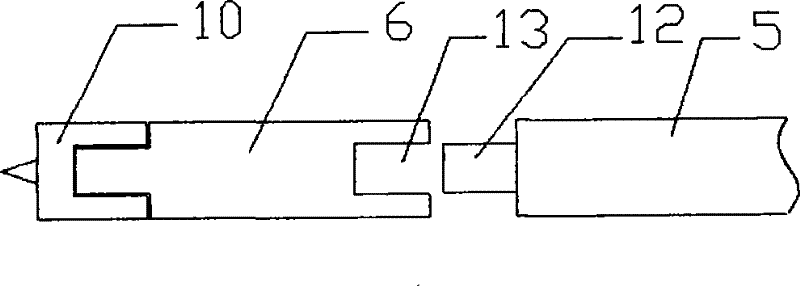

[0010] The present invention as Figure 1 to Figure 3 As shown, a shaft adapter is added in the existing rotary cutting machine body 4, and the shaft adapter is composed of a base 1, a support seat 2, a support 7, a support bearing sleeve 9, and an elongated main shaft 6. The base 1 is a fixed iron plate or a reinforced concrete plate, which is provided with a plurality of screw holes and screws for fixing the bracket seat. A support 7 is connected to the support base 2 . There are 4 to 8 bracket fixing holes 11 arranged in the bracket base 2, which correspond to the fixing screws on the base 1, and are fixed on the base by screwing the nut 3. The upper part of the support 7 is provided with a bearing sleeve 9, and the extended main shaft 6 is sleeved in the bearing sleeve 9, and is connected with the main shaft 5 on the rotary cutting machine body. The top of the bearing sleeve is provided with a lubricating oil inlet hole 8 for lubrication. Oil enters the bearing housing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com