Vertical hole boring machine

A boring machine and vertical technology, applied in the field of vertical boring machines, can solve the problems of waste, limited space and complex location conditions, etc., and achieve the effects of improving work efficiency, flexibility and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

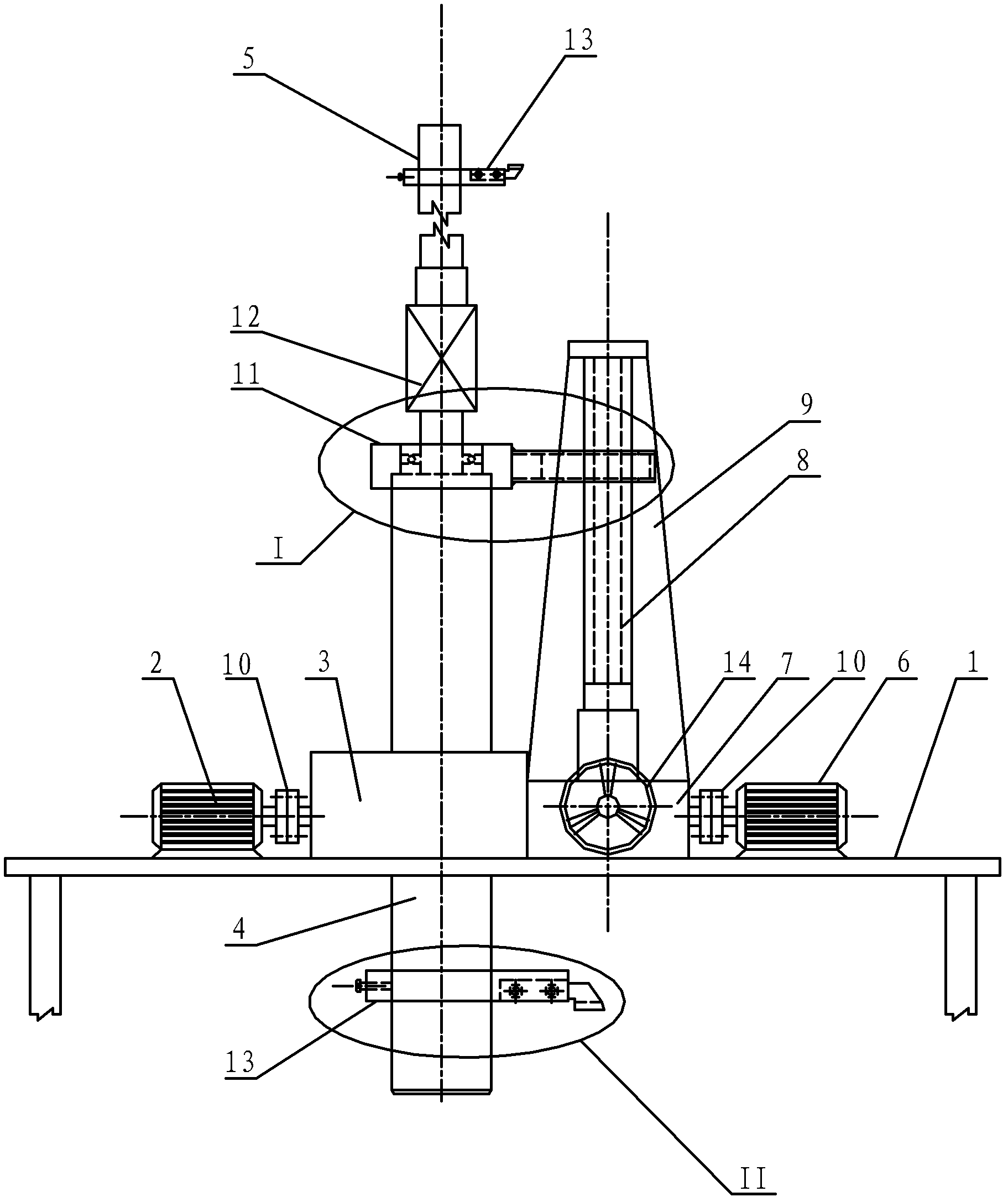

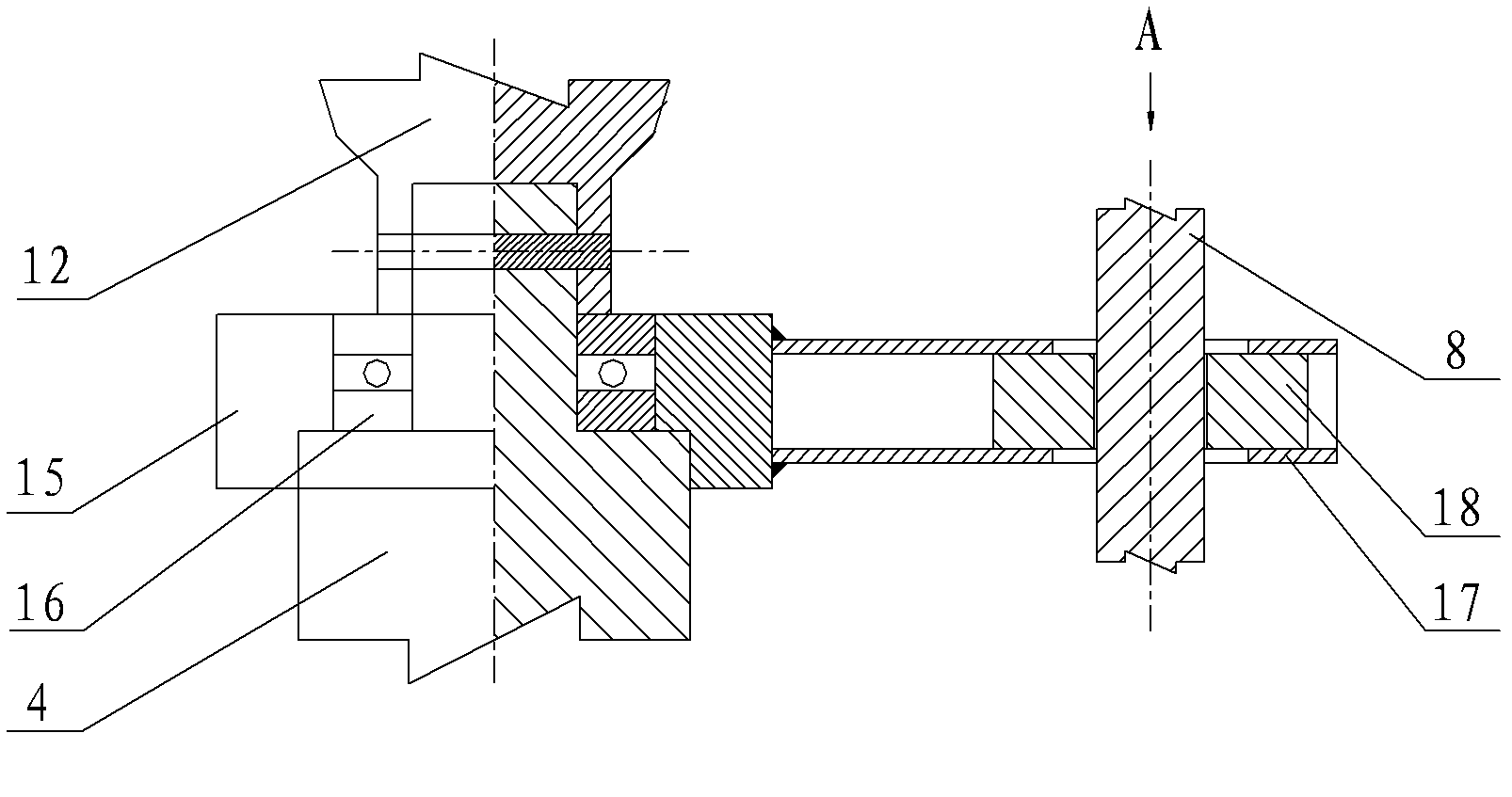

[0030] The vertical boring machine mainly includes a boring machine base 1, a boring bar driving motor 2 installed on the boring machine base 1, a boring knife feeding motor 6 and a boring knife feeding driving rod 8, and also includes a boring bar 4 and Boring mechanism 13; the boring bar drive motor 2 drives the boring bar 4 and the boring bar mechanism 13 installed on it to rotate; the boring bar feed motor 6 drives the boring bar feed drive rod 8 to rotate, and the boring bar 4 is divided into The fixed boring bar and the movable boring bar 5 are two parts, and the fixed boring bar and the movable boring bar 5 are connected by a universal coupling 12 .

