Patents

Literature

77results about How to "Clean out" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

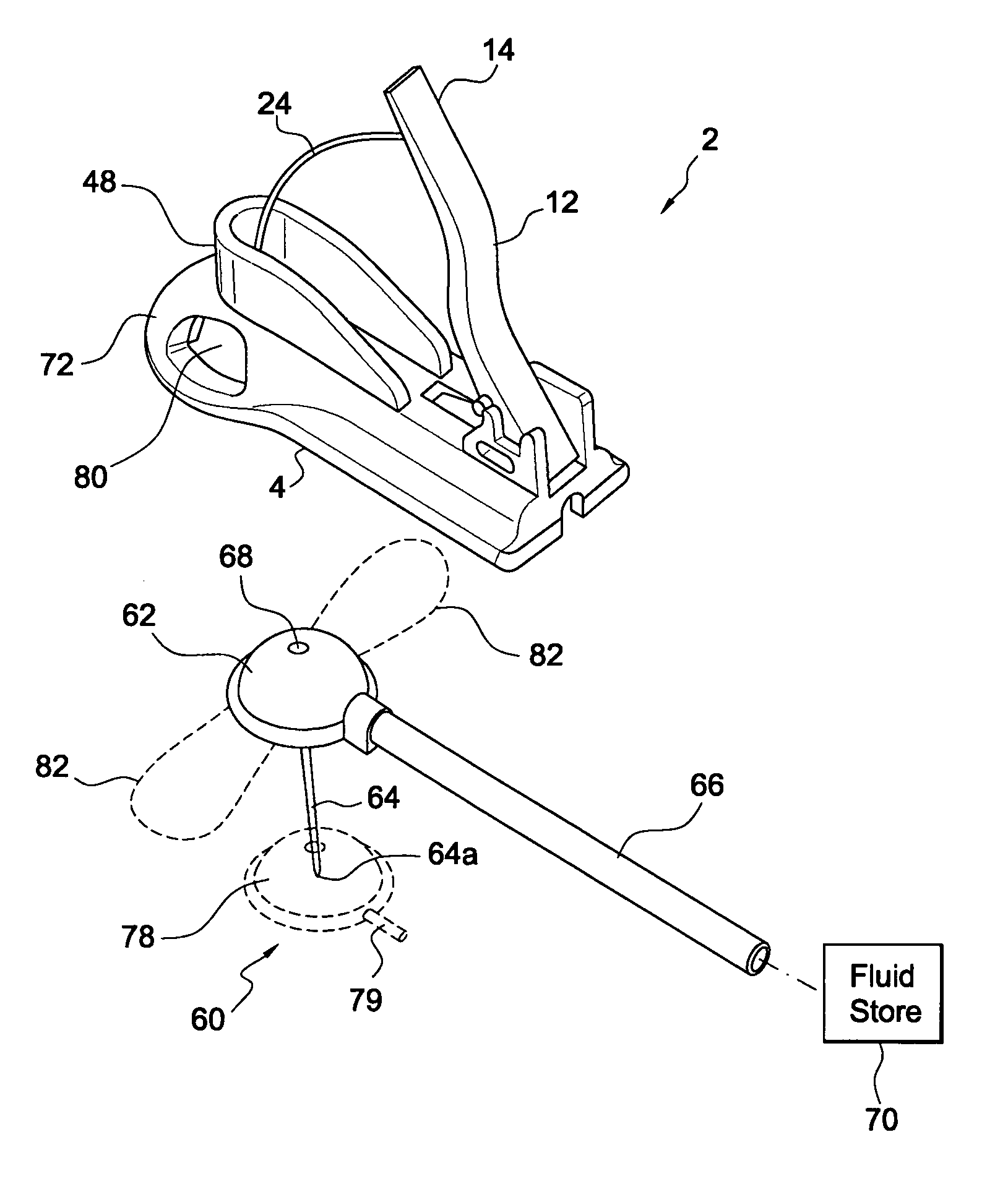

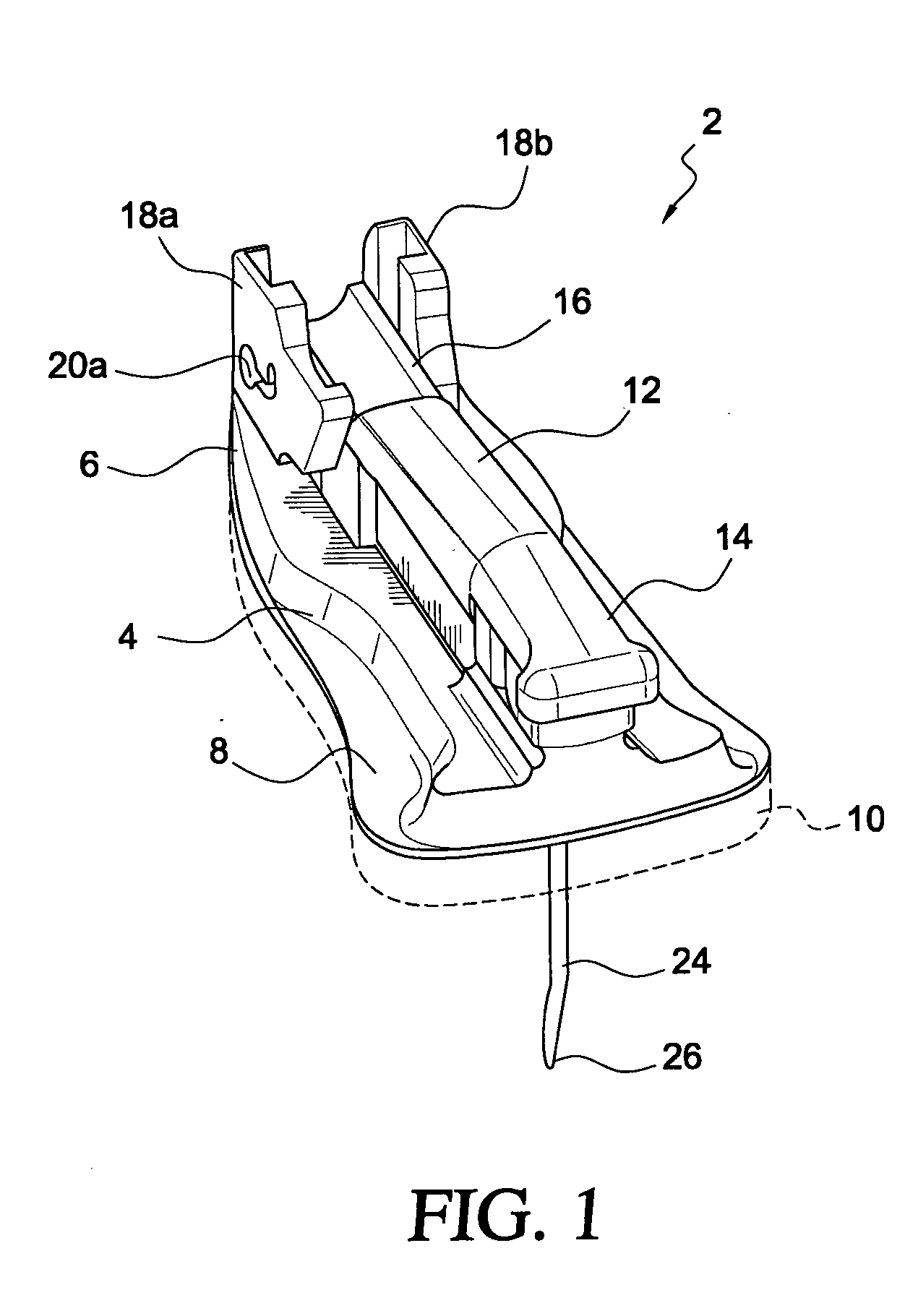

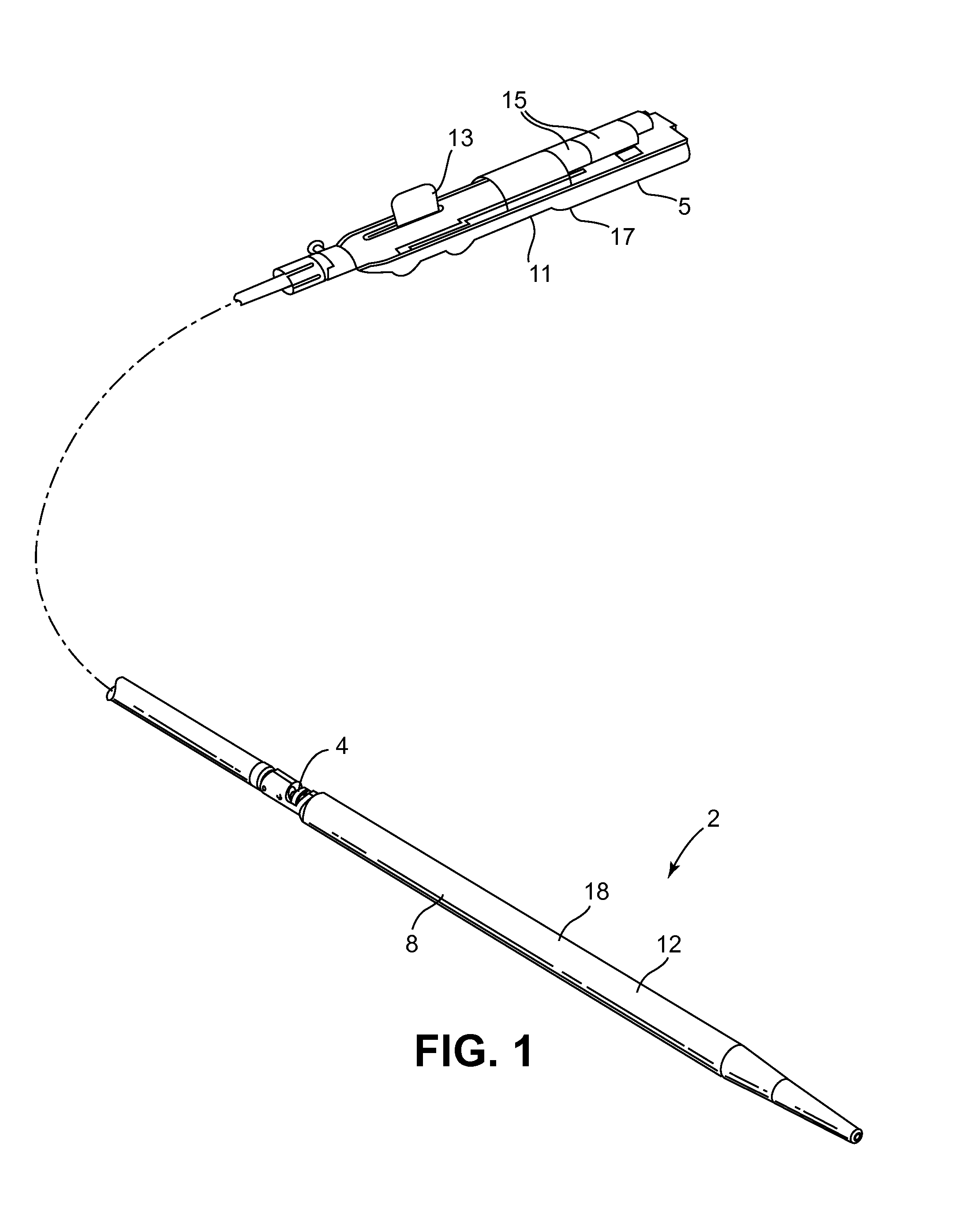

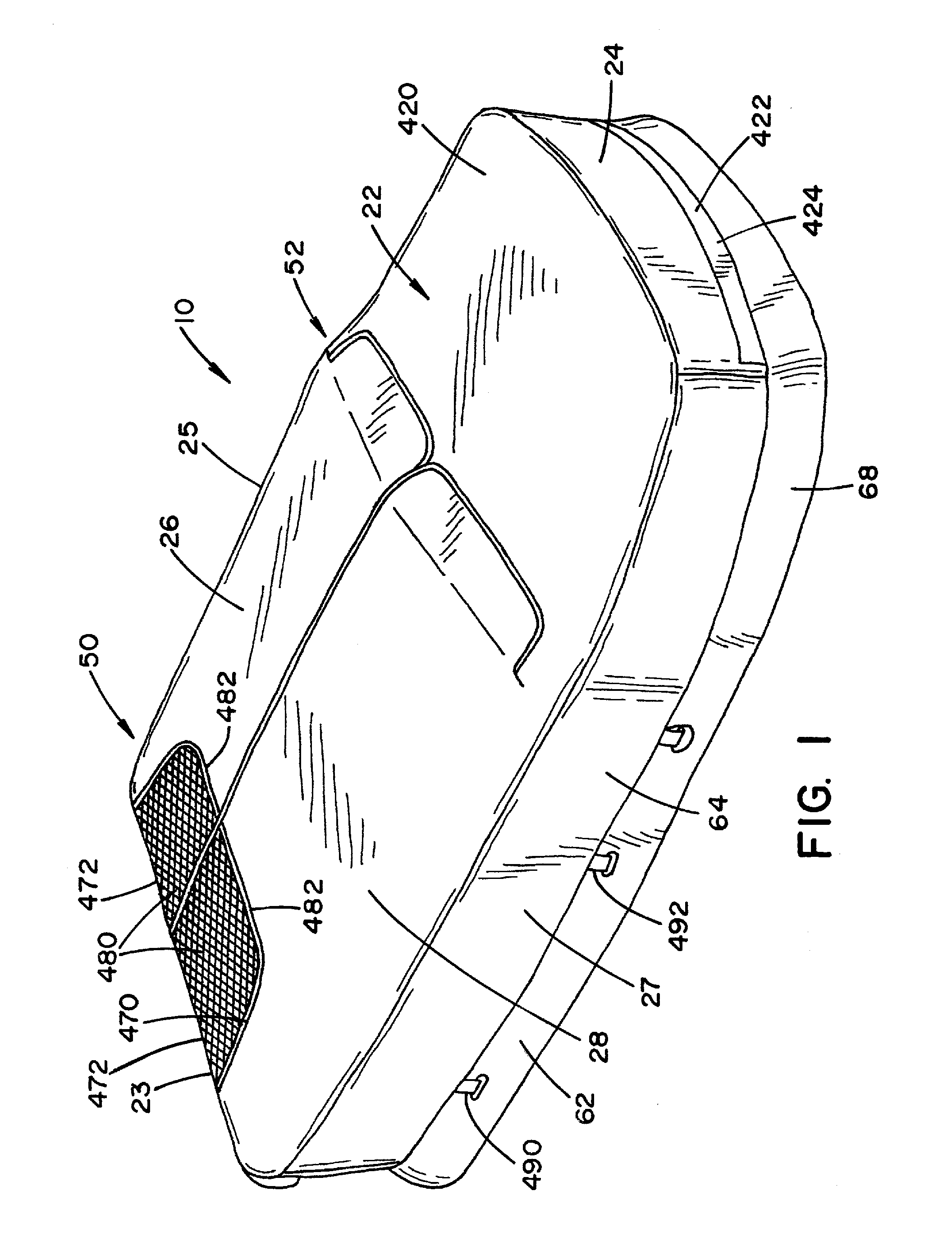

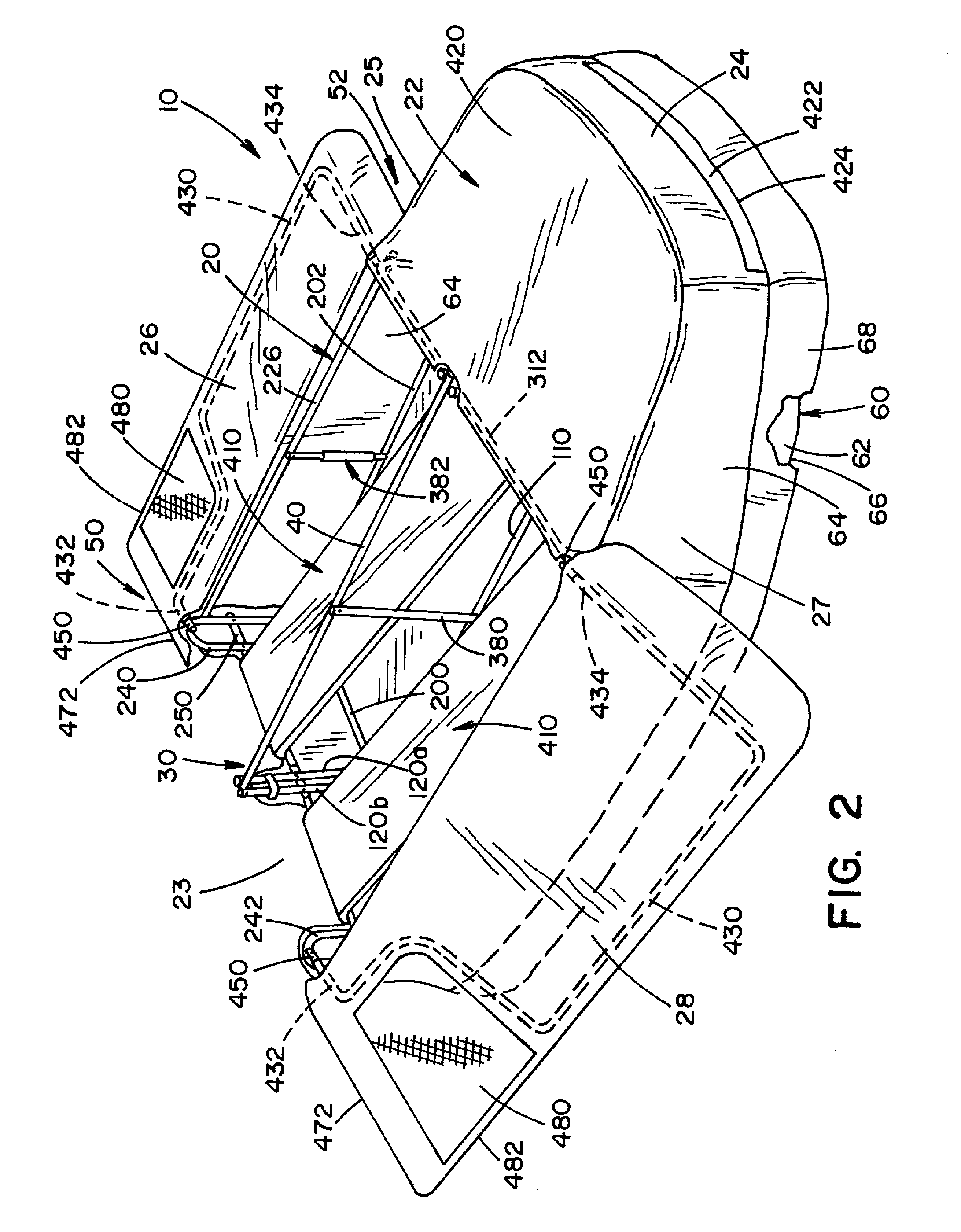

Portal access device with removable sharps protection

ActiveUS20070149920A1Safe removalEasily gain accessMedical devicesInfusion needlesDistal portionLocking mechanism

