Rotary type oily particle filling material box sealing mechanism

A sealing mechanism, rotary technology, applied in packaging, liquid materials, transportation and packaging, etc., can solve problems such as product quality, material leakage, and small contact area affecting equipment cleanliness, achieve simple structure, improve sealing, and improve Contact dense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

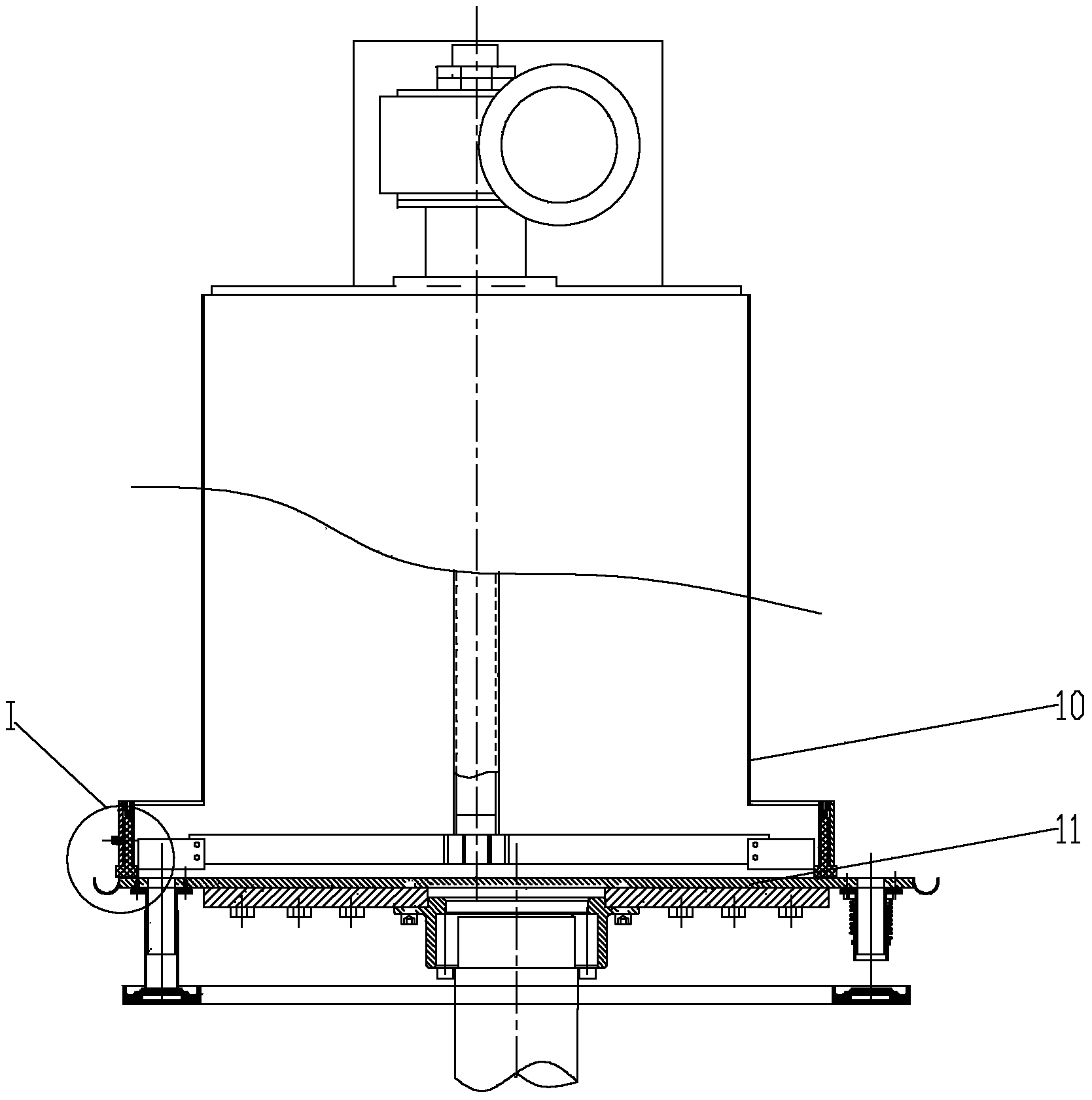

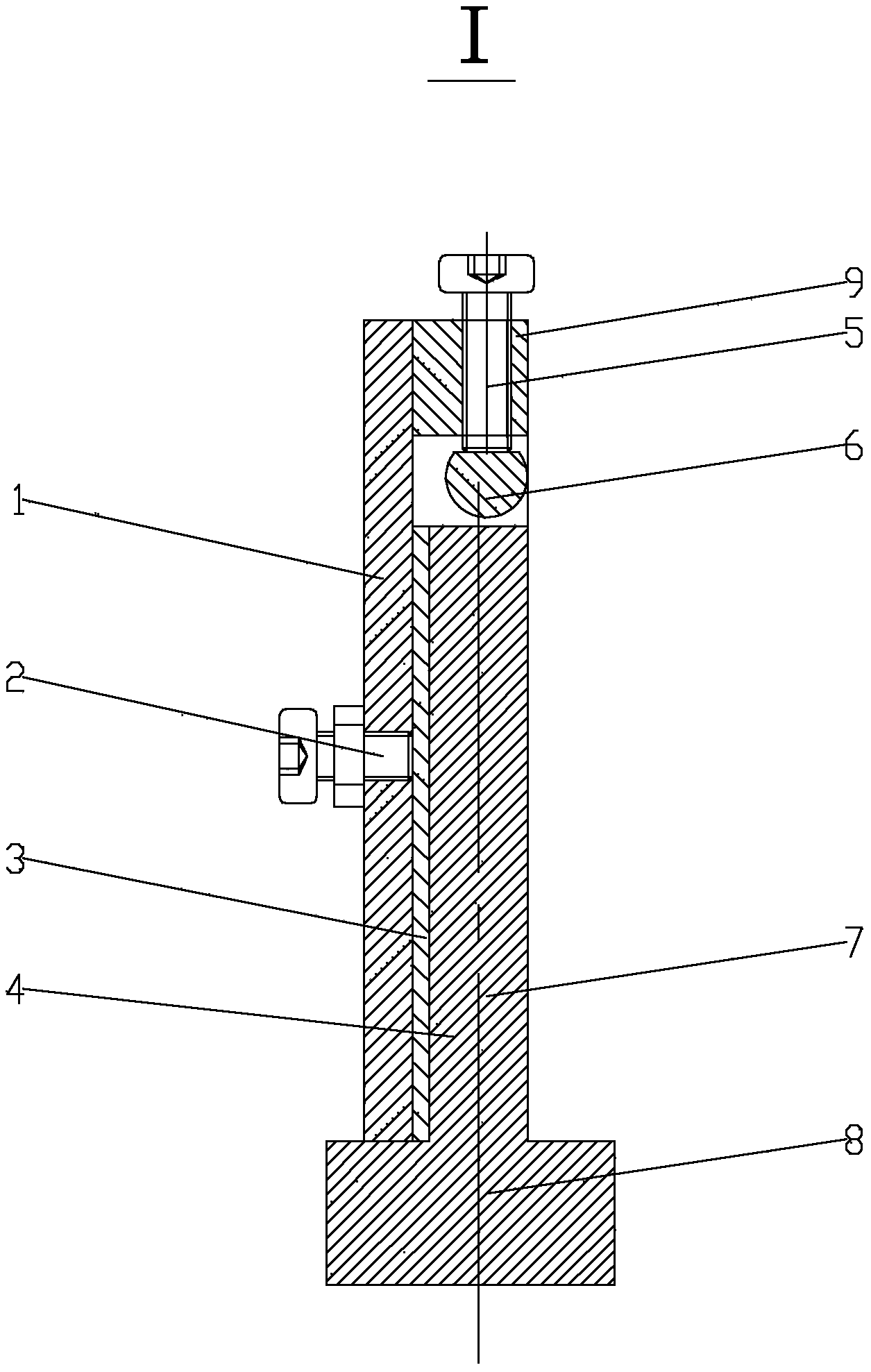

[0019] Such as Figure 1~2 As shown, the present invention mainly comprises outer pressing plate 1, side adjusting bolt 2, inner pressing plate 3, seal ring 4, upper adjusting screw 5, upper pressing plate 6 and top side pressing plate 9, outer pressing plate 1 is circular ring, outer pressing plate 1 The inner ring is provided with a sealing ring 4 and a top side pressing plate 9 , and the top side pressing plate 9 is located directly above the sealing ring 4 .

[0020] The top side pressing plate 9 is provided with a plurality of upper adjusting screws 5 , and the plurality of upper adjusting screws 5 are evenly distributed along the circumferential direction of the top side pressing plate 9 . The sealing ring 4 can be pressed against the fixed plate 11 of the quantitative valve in the height direction by tightening a plurality of upper adjusting sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com