Method and machine for treating textile fabrics with an adjustable air flow

An adjustable, air-treating technology, used in textiles and papermaking, liquid/gas/vapor jet-propulsion fabrics, thin material processing, etc., can solve problems such as reducing the strength of impact, and achieve the effect of reducing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

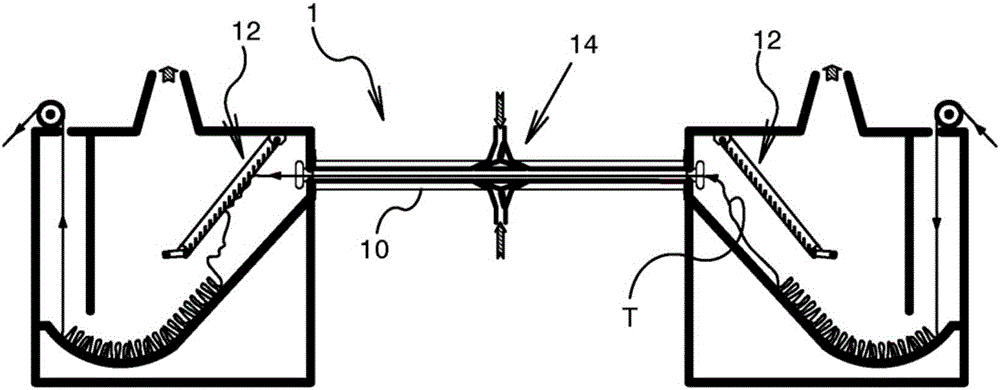

[0025] figure 1 Shows a schematic longitudinal section through a continuous open diverter 1 equipped with a channel 10 of rectangular section for pneumatically conveying the fabric T and equipped with an impingement grid 12 facing the opening of the channel .

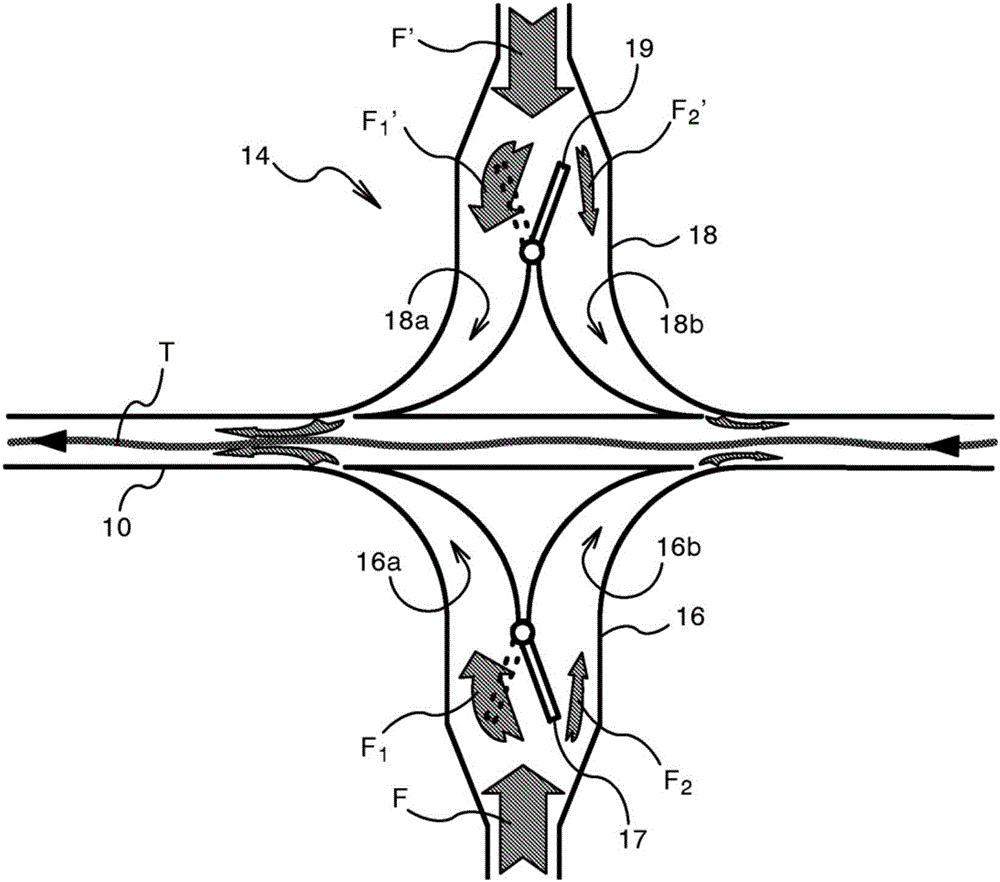

[0026] A system 14 for injecting air into the channel is located approximately in the middle of the channel 10 and generally above and below the fabric. The gas flow is produced by means of per se known type not shown.

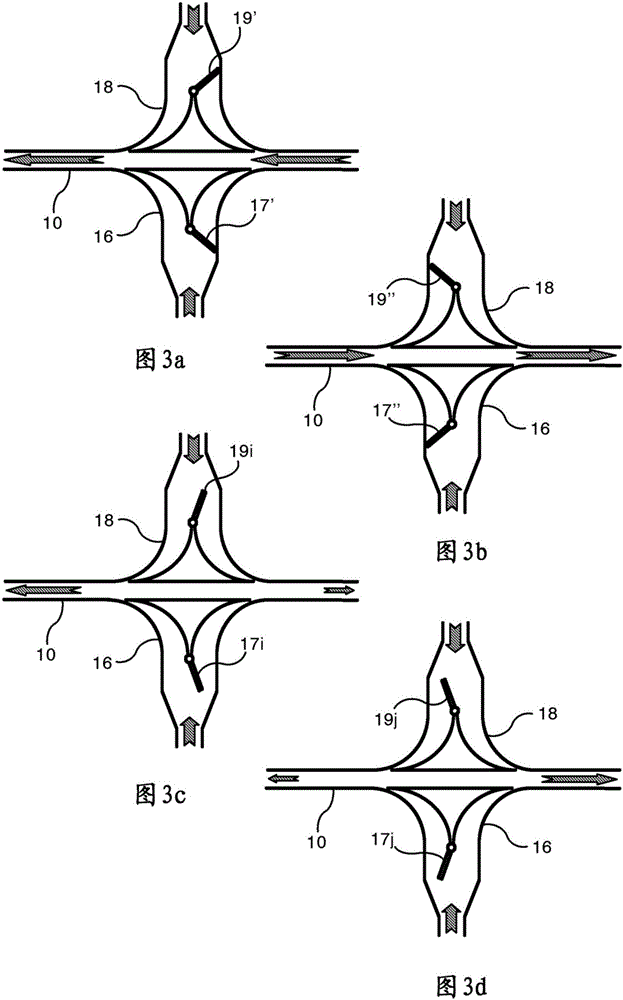

[0027] The system 14 - in figure 2 shown in enlarged and more detailed manner in -comprising two directional valves 16, 18 each having two passages 16a, 16b and 18a, 18b, the passages 16a, 16b and 18a, 18b are suitably oriented to direct airflow into the channel in one direction or the other.

[0028] According to the invention, each valve also comprises an adjustable flap 17, 19 adapted to completely or partially close the inlets to the passages 16a, 16b and 18a, 18b.

[0029] Thus, the valves 16...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com