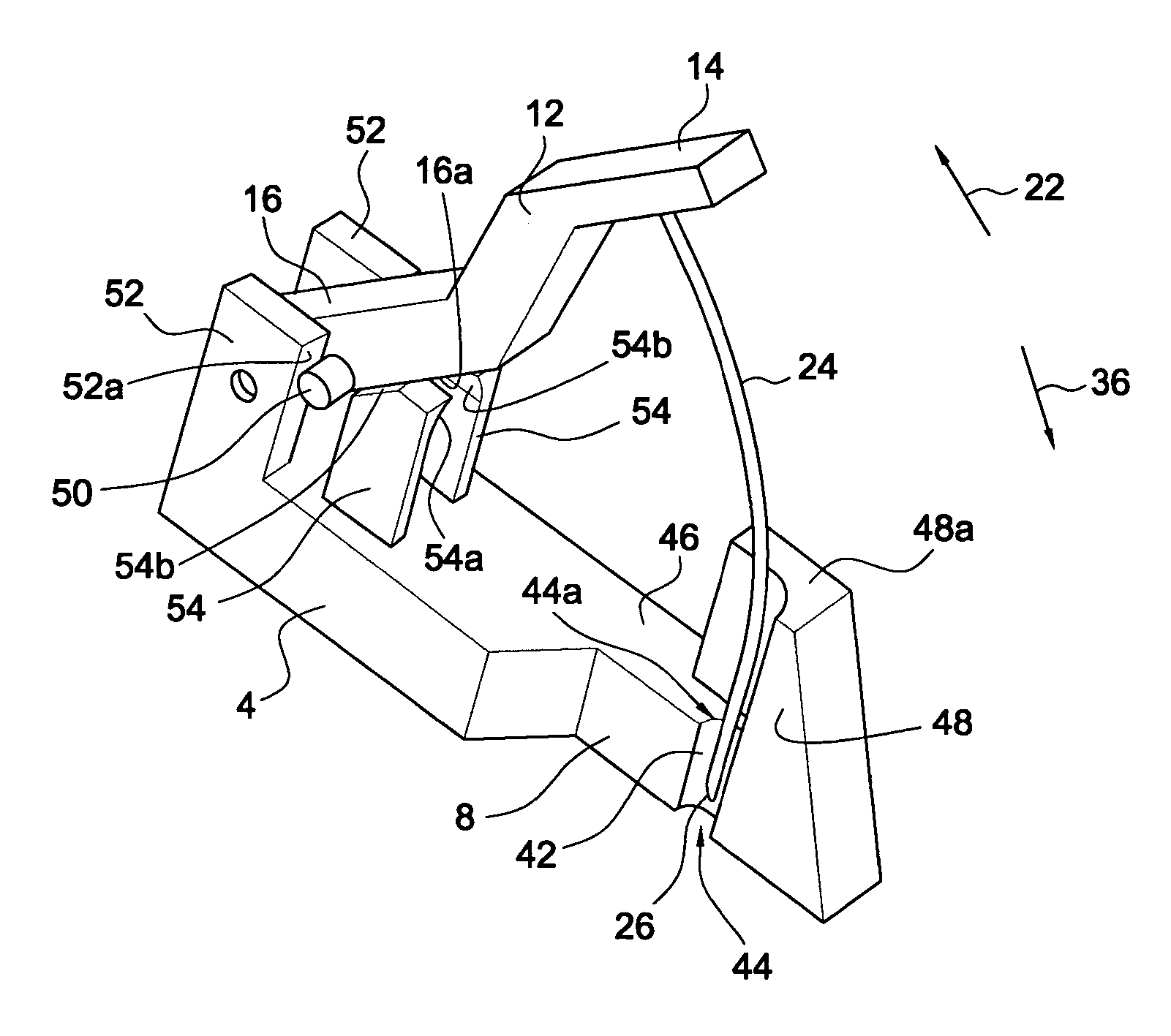

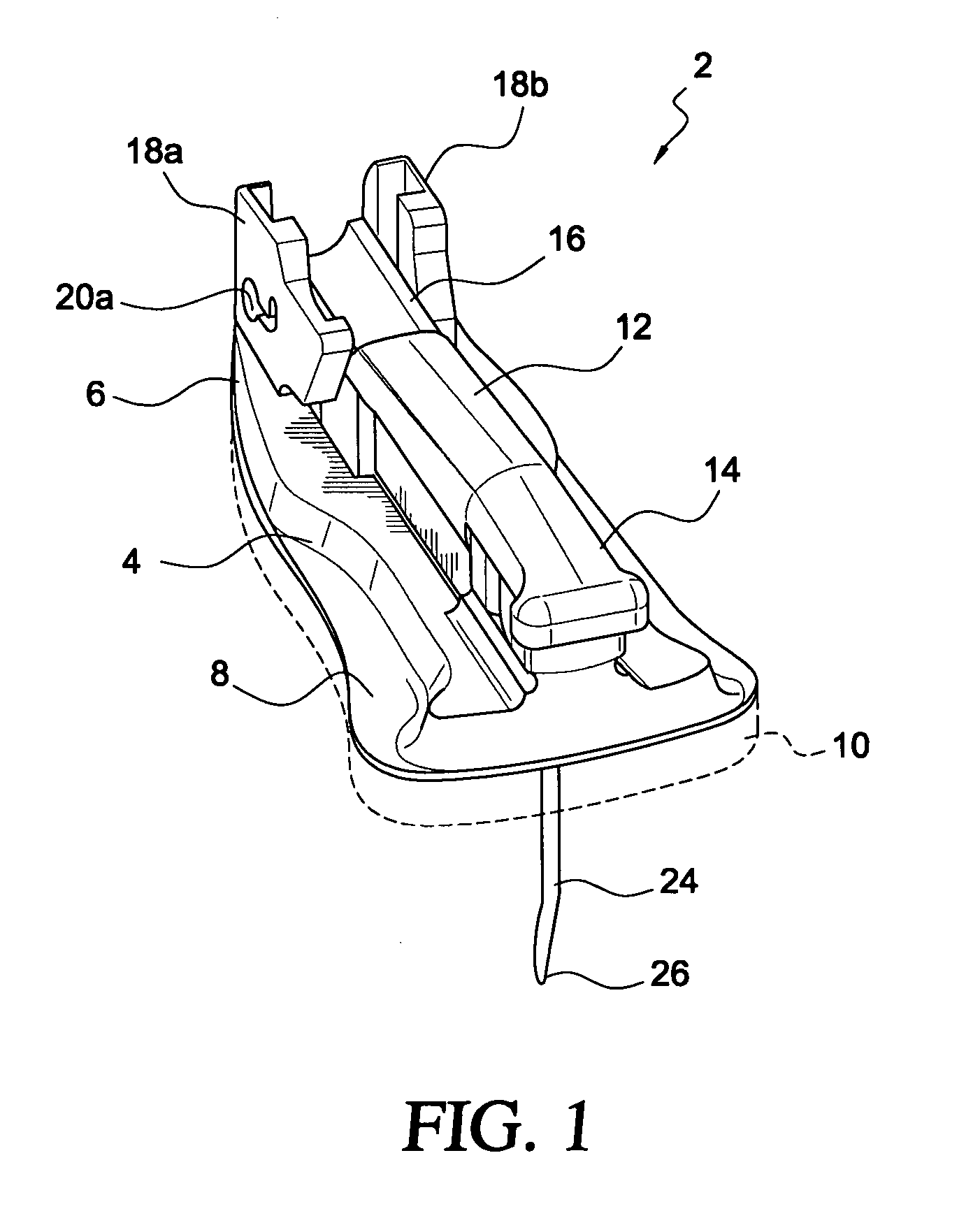

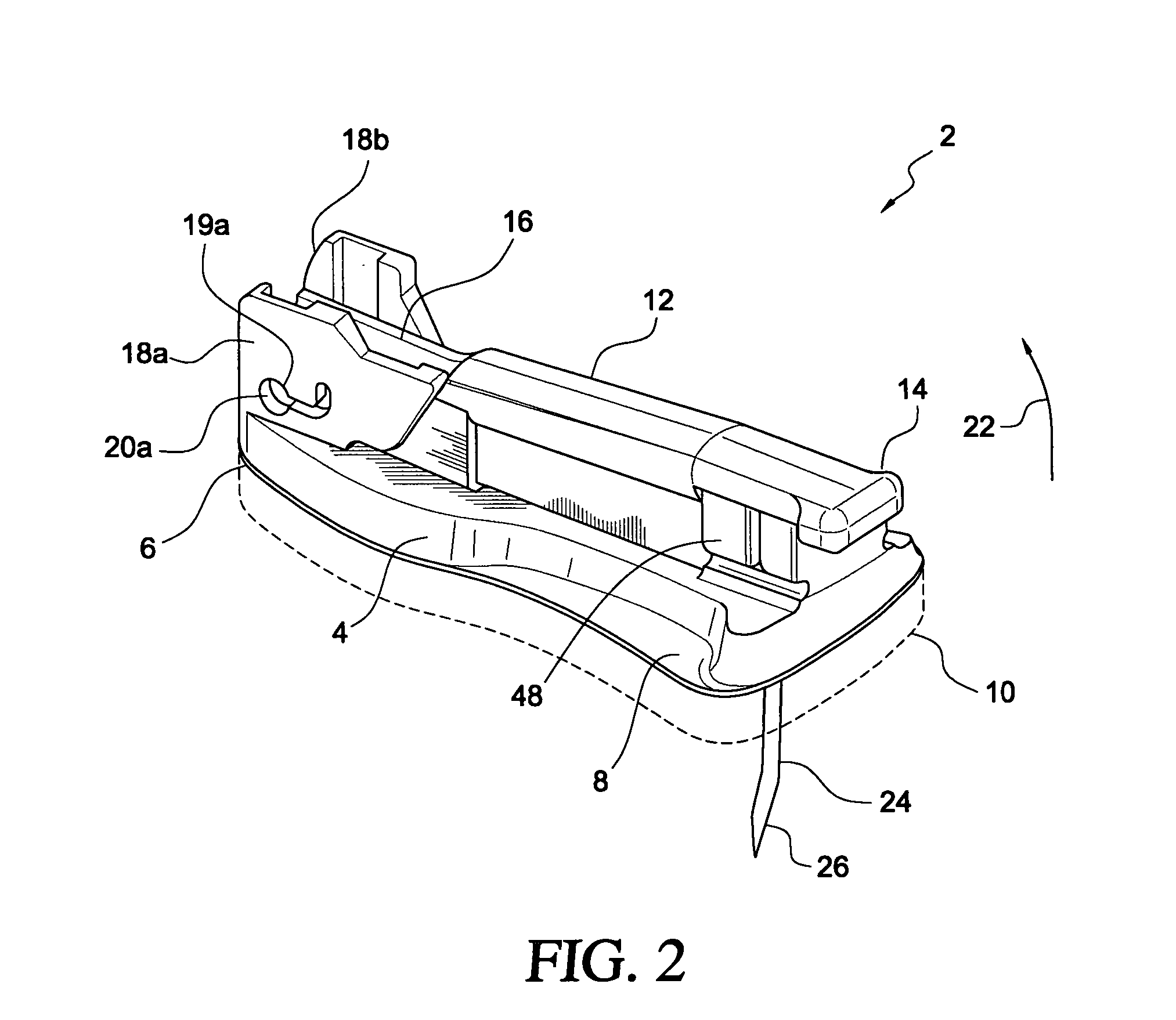

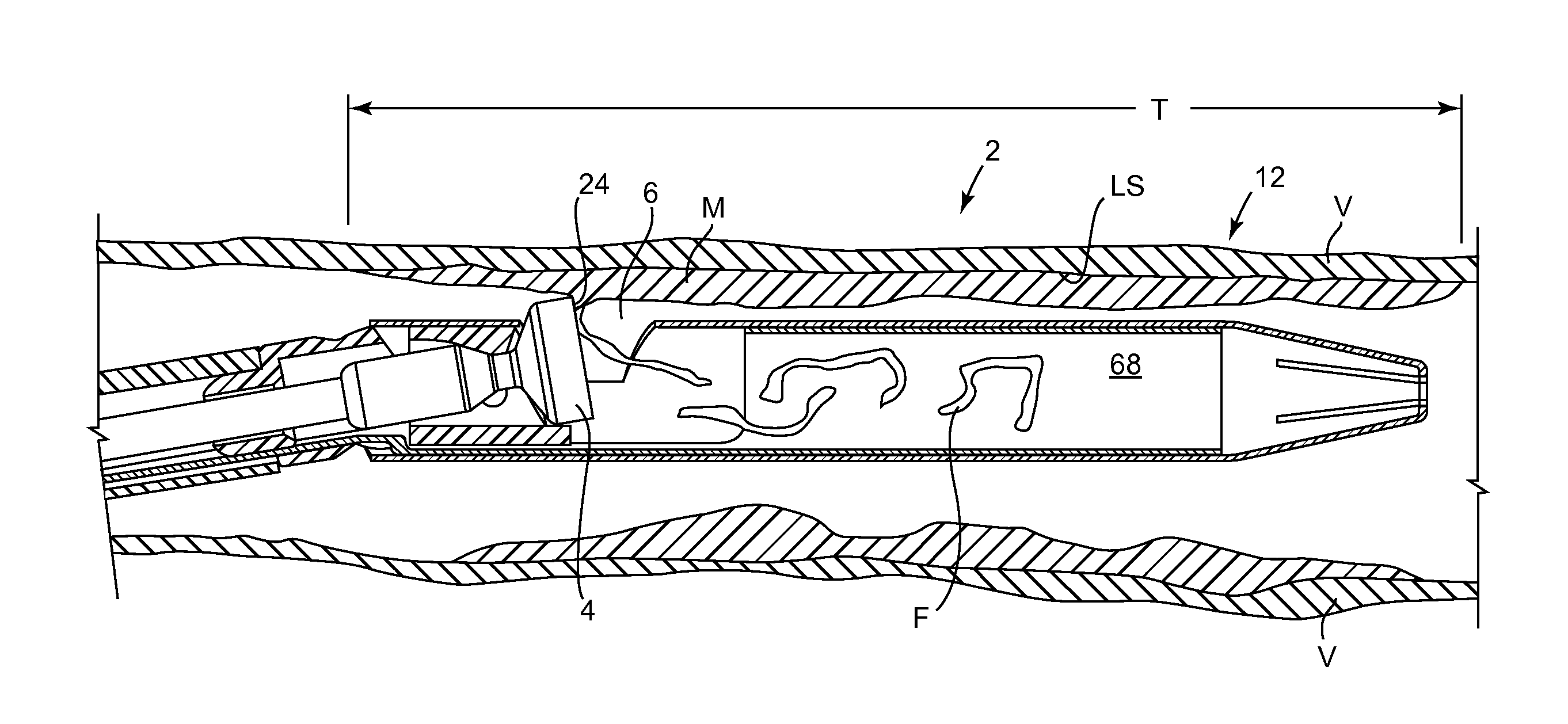

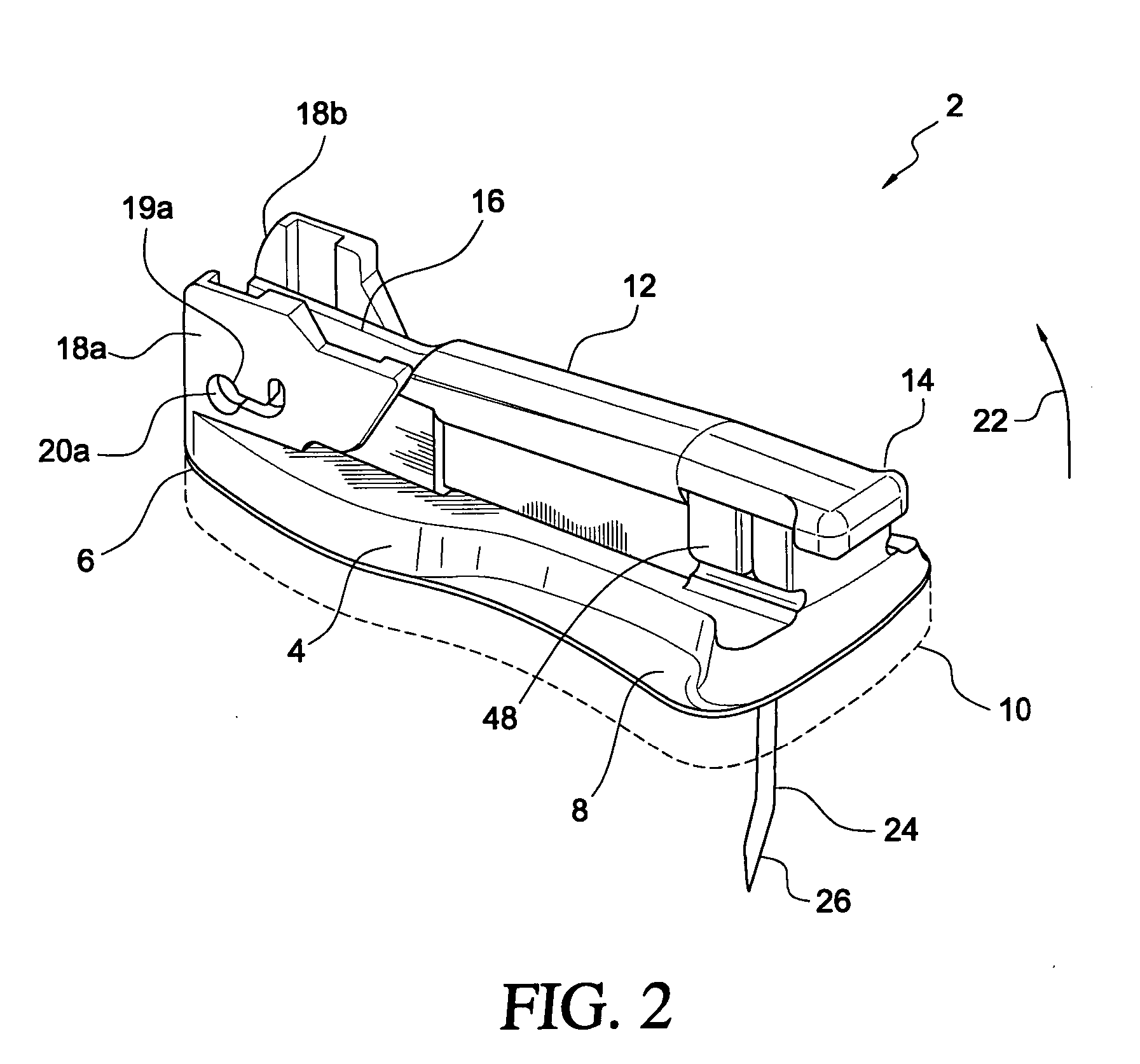

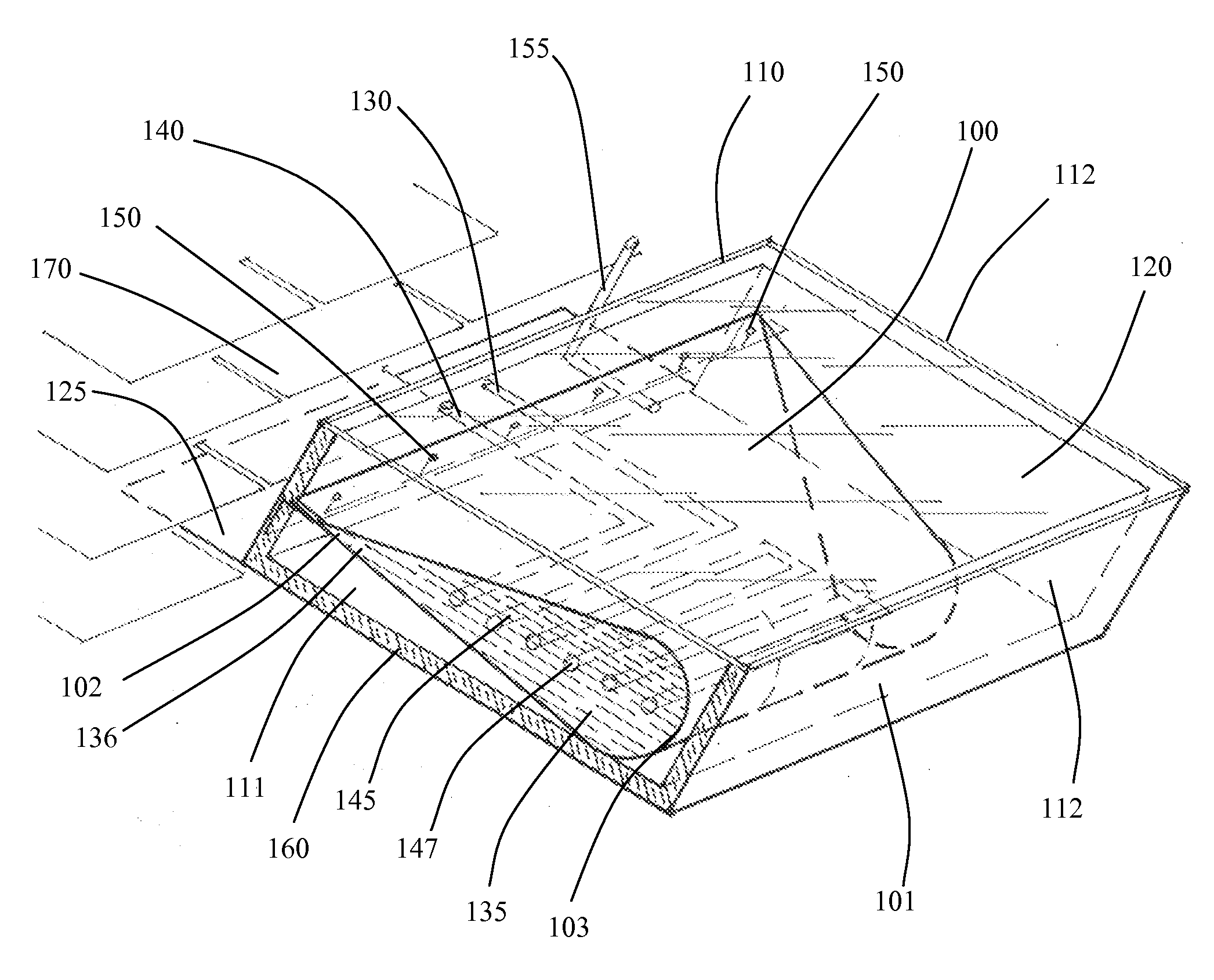

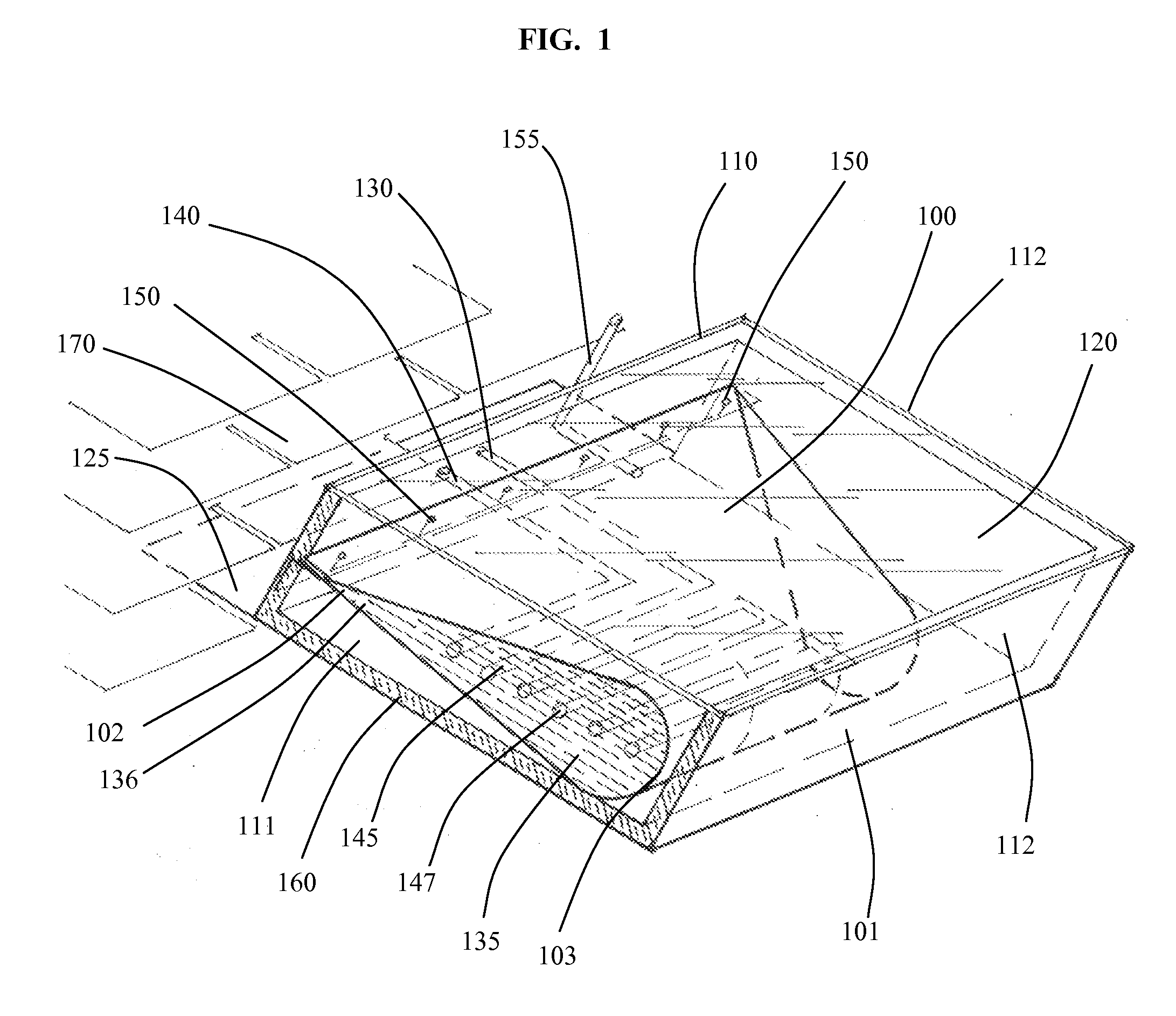

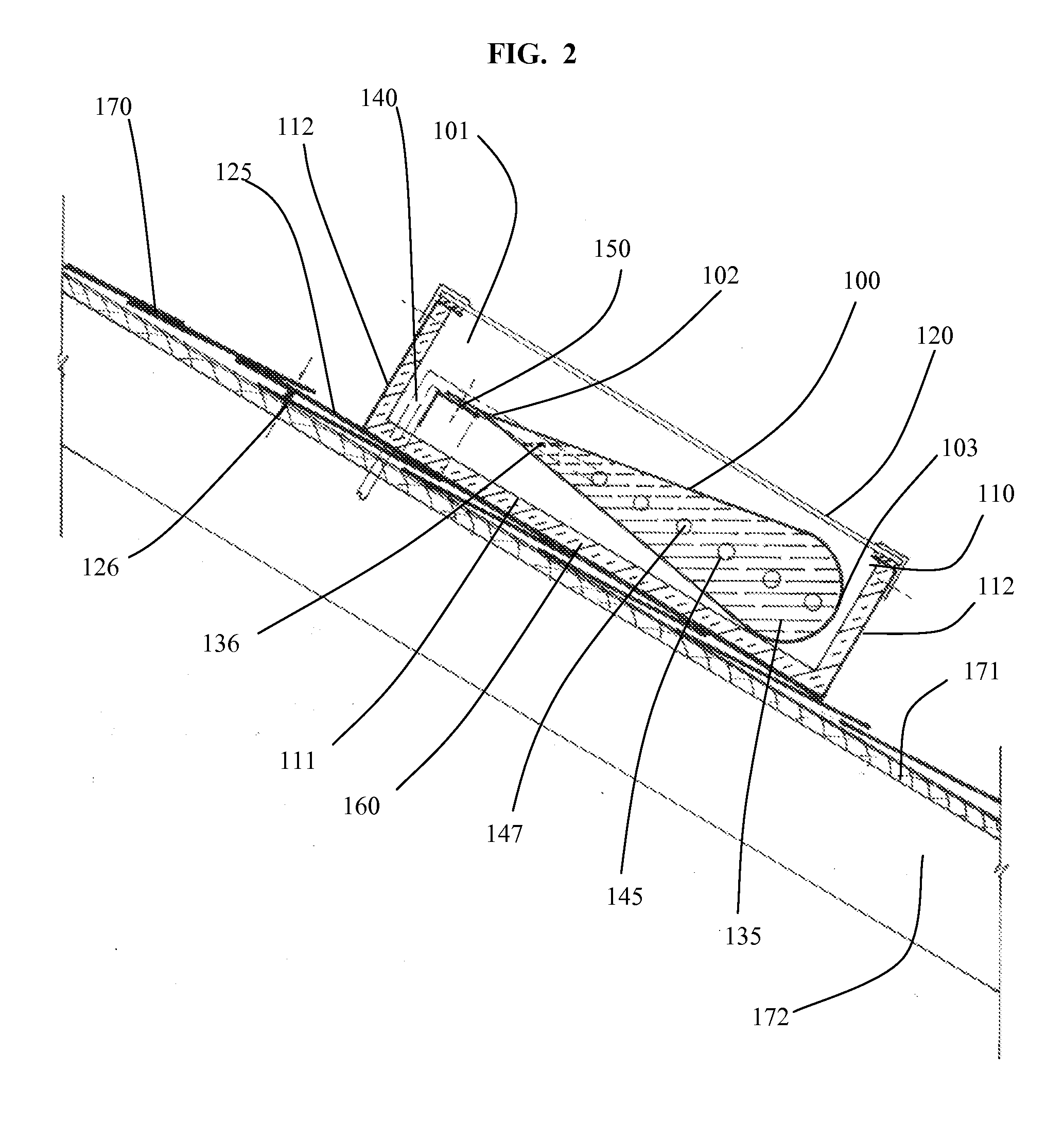

A portal access device that is adapted to provide long term access to a port implanted in a patient has two major components, an infuser assembly and a safety needle insertion device. The infuser assembly has an infuser housing that can be configured into a specific shape, for example a dome. A blunt cannula is attached to and extends downwardly from the underside of the infuser housing. Also connected to the infuser housing, preferably at a side thereof, is a tubing or catheter. The safety needle inserter assembly has a base having a proximal portion that is configured to form fit over the infuser housing. At the distal portion of the base uprights are provided so that a second end of an arm, to which first end a needle or a sharp cannula is connected, may be movably and hingedly connected to the base. The sharp cannula extends from the underside of the proximal end of the arm and passes through the base by way of a bore formed at the proximal portion of the base. The bore is defined between an opening at the underside of the base and an opening at the upper surface of the base. Locking mechanisms are provided at the base uprights and the distal end of the arm so that when the arm is moved away from the base, and as the distal end of the arm pivots about the uprights, the respective locking mechanisms provided at the arm and the base would coact to lock the arm in place, to thereby maintain the tip of the needle within the bore formed in the base. To use, the safety needle inserter is placed over the infuser assembly, with the sharp cannula extending through the infuser housing and axially mating with the blunt cannula of the infuser assembly, but with the tip of the sharp cannula protruding beyond the tip of the blunt cannula. The combined needle inserter / infuser assembly is pressed down onto the skin surface of the patient so that the combination sharp / blunt cannulas penetrate the patient and puncture the self-sealing septum of a portal reservoir implanted in the patient. Once the safety needle inserter is removed from the infuser assembly, with the infuser housing septum being self-sealing, a closed fluid communication path is established between the portal reservoir and a fluid store that may be connected to the catheter of the infuser assembly. Long term access of the implanted portal reservoir is thereby achieved.

