Method for integrating heat conductor with heat dissipating fin

a heat conductor and heat dissipating fin technology, applied in the direction of tubular elements, lighting and heating apparatus, metal-working apparatus, etc., can solve the problems of increasing thermal resistance, affecting the outside appearance, and the heat tube cannot pass the aperture on each heat dissipating fin very smoothly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will now be described more specifically with reference to the following embodiments. It is to be noted that the following descriptions of preferred embodiments of this invention are presented herein for purpose of illustration and description only; it is not intended to be exhaustive or to be limited to the precise form disclosed.

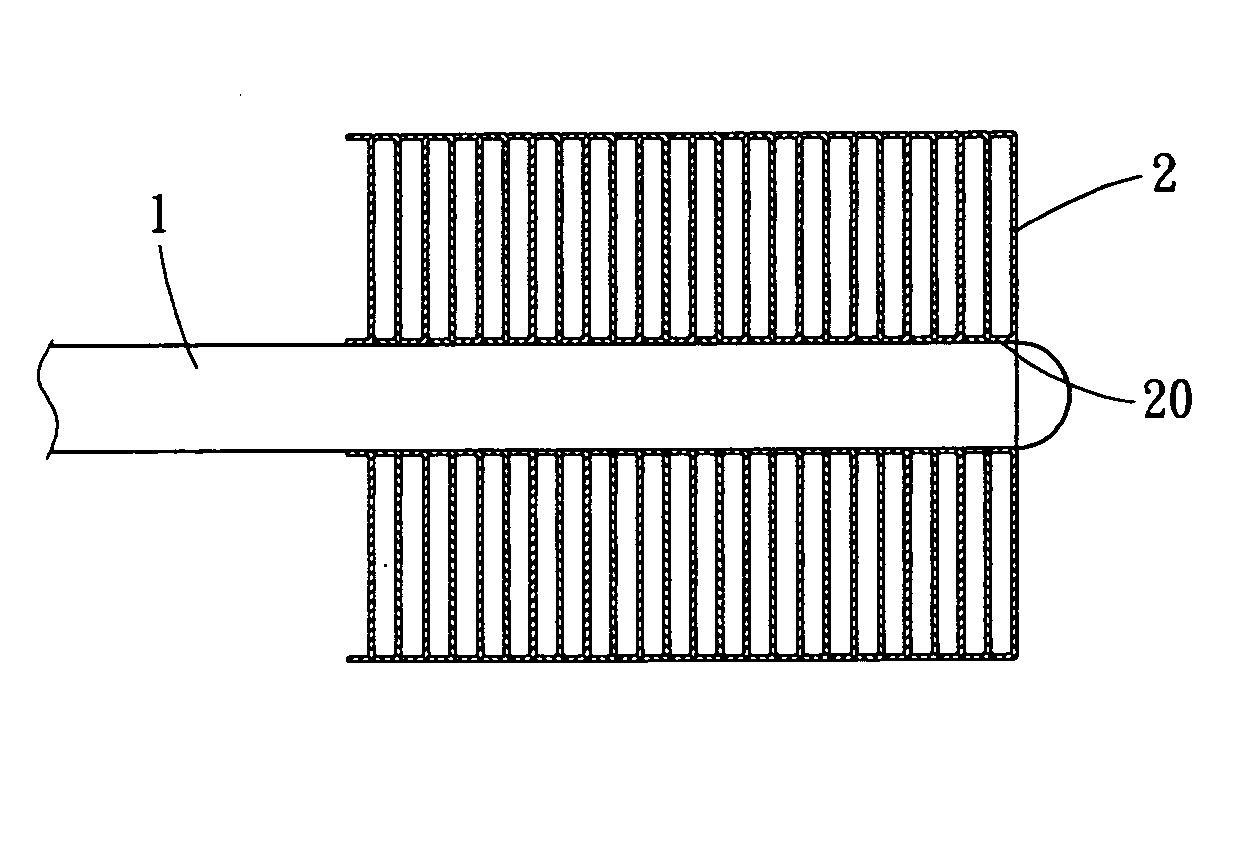

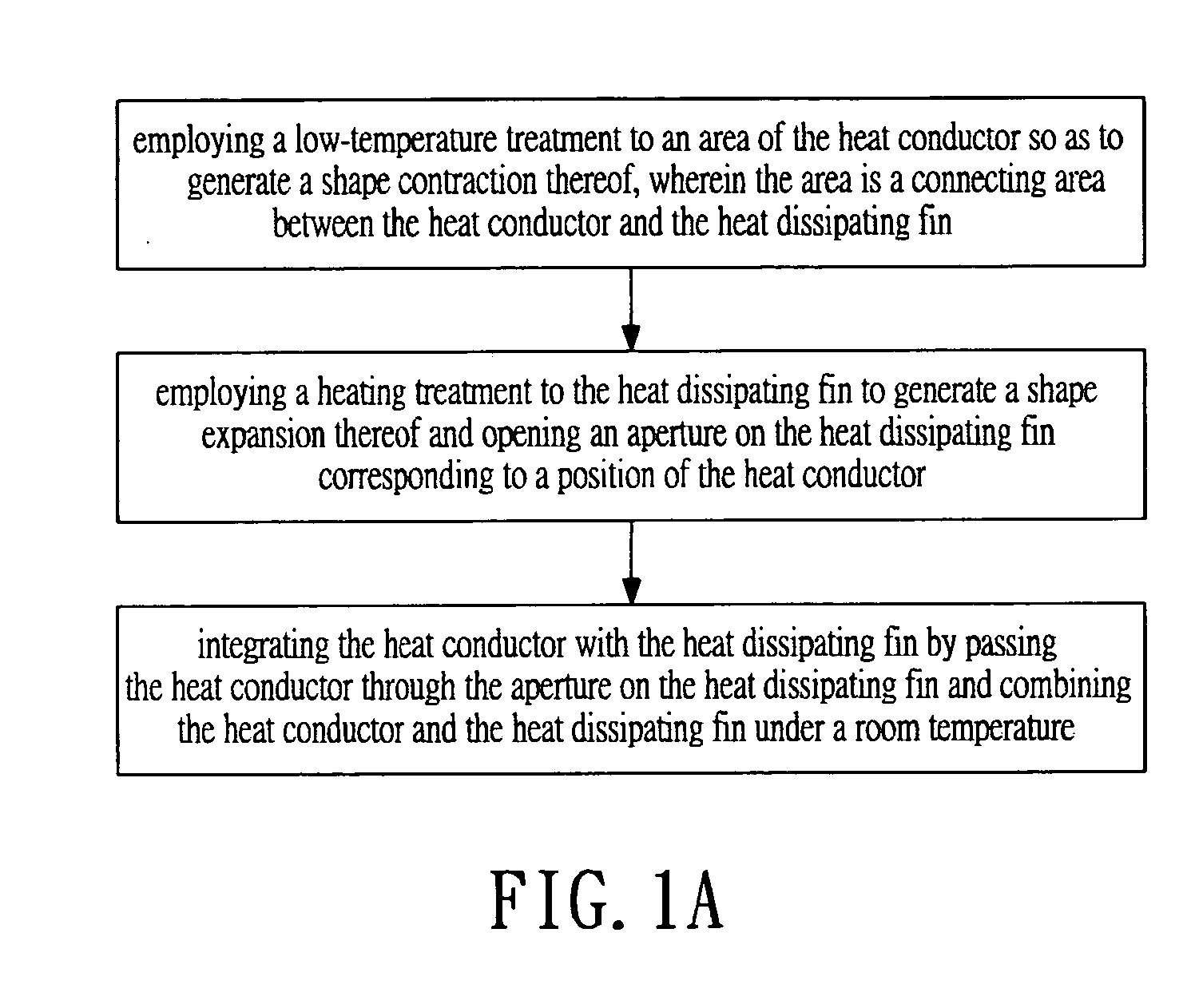

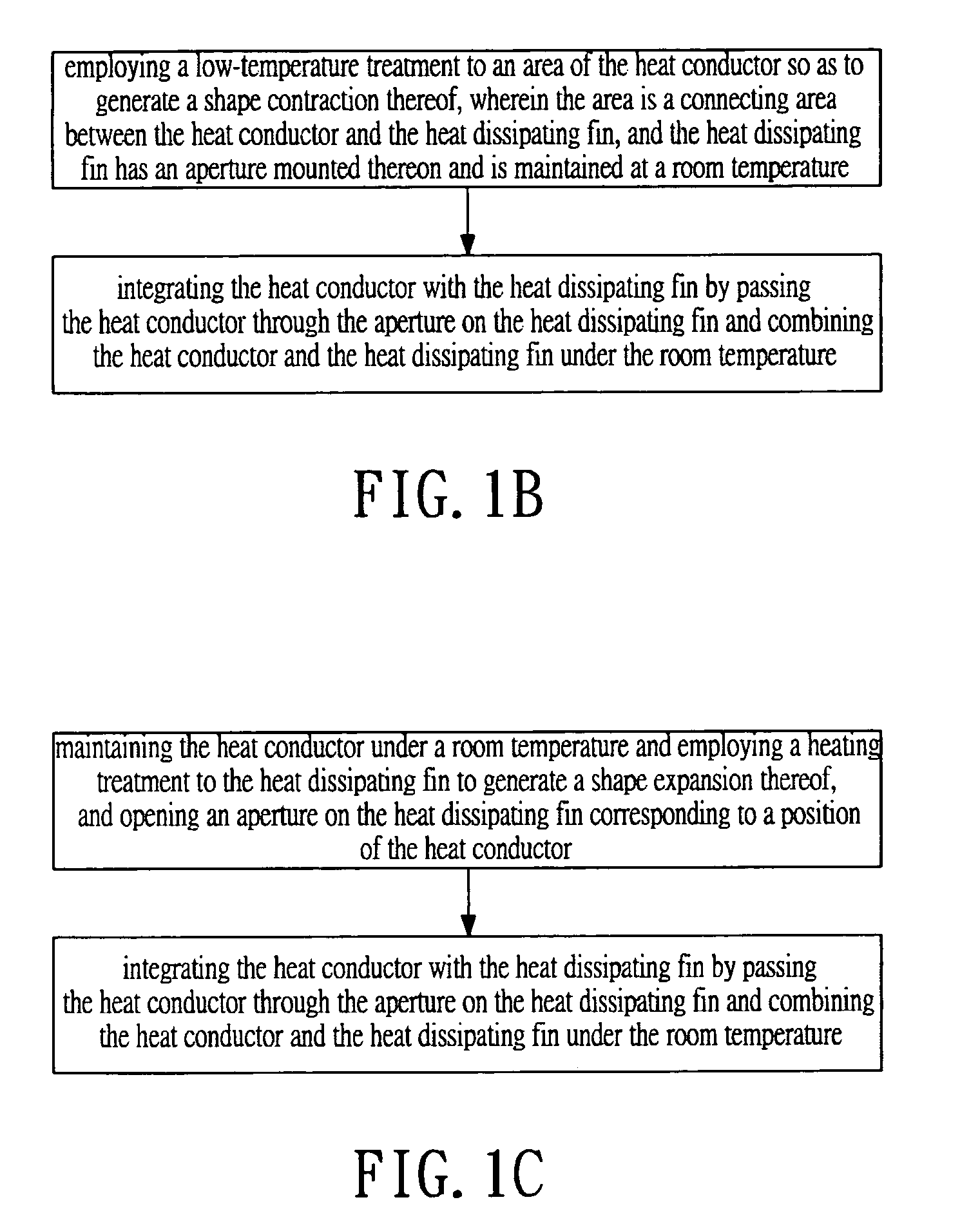

[0031] Please refer to FIGS. 1A and 2-4. FIG. 1A is a flow chart illustrating the steps for integrating a heat conductor with a heat dissipating fin according to the first preferred embodiment of the present invention. FIG. 2 is a diagram showing the heat conductor and the heat dissipating fin before combined. FIG. 3 is a diagram showing the heat tube and the heat dissipating fin after combined. FIG. 4 is a sectional diagram showing the heat dissipating device combined by the heat tube and a plurality of heat dissipating fin. A method for integrating a heat conductor with a heat dissipating fin is provided in the present invent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com