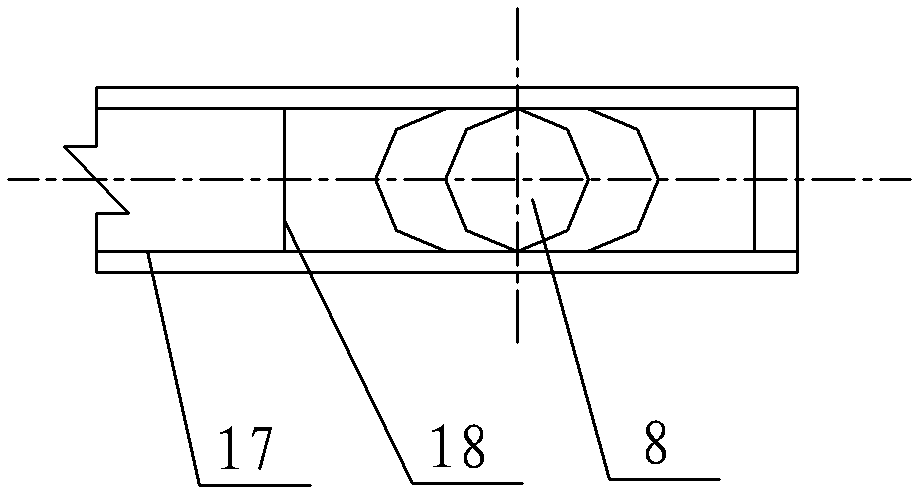

[0031] The boring tool feed drive rod 8 is a screw rod, which is installed on the boring machine base 1 through a support frame 9, and is connected with a fixed boring bar through a transmission mechanism 11; The steel ring 15 on the rod, the thrust bearing 16 fixedly installed in the steel ring 15, the steel pipe 17 fixed...

Embodiment 2

[0034] The vertical boring machine mainly includes a boring machine base 1, a boring bar driving motor 2 installed on the boring machine base 1, a boring knife feeding motor 6 and a boring knife feeding driving rod 8, and also includes a boring bar 4 and Boring mechanism 13; the boring bar drive motor 2 drives the boring bar 4 and the boring bar mechanism 13 installed on it to rotate; the boring bar feed motor 6 drives the boring bar feed drive rod 8 to rotate, and the boring bar 4 is divided into The fixed boring bar and the movable boring bar 5 are two parts, and the fixed boring bar and the movable boring bar 5 are connected by a universal coupling 12 .

[0035] The boring tool feed drive rod 8 is a screw rod, which is installed on the boring machine base 1 through a support frame 9, and is connected with a fixed boring bar through a transmission mechanism 11; The steel ring 15 on the rod, the thrust bearing 16 fixedly installed in the steel ring 15, the steel pipe 17 fixed...

Embodiment 3

[0046] The vertical boring machine mainly includes a boring machine base 1, a boring bar driving motor 2 installed on the boring machine base 1, a boring knife feeding motor 6 and a boring knife feeding driving rod 8, and also includes a boring bar 4 and Boring mechanism 13; the boring bar drive motor 2 drives the boring bar 4 and the boring bar mechanism 13 installed on it to rotate; the boring bar feed motor 6 drives the boring bar feed drive rod 8 to rotate, and the boring bar 4 is divided into The fixed boring bar and the movable boring bar 5 are two parts, and the fixed boring bar and the movable boring bar 5 are connected by a universal coupling 12 .

[0047] The boring tool feed drive rod 8 is a screw rod, which is installed on the boring machine base 1 through a support frame 9, and is connected with a fixed boring bar through a transmission mechanism 11; The steel ring 15 on the rod, the thrust bearing 16 fixedly installed in the steel ring 15, the steel pipe 17 fixed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com