Owner:SMITHS MEDICAL ASD INC

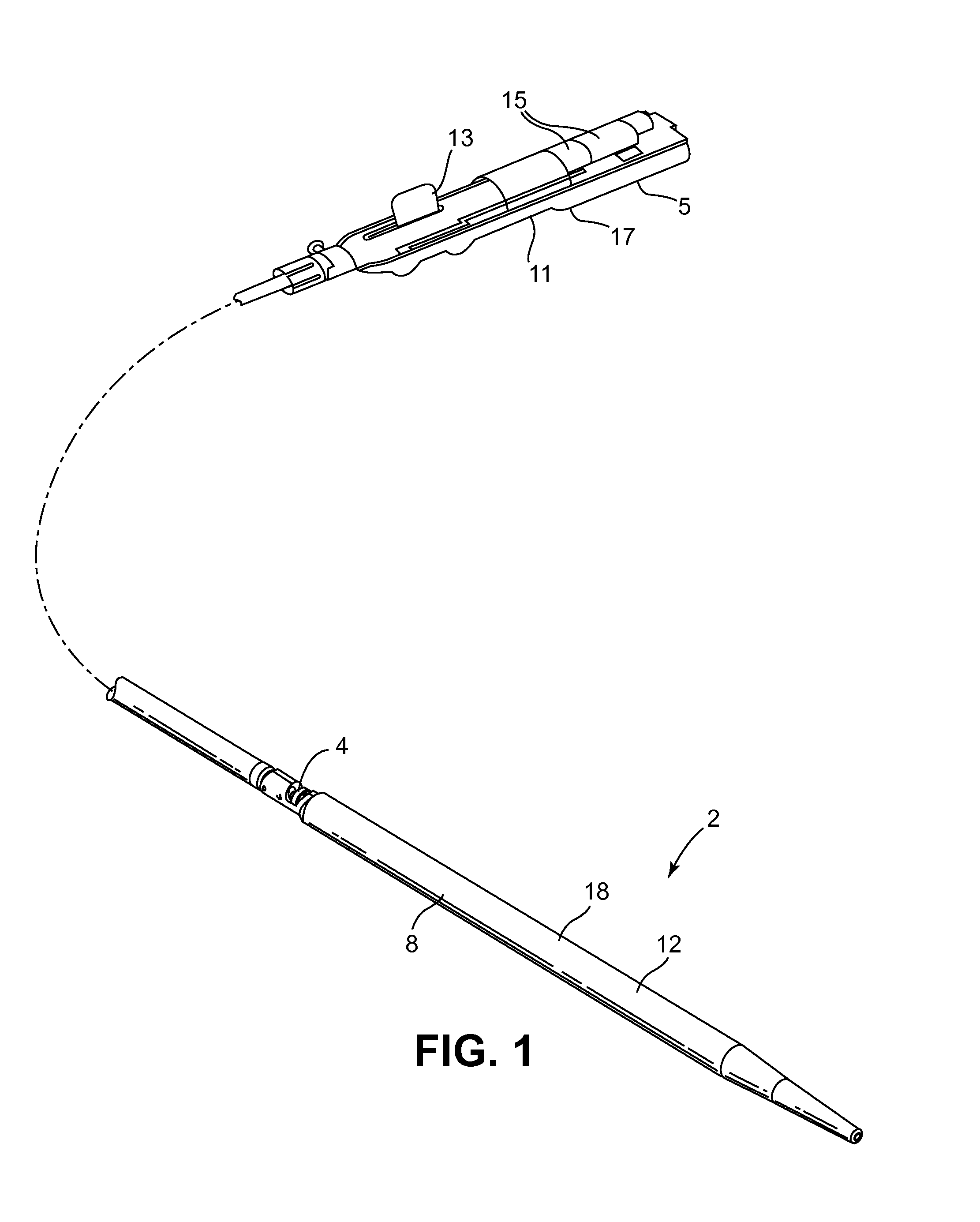

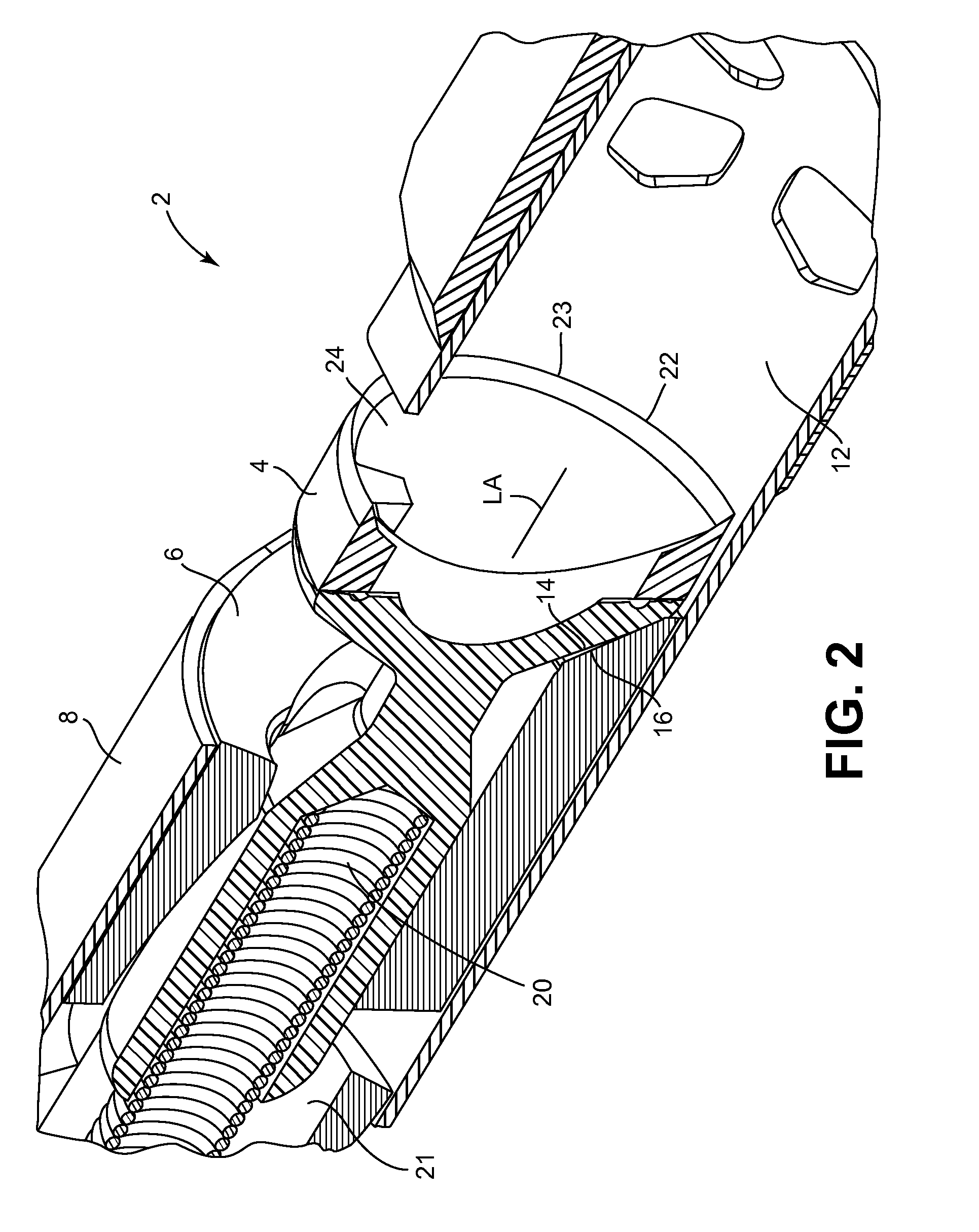

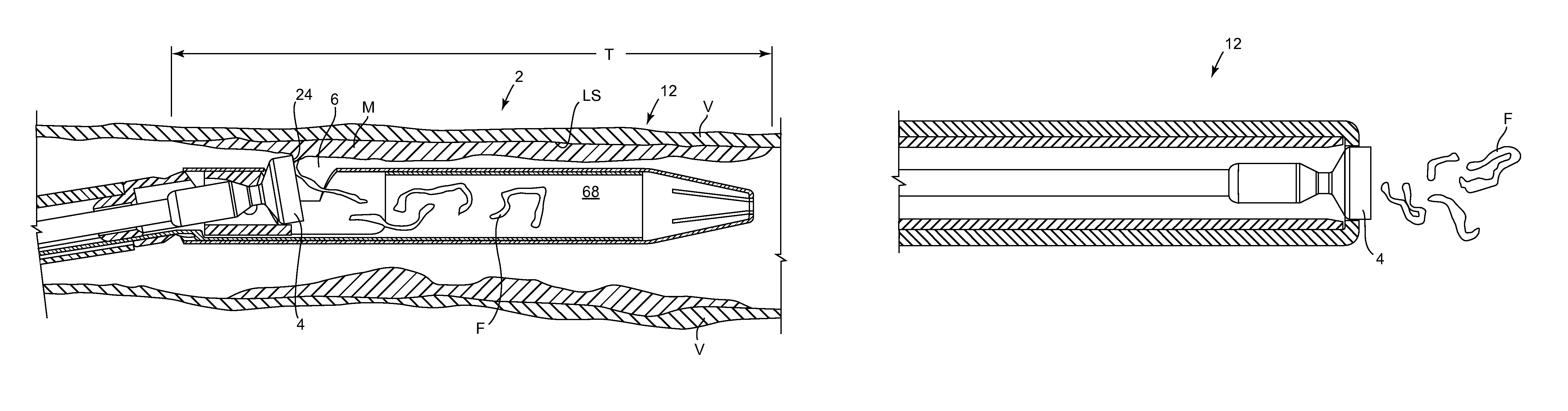

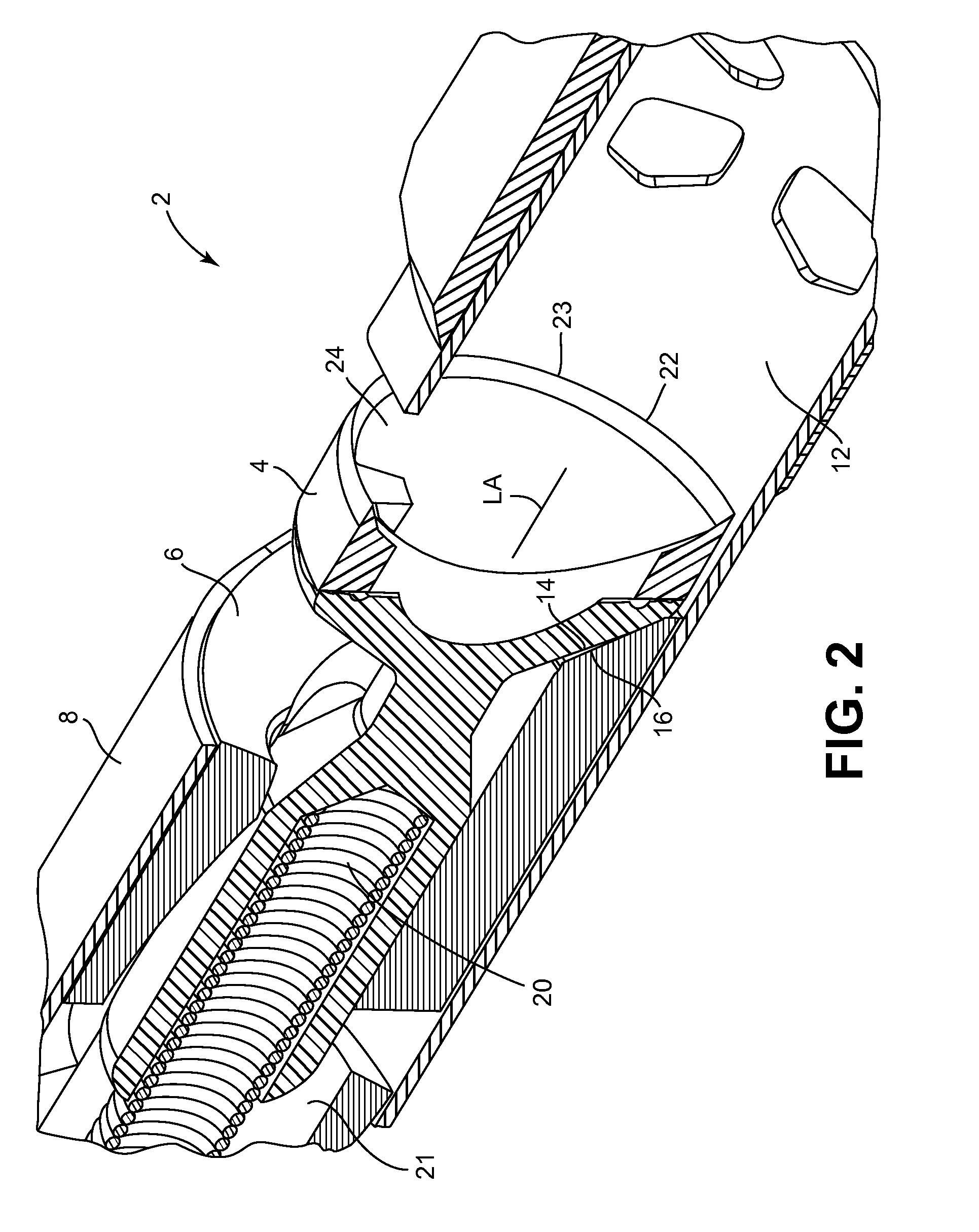

Easily cleaned atherectomy catheters and methods of use

ActiveUS20100292721A1Simple and fast and effectiveClean outCannulasExcision instrumentsAtherectomyTissue Collection

An atherectomy catheter is provided having a tissue collection chamber capable of being cleaned out in a simple, fast and effective way, and also provides methods of using said catheter to remove material from a blood vessel lumen. In one embodiment the tissue collection chamber has an expandable tip having a first closed position capable of retaining material in the chamber and having a second open position that may allow expulsion of material from the chamber. In a second embodiment the tissue collection chamber has a displaceable tip having a first closed position to retain material in the chamber and having a second open position to allow expulsion of material from the chamber.

Owner:TYCO HEALTHCARE GRP LP

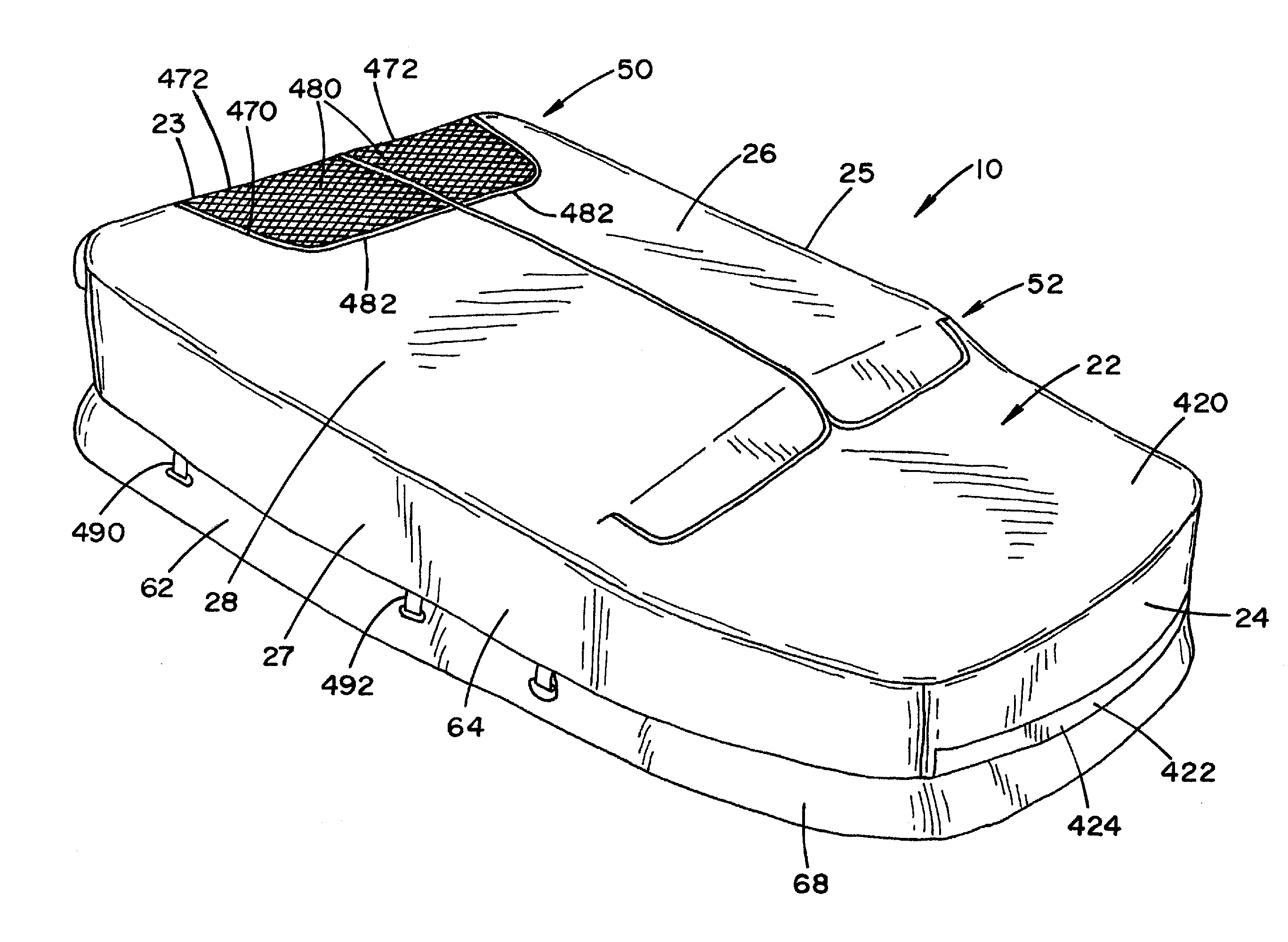

Removable sharps device for accessing a portal reservoir

ActiveUS20070149921A1Safe removalEasily gain accessMedical devicesInfusion needlesSkin surfaceLocking mechanism

A portal access device that is adapted to provide long term access to a port implanted in a patient has two major components, an infuser assembly and a safety needle insertion device. The infuser assembly has an infuser housing that can be configured into a specific shape, for example a dome. A blunt cannula is attached to and extends downwardly from the underside of the infuser housing. Also connected to the infuser housing, preferably at a side thereof, is a tubing or catheter. The safety needle inserter assembly has a base having a proximal portion that is configured to form fit over the infuser housing. At the distal portion of the base uprights are provided so that a second end of an arm, to which first end a needle or a sharp cannula is connected, may be movably and hingedly connected to the base. The sharp cannula extends from the underside of the proximal end of the arm and passes through the base by way of a bore formed at the proximal portion of the base. The bore is defined between an opening at the underside of the base and an opening at the upper surface of the base. Locking mechanisms are provided at the base uprights and the distal end of the arm so that when the arm is moved away from the base, and as the distal end of the arm pivots about the uprights, the respective locking mechanisms provided at the arm and the base would coact to lock the arm in place, to thereby maintain the tip of the needle within the bore formed in the base. To use, the safety needle inserter is placed over the infuser assembly, with the sharp cannula extending through the infuser housing and axially mating with the blunt cannula of the infuser assembly, but with the tip of the sharp cannula protruding beyond the tip of the blunt cannula. The combined needle inserter / infuser assembly is pressed down onto the skin surface of the patient so that the combination sharp / blunt cannulas penetrate the patient and puncture the self-sealing septum of a portal reservoir implanted in the patient. Once the safety needle inserter is removed from the infuser assembly, with the infuser housing septum being self-sealing, a closed fluid communication path is established between the portal reservoir and a fluid store that may be connected to the catheter of the infuser assembly. Long term access of the implanted portal reservoir is thereby achieved.

Owner:SMITHS MEDICAL ASD INC

Pool cleaner with open-ended pin supported flapper valve

InactiveUS6298513B1Reduce frictional resistanceClean outGymnasiumSwimming poolsMarine engineeringFlapper

A domestic automatic swimming pool cleaner which randomly travels about and cleans the walls and bottom surfaces of a swimming pool includes two parallel or non-parallel impact tubes, the top ends of which are connected to a flexible suction hose which in turn is connected to the suction side of the pool's filter pump. The bottom ends of the tubes are served intermittent shots of water by a hinged self-starting flapper valve with an unrestricted upstream opening in the cleaner's pool surface contacting head. By the action of the valve alternately delivering pool water to the two tubes, kinetic forces are generated which move the automatic pool cleaner about the pool.

Owner:HAYWARD IND INC

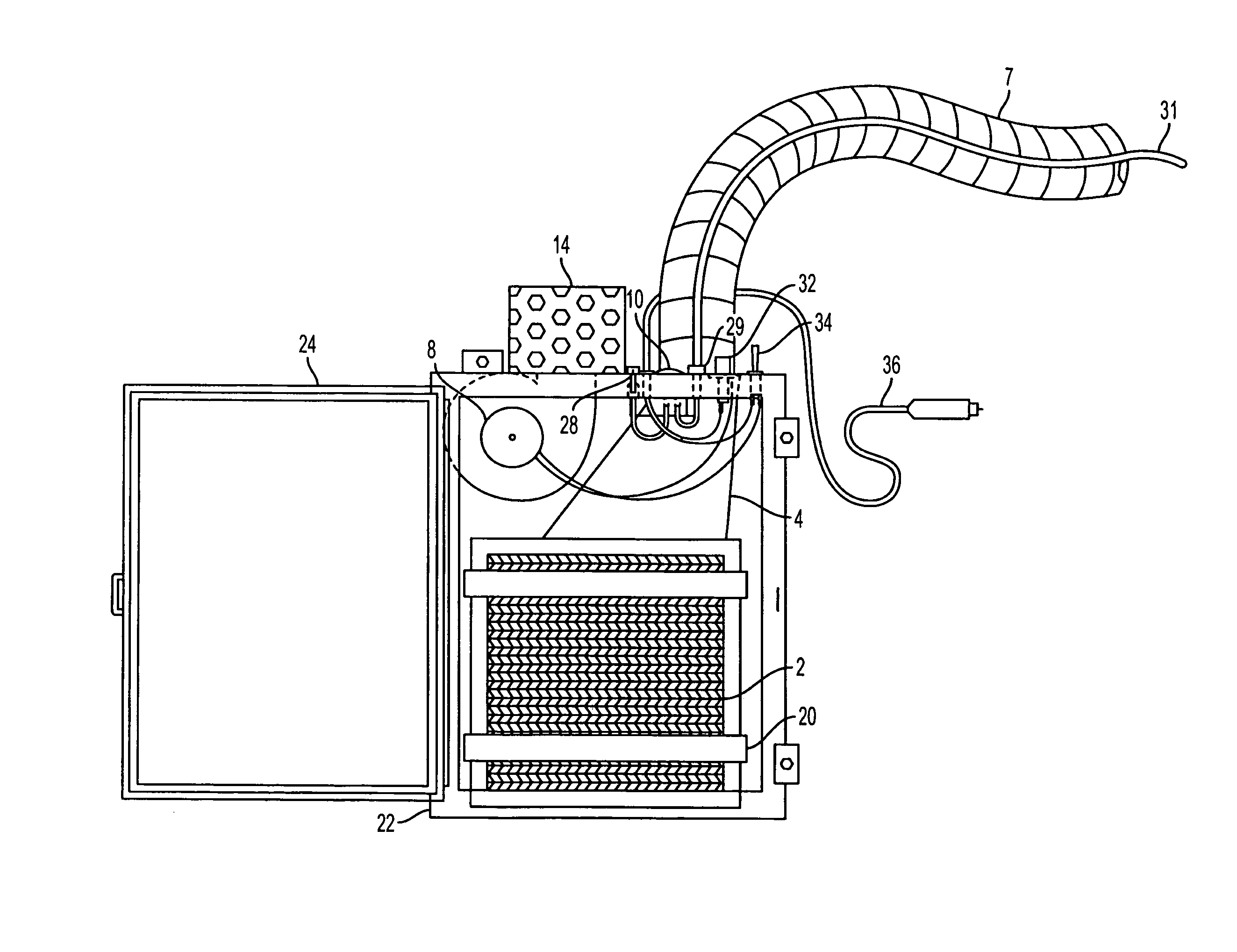

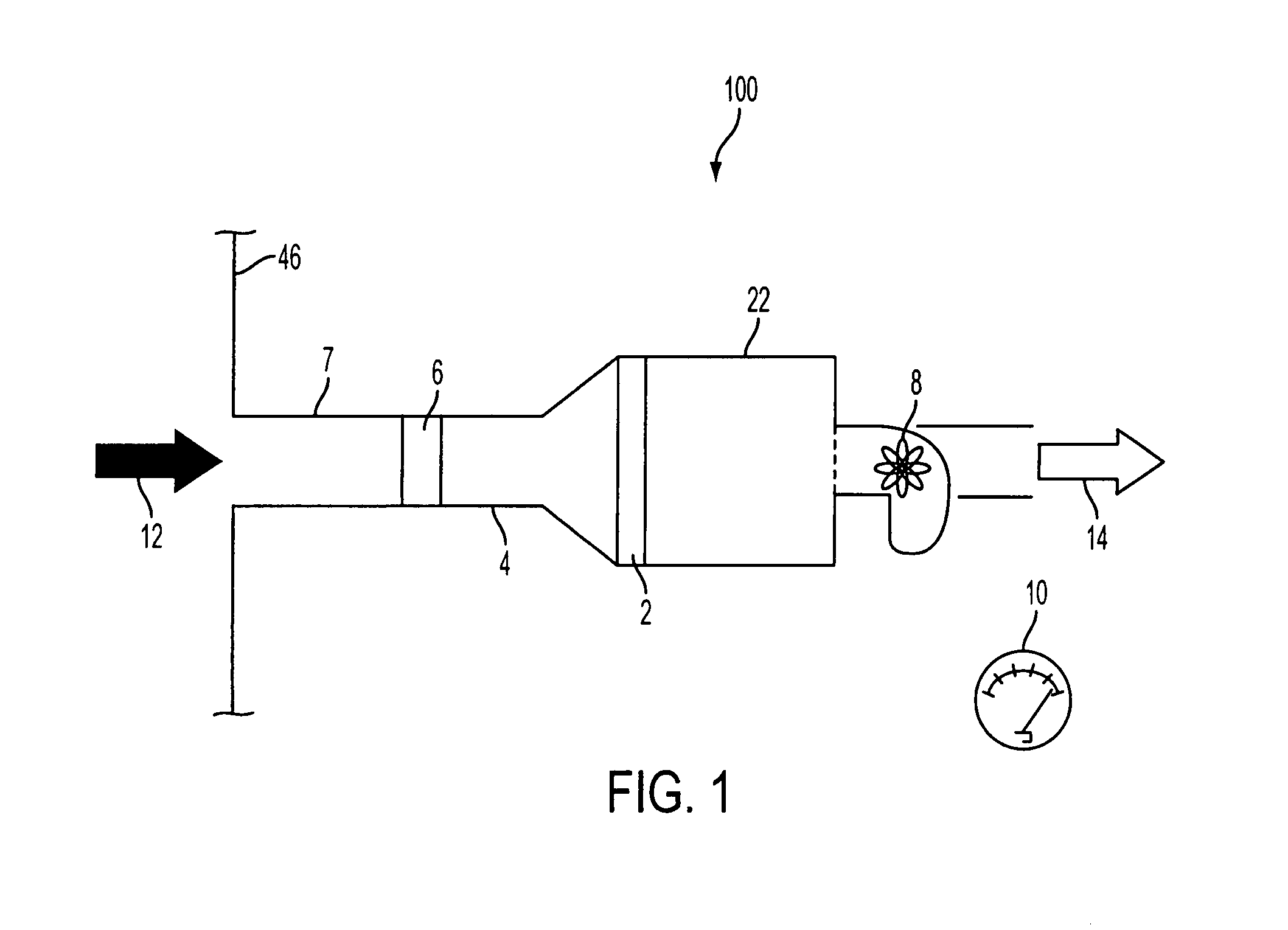

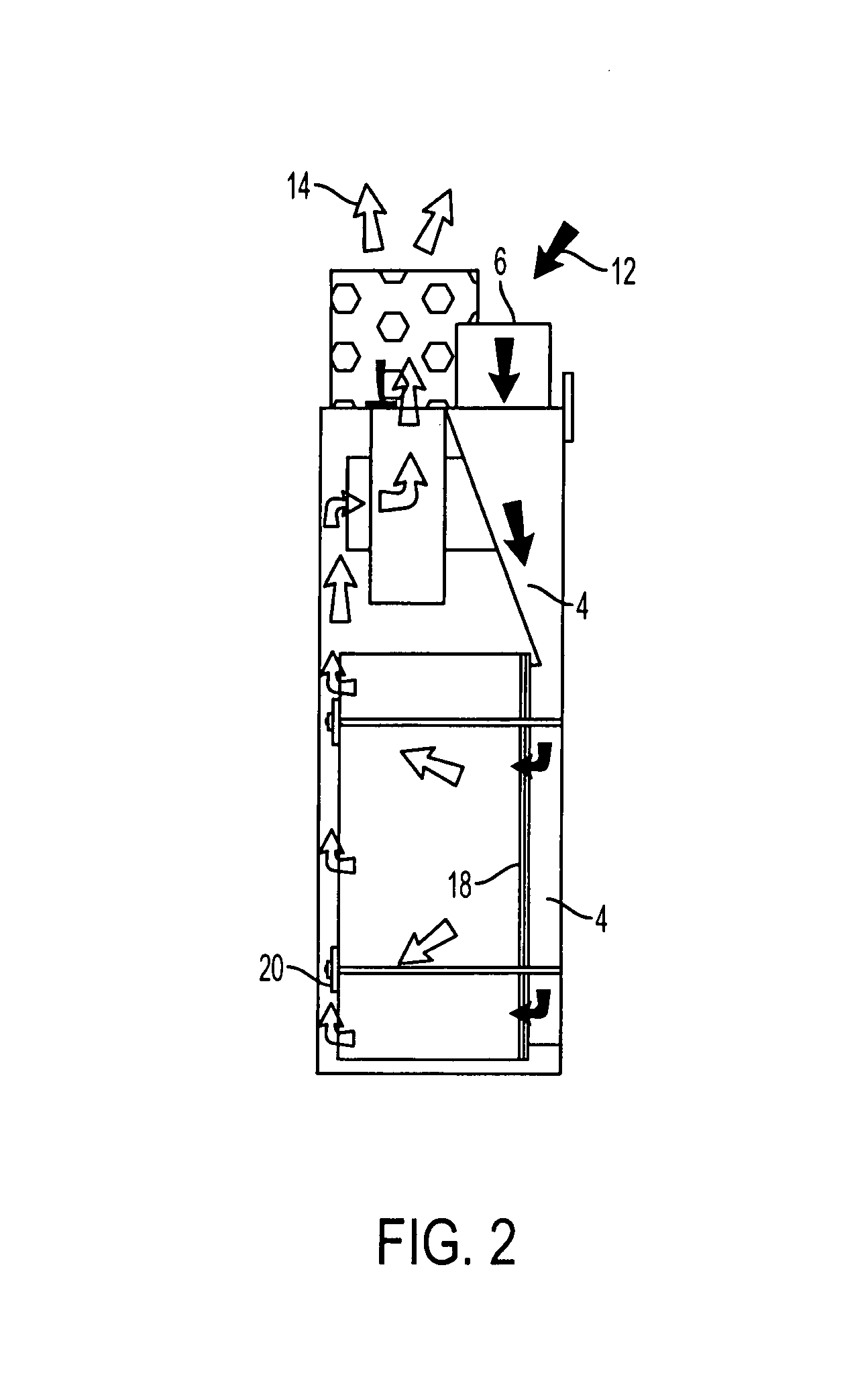

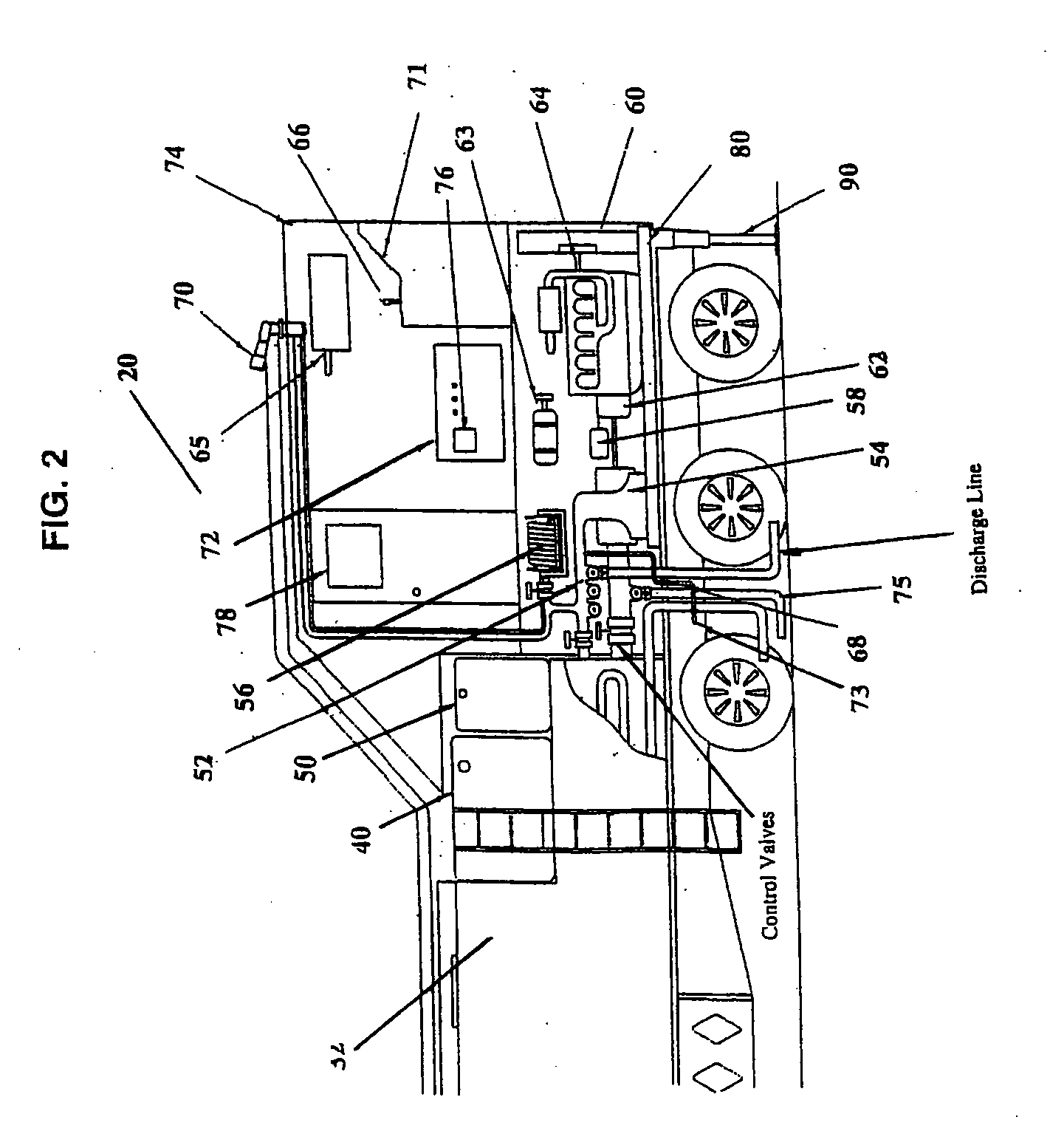

Air filtration and positive pressurization system for vehicles in environmentally adverse conditions

A system and method for providing filtered and pressurized air into a vehicle cab, enclosure or other interior enclosed environment is described, in which a filtered positive pressure air unit comprises a sealed box, a HEPA filter, a blower, a magnahelic, power source and ductwork. Dirty air is drawn by the blower through the hose and ductwork to the HEPA filter where a certain percentage of impurities of a certain size or larger are removed. Clean air is discharged at a sufficiently high rate to create a positive pressure inside the interior enclosed environment, keeping clean air in, and dirty air out.

Owner:NORTHSTAR DEMOLITION & REMEDIATION LP

Easily cleaned atherectomy catheters and methods of use

ActiveUS8192452B2Simple and fast and effectiveClean outCannulasExcision instrumentsAtherectomyTissue Collection

An atherectomy catheter is provided having a tissue collection chamber capable of being cleaned out in a simple, fast and effective way, and also provides methods of using said catheter to remove material from a blood vessel lumen. In one embodiment the tissue collection chamber has an expandable tip having a first closed position capable of retaining material in the chamber and having a second open position that may allow expulsion of material from the chamber. In a second embodiment the tissue collection chamber has a displaceable tip having a first closed position to retain material in the chamber and having a second open position to allow expulsion of material from the chamber.

Owner:TYCO HEALTHCARE GRP LP

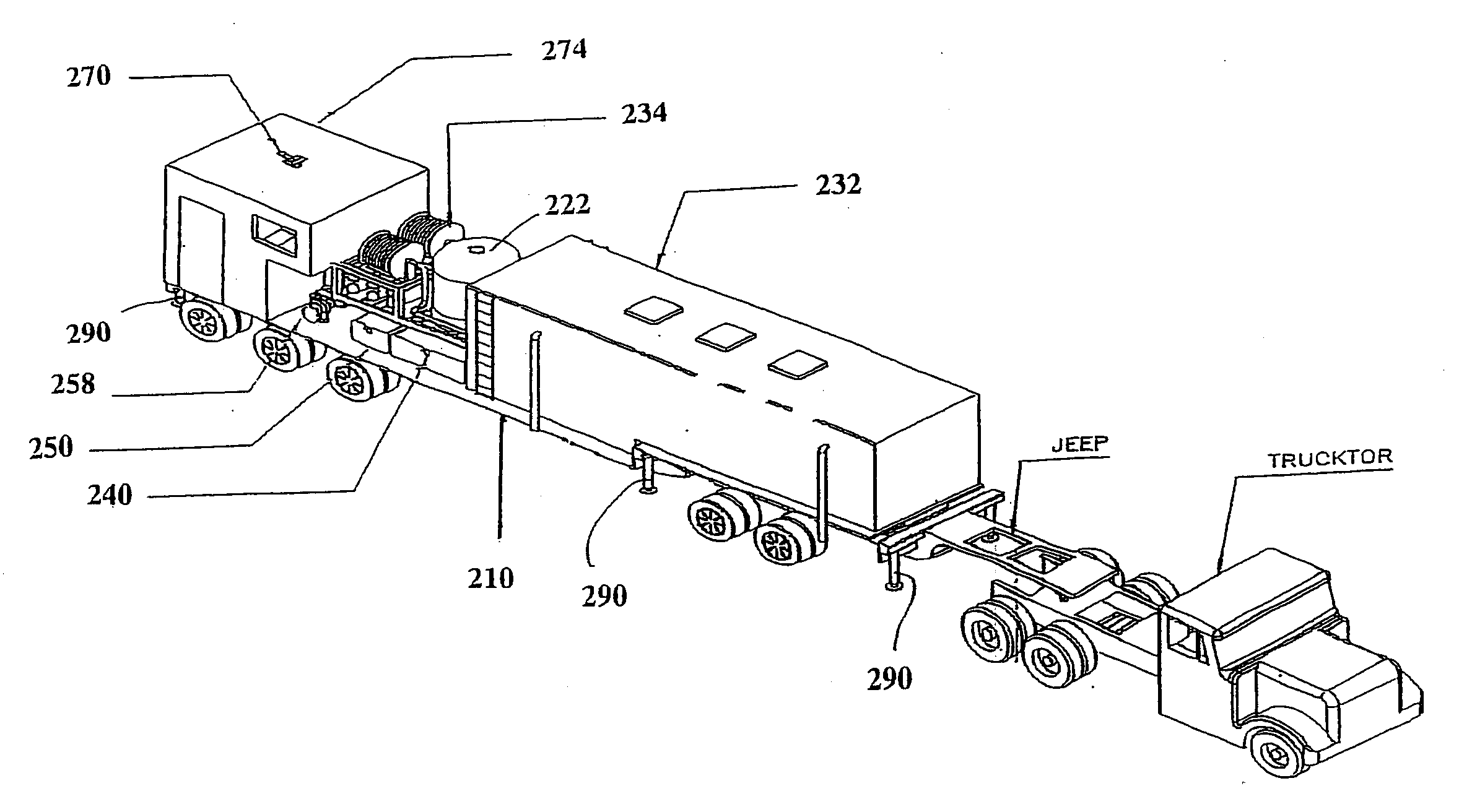

Fluid supply unit

InactiveUS20100038100A1Improve load stabilityDecrease soil compression and impactionDomestic plumbingFire rescueEngineeringFire control

A fully moveable and totally contained fluid supply unit useful in supplying fluid such as water to a site in need of such fluid for drilling, fire control, clean up, and the like is provided comprising a skid or a trailer having mounted thereon a fluid reservoir for holding the fluid; a fluid pumping system for pumping fluids to said site; and an engine for providing prime power to operate the fluid pumping system.

Owner:SCHUETZLE LORNE

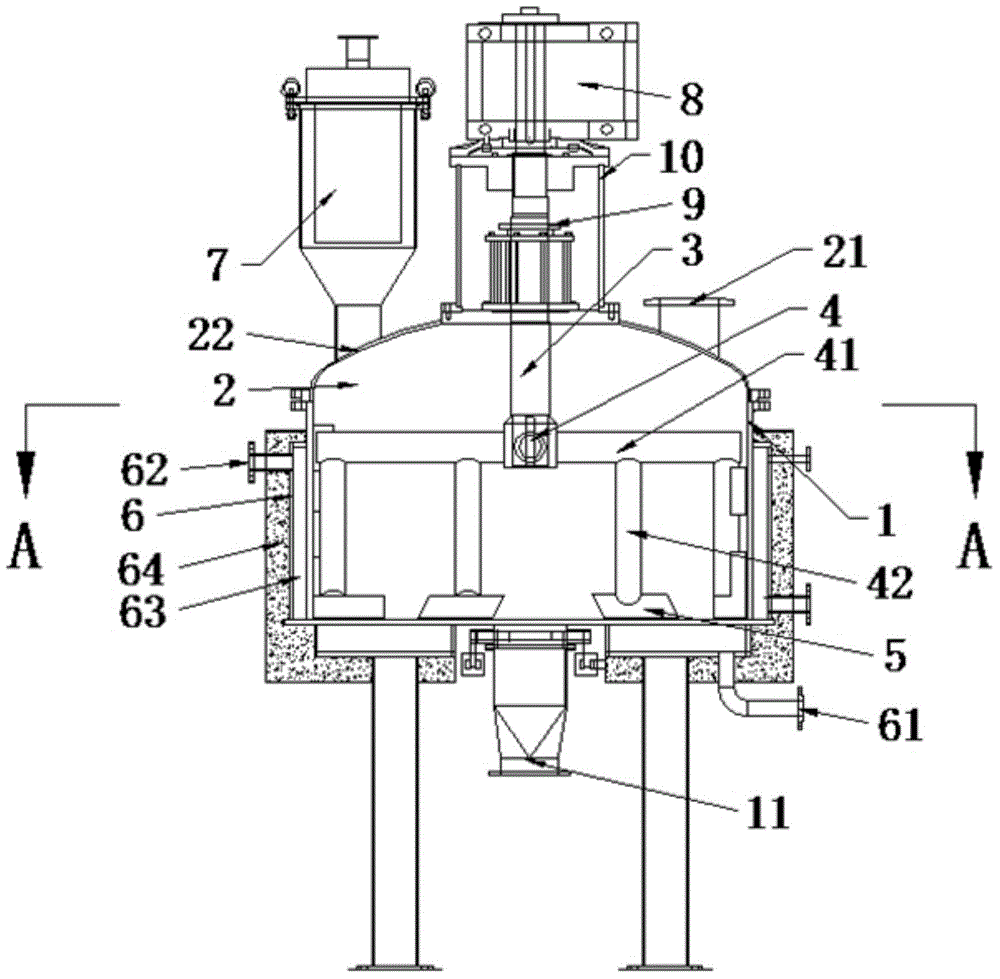

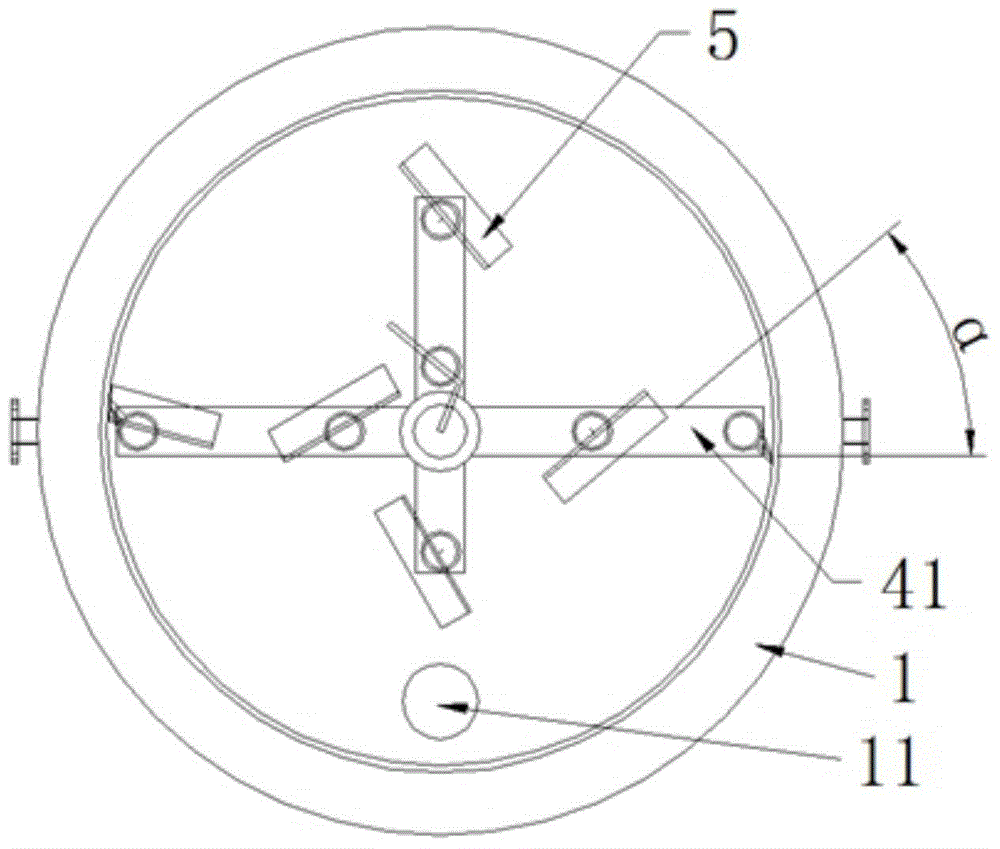

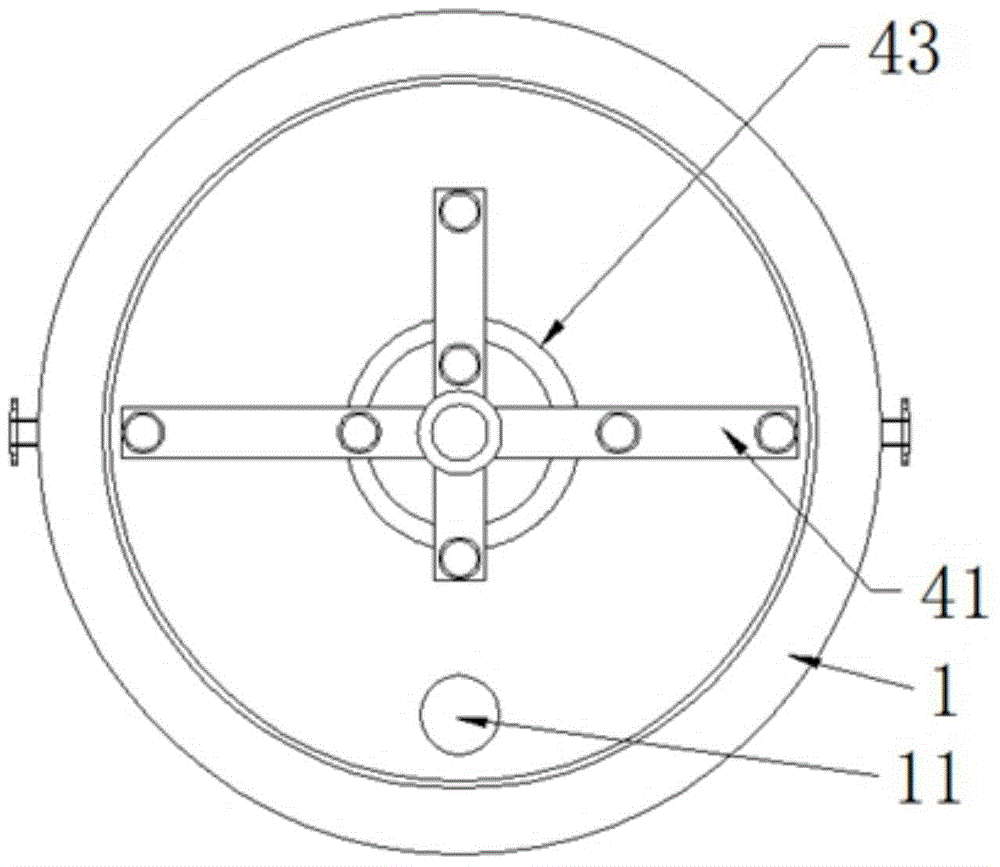

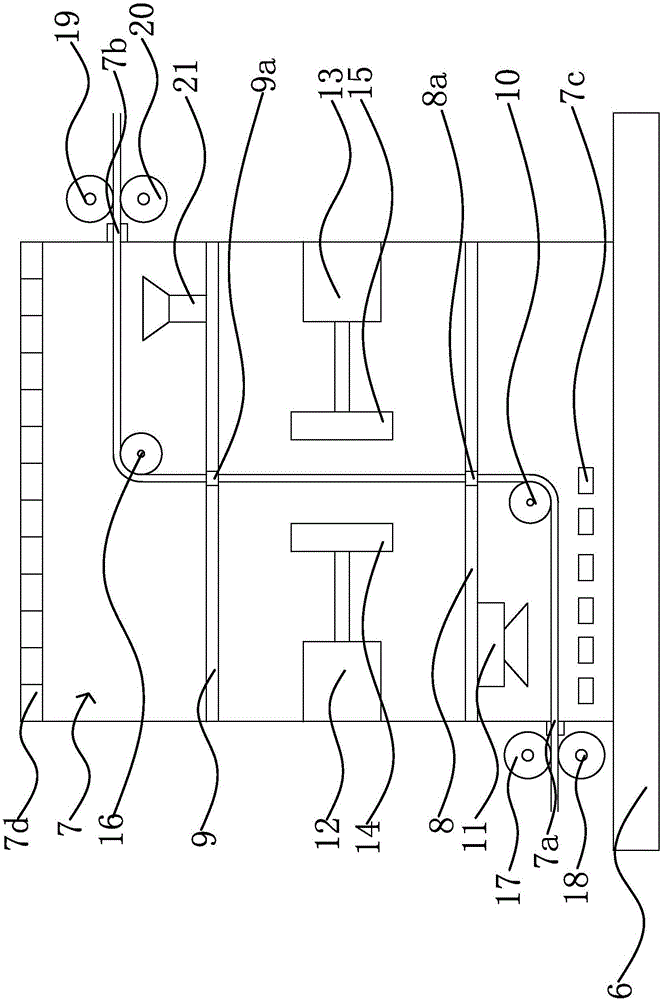

Stirring vacuum drying machine of scraping plate

InactiveCN104359292AEasy to launchGood adhesionDrying chambers/containersDrying machines with non-progressive movementsEngineeringPulp and paper industry

The invention relates to a stirring vacuum drying machine of a scraping plate. The stirring vacuum drying machine comprises an upright cylinder, a stirring device, an evacuating device and a heating device, wherein the upright cylinder is of a separated structure and comprises a cylinder body and a cylinder cover, wherein the cylinder body is provided with a closed end, an opened end and a side wall; a material outlet is formed in the place, close to the side wall, on the closed end; the cylinder cover covers the opened end; a material inlet and an evacuating opening are formed in the cylinder cover; the stirring device is formed by sequentially connecting a driving mechanism, a main shaft, a stirring frame and the scraping plate; the main shaft penetrates through the cylinder cover to extend into the cylinder body; the stirring frame is arranged at the lower end of the main shaft; the scraping plate is arranged at the lower end of the stirring frame; the evacuating device is arranged at the evacuating opening; the heating device wraps the cylinder body. According to the stirring vacuum drying machine, due to the fact that the material outlet is directly formed in the closed end of the cylinder body and is close to the side wall, the scraping plate just pushes dried materials to the place, close to the side wall, of the closed end, and the materials move along the scraping plate, the materials are very easily pushed out of the material outlet, and the stirring vacuum drying machine is simple, feasible and quick in operation; due to the fact that the materials are not stuck to the inside of the cylinder body, the materials are completely discharged.

Owner:CHANGZHOU YIBU DRYING EQUIP

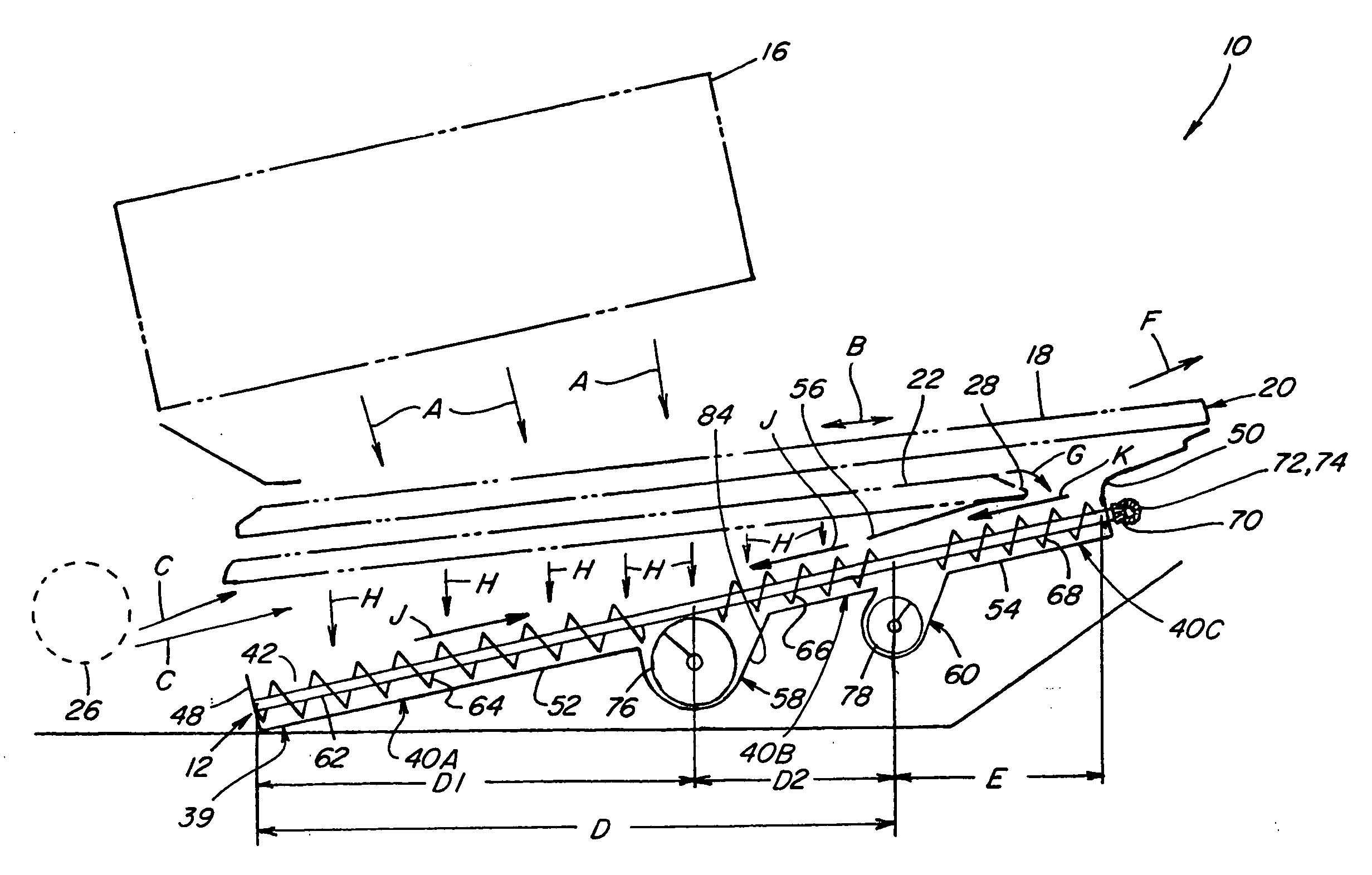

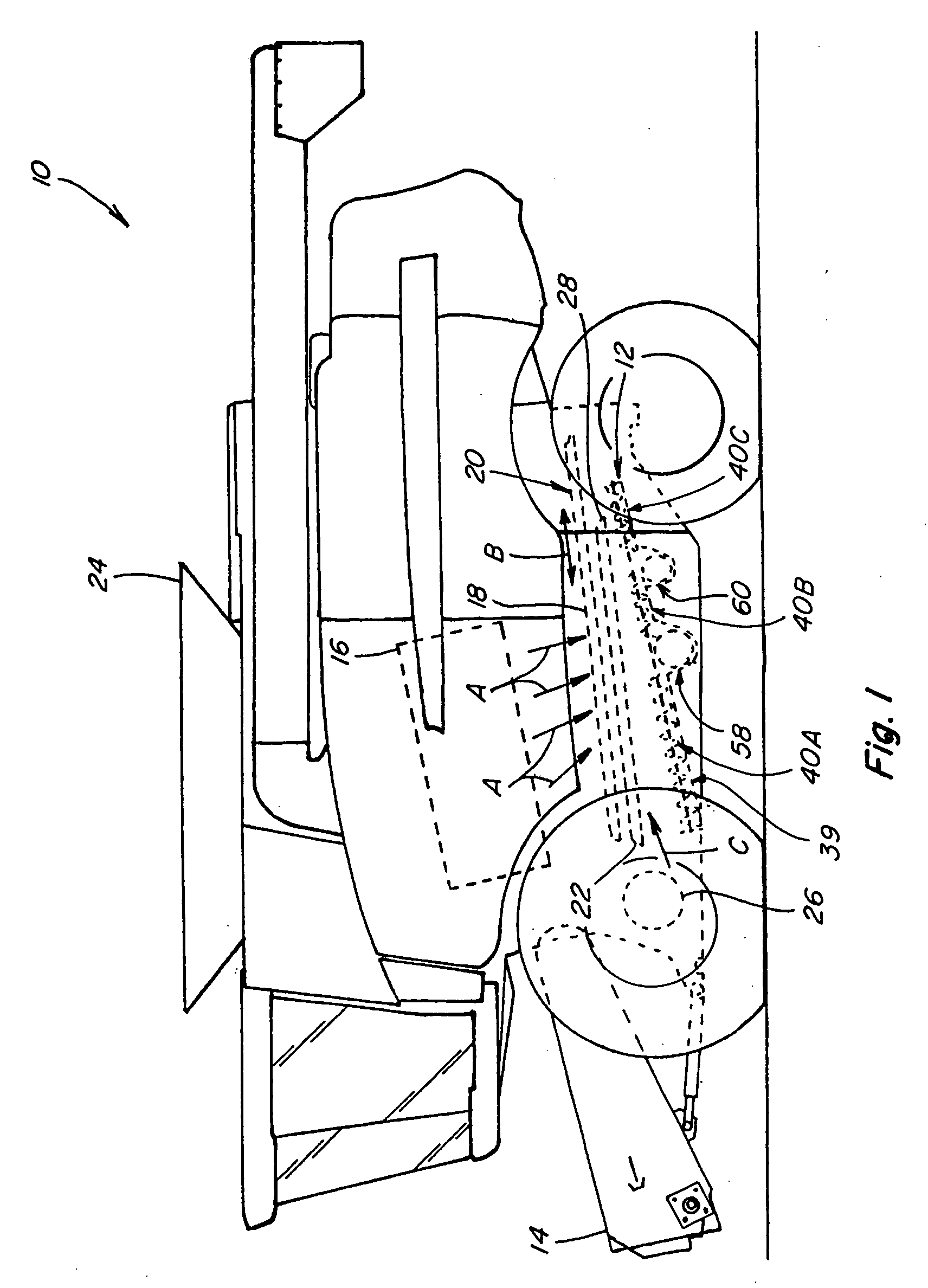

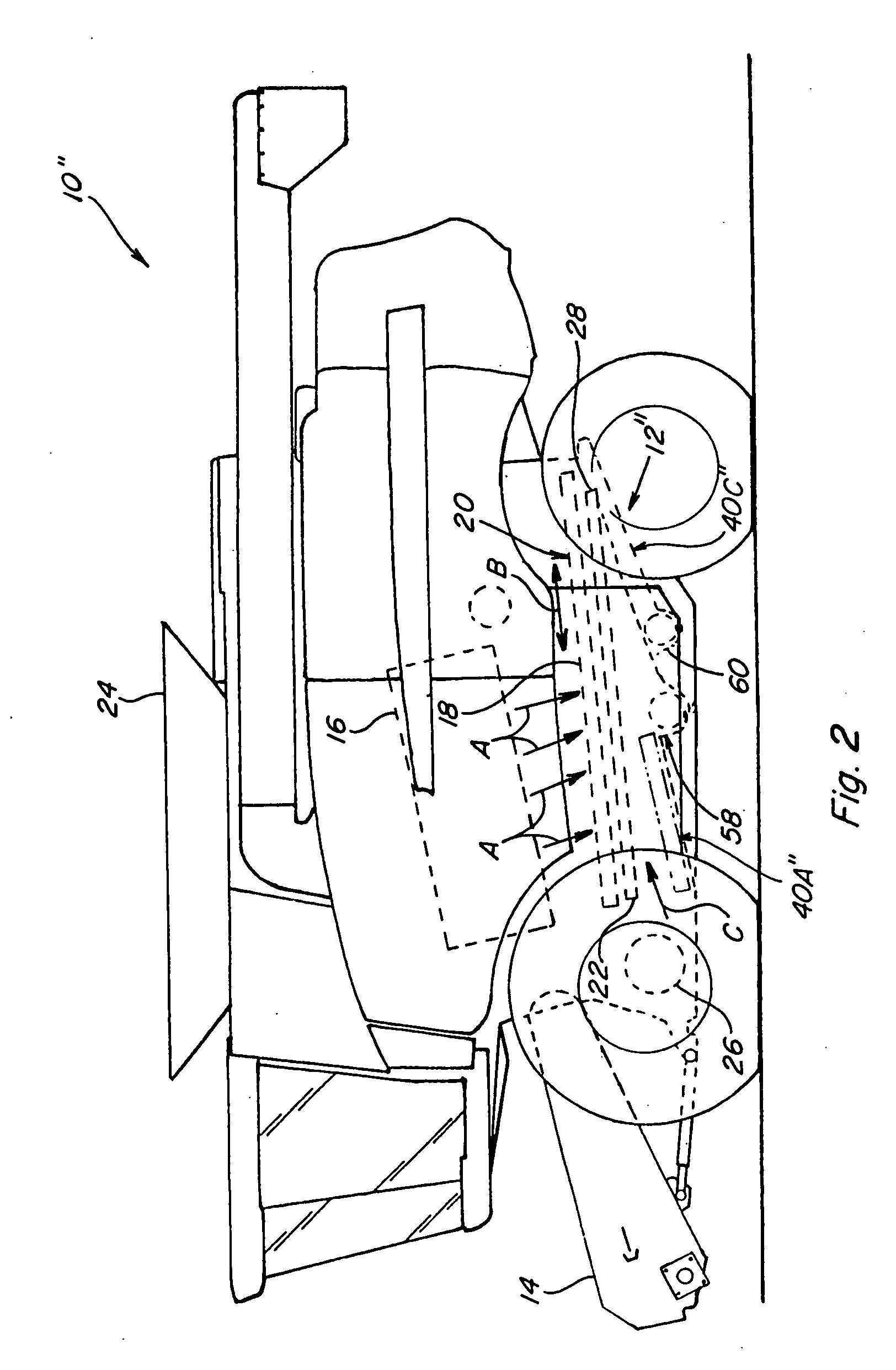

Auger trough clean-out door

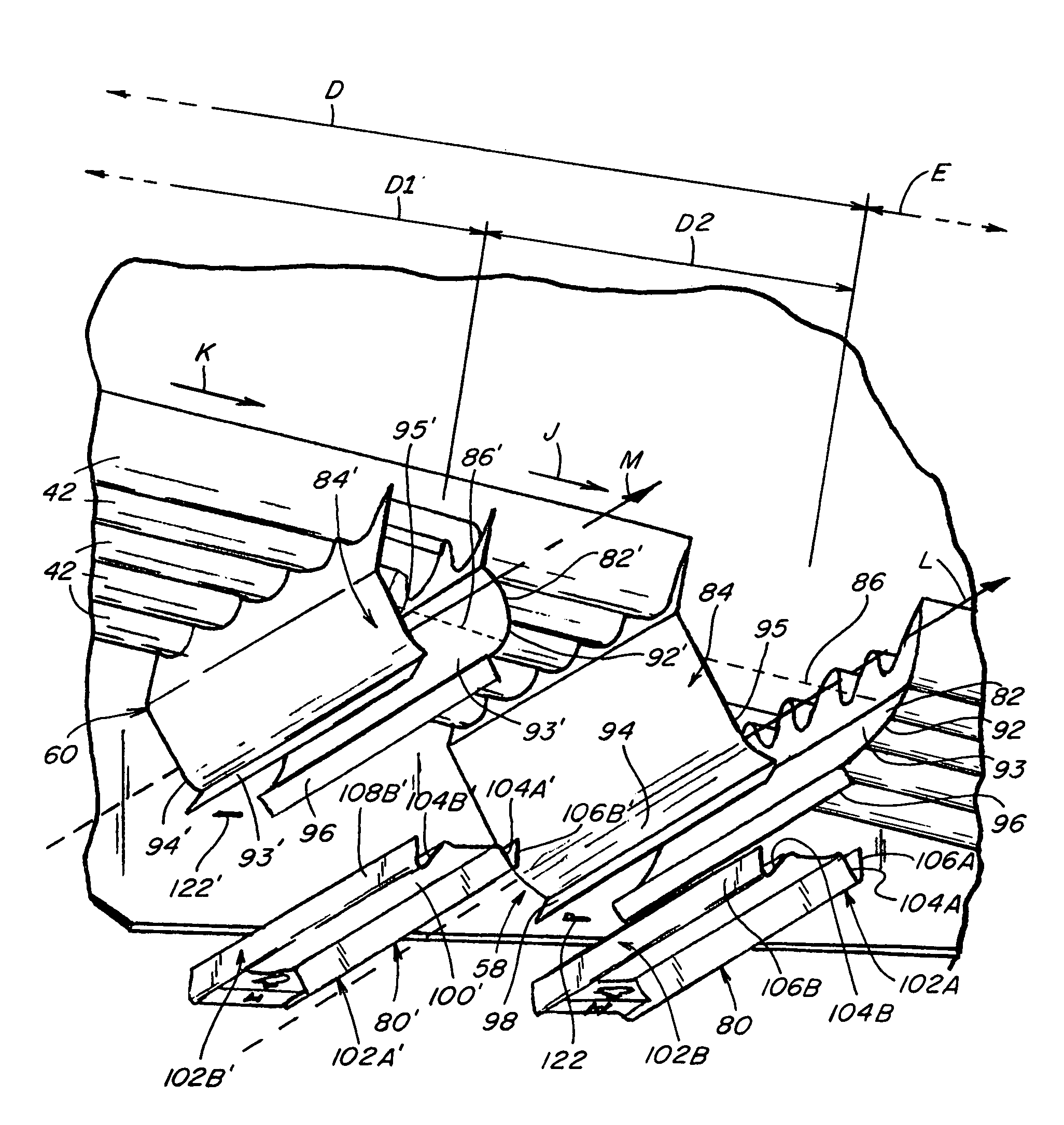

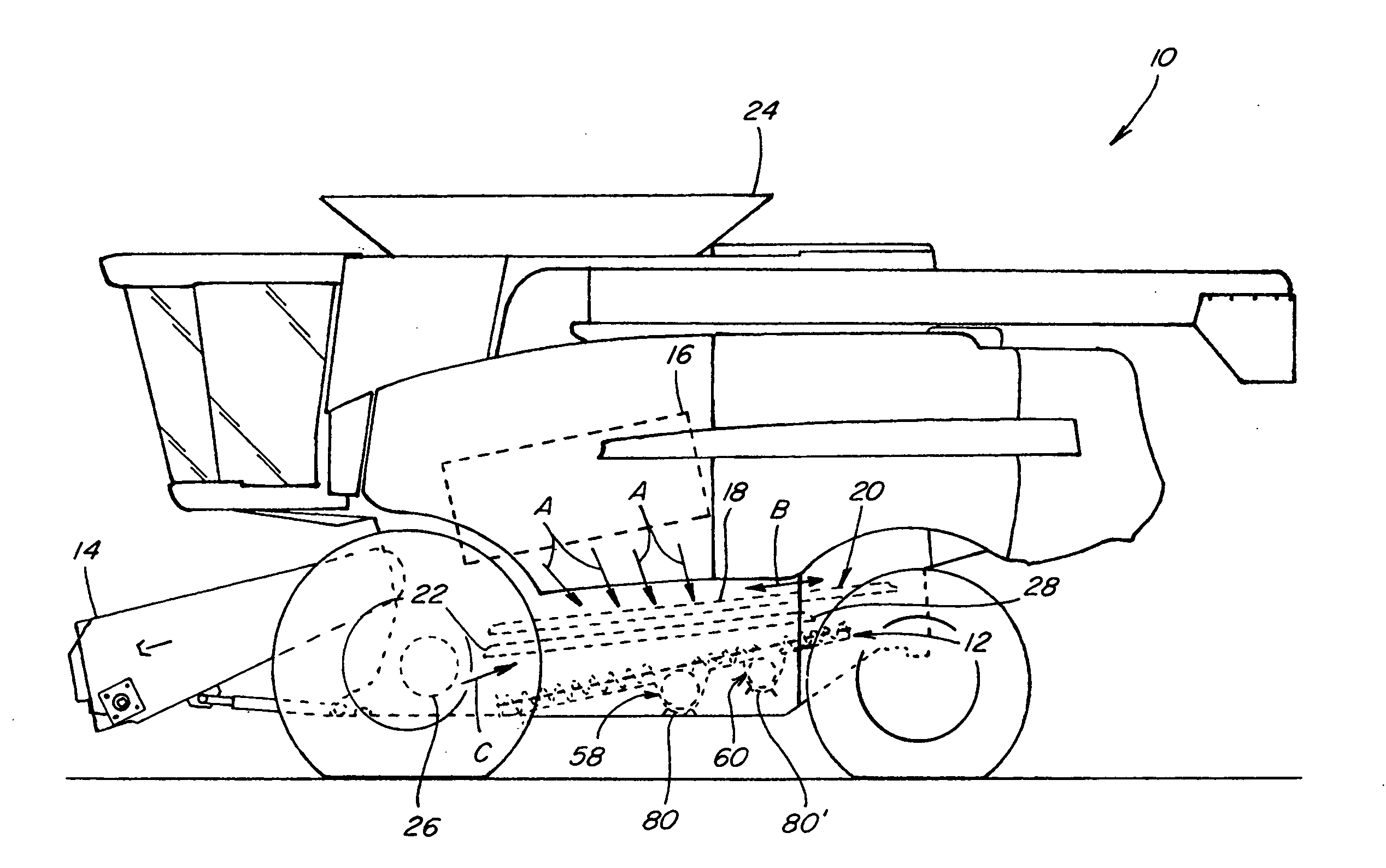

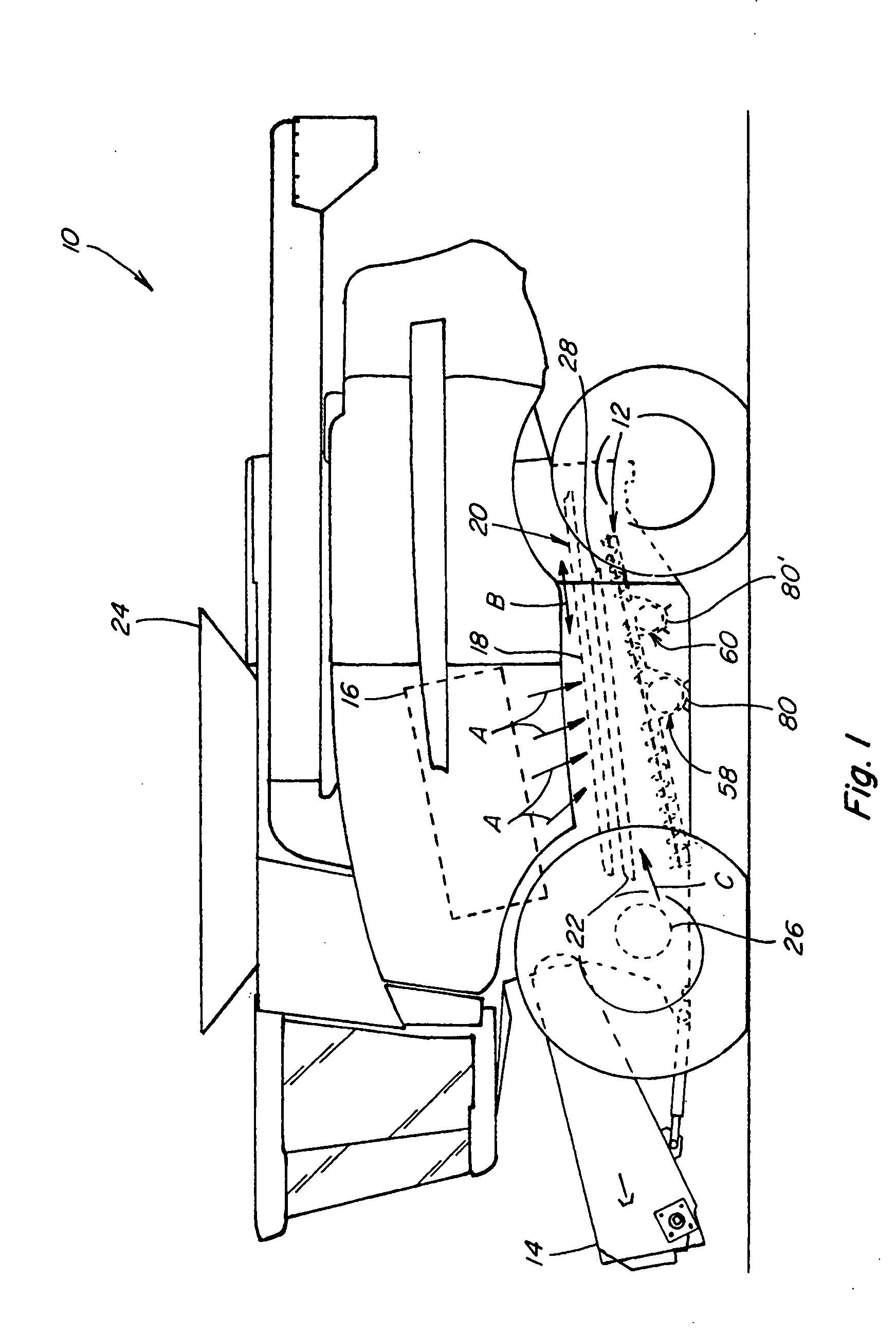

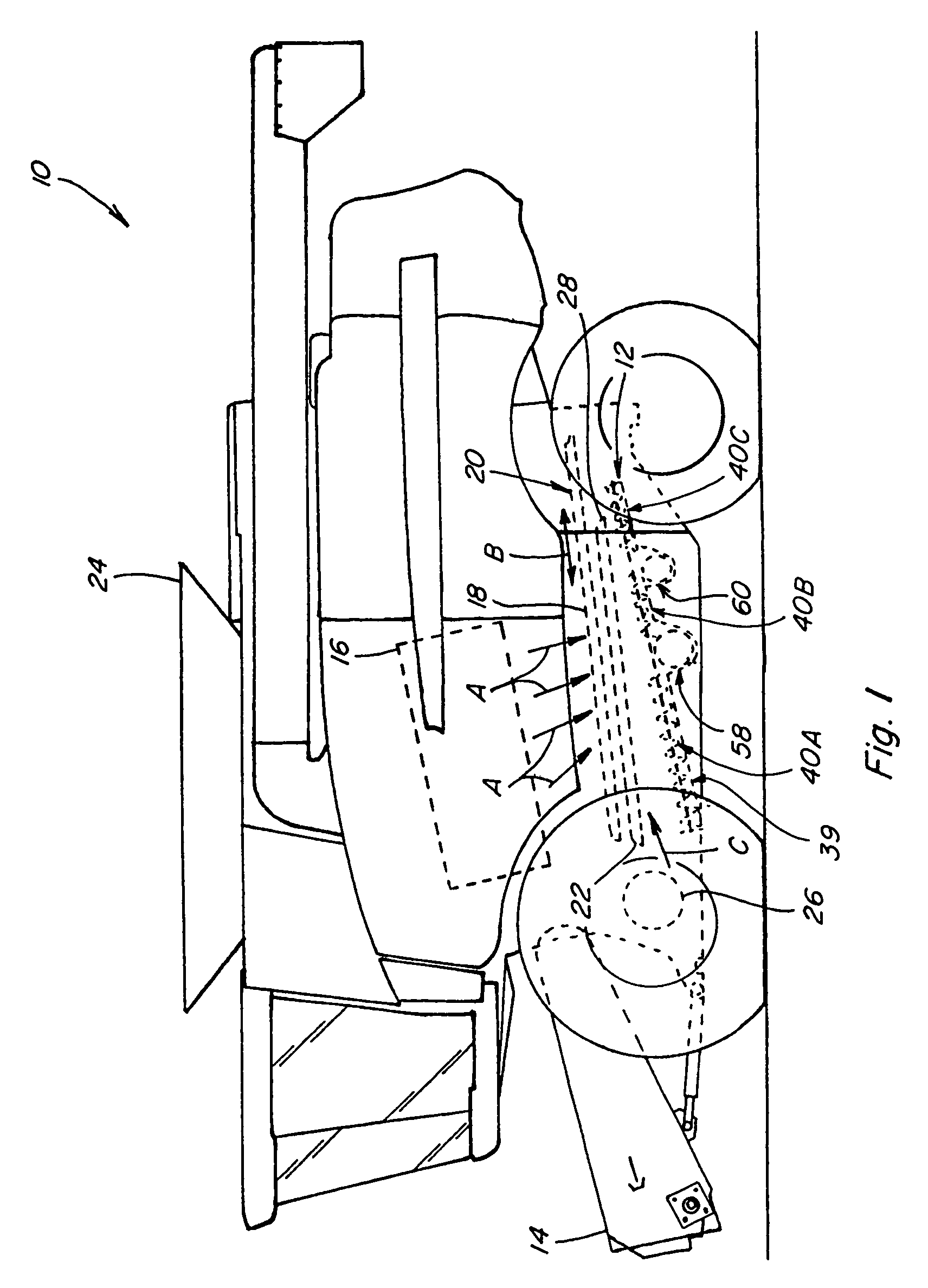

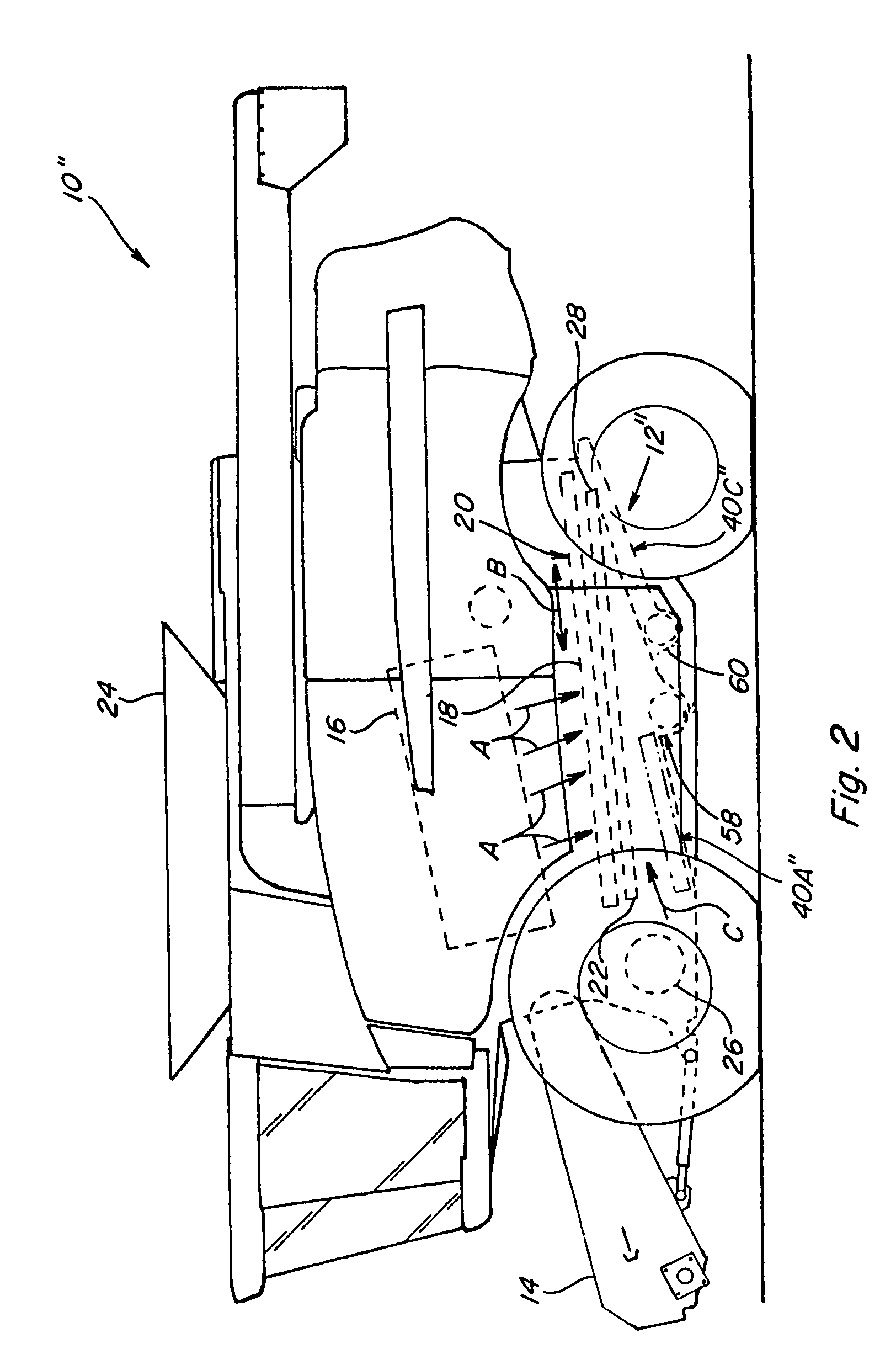

InactiveUS7585213B2Severe build-upGood effectAgricultural machinesThreshersEngineeringCombine harvester

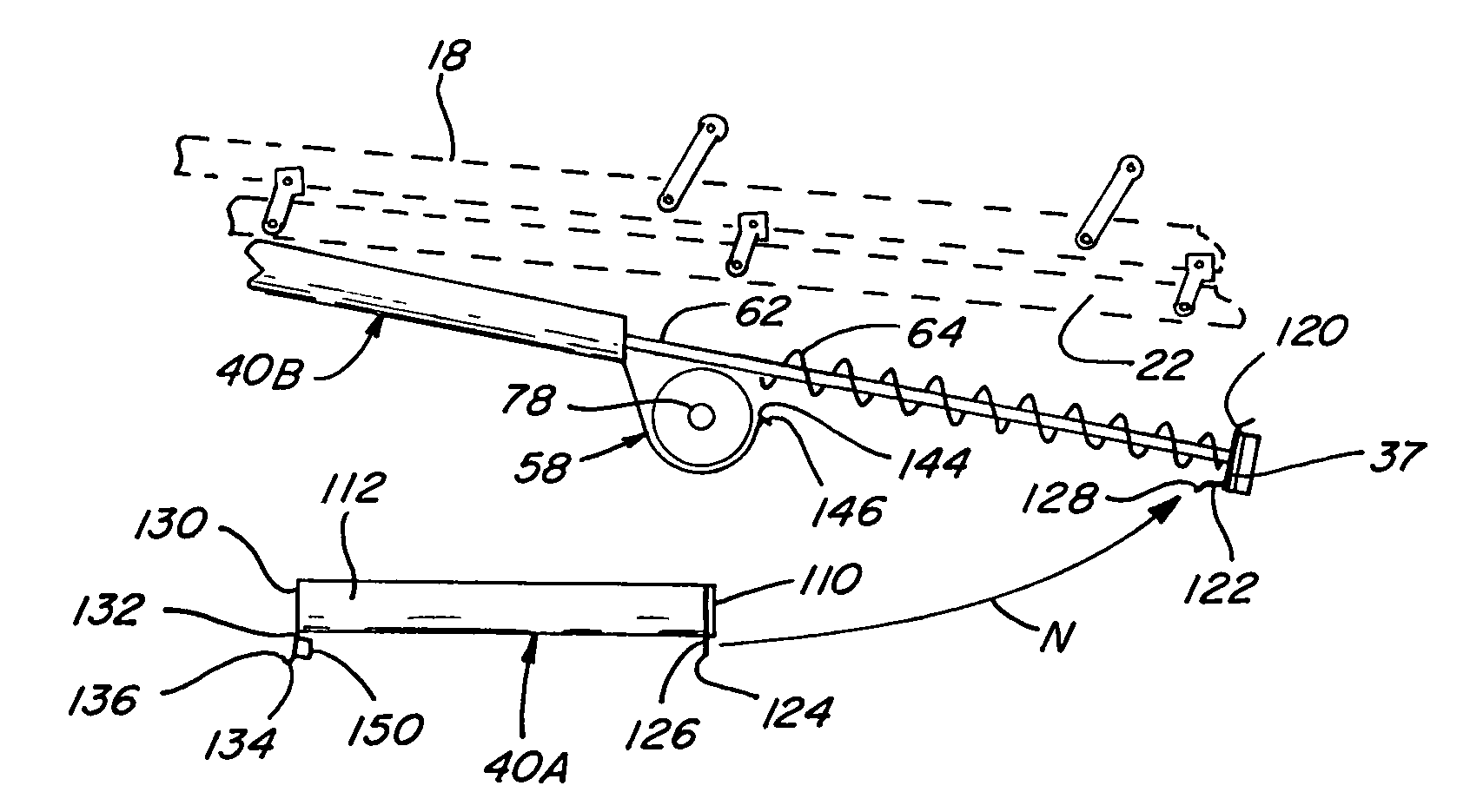

An auger trough and associated clean-out door construction of a clean grain and tailings conveying system for an agricultural combine, such construction including a pair of spaced, depending auger trough side walls that extend laterally across a combine between opposed sidesheets, with a removable door panel positionable across the combine between the opposed sidesheets and between said auger trough side walls to form an auger trough base, which door panel is configured to be so engageable with the auger trough side walls to substantially close the bottom of the auger trough and whose opposite ends are configured to be complementarily engageable with engagement features associated with the sidesheets to maintain such door panel in place during harvesting operations and, with such auger trough side walls, to define a generally rigid trough between the opposed sidesheets. Preferably, the door panel has a first end configured to be engageable with and to rest upon a projecting flange on a first of the opposite sidesheets and a second, latch end with an associated latch mechanism for engaging a complementary latching feature on the second, of the opposed sidesheets for generally securing the door panel in position as the bottom of the auger trough.

Owner:BLUE LEAF I P INC

Auger trough clean-out door

InactiveUS20090186674A1Severe build upEffective effectAgricultural machinesThreshersEngineeringCombine harvester

An auger trough and associated clean-out door construction of a clean grain and tailings conveying system for an agricultural combine, such construction including a pair of spaced, depending auger trough side walls that extend laterally across a combine between opposed sidesheets, with a removable door panel positionable across the combine between the opposed sidesheets and between said auger trough side walls to form an auger trough base, which door panel is configured to be so engageable with the auger trough side walls to substantially close the bottom of the auger trough and whose opposite ends are configured to be complementarily engageable with engagement features associated with the sidesheets to maintain such door panel in place during harvesting operations and, with such auger trough side walls, to define a generally rigid trough between the opposed sidesheets. Preferably, the door panel has a first end configured to be engageable with and to rest upon a projecting flange on a first of the opposite sidesheets and a second, latch end with an associated latch mechanism for engaging a complementary latching feature on the second of the opposed sidesheets for generally securing the door panel in position as the bottom of the auger trough.

Owner:BLUE LEAF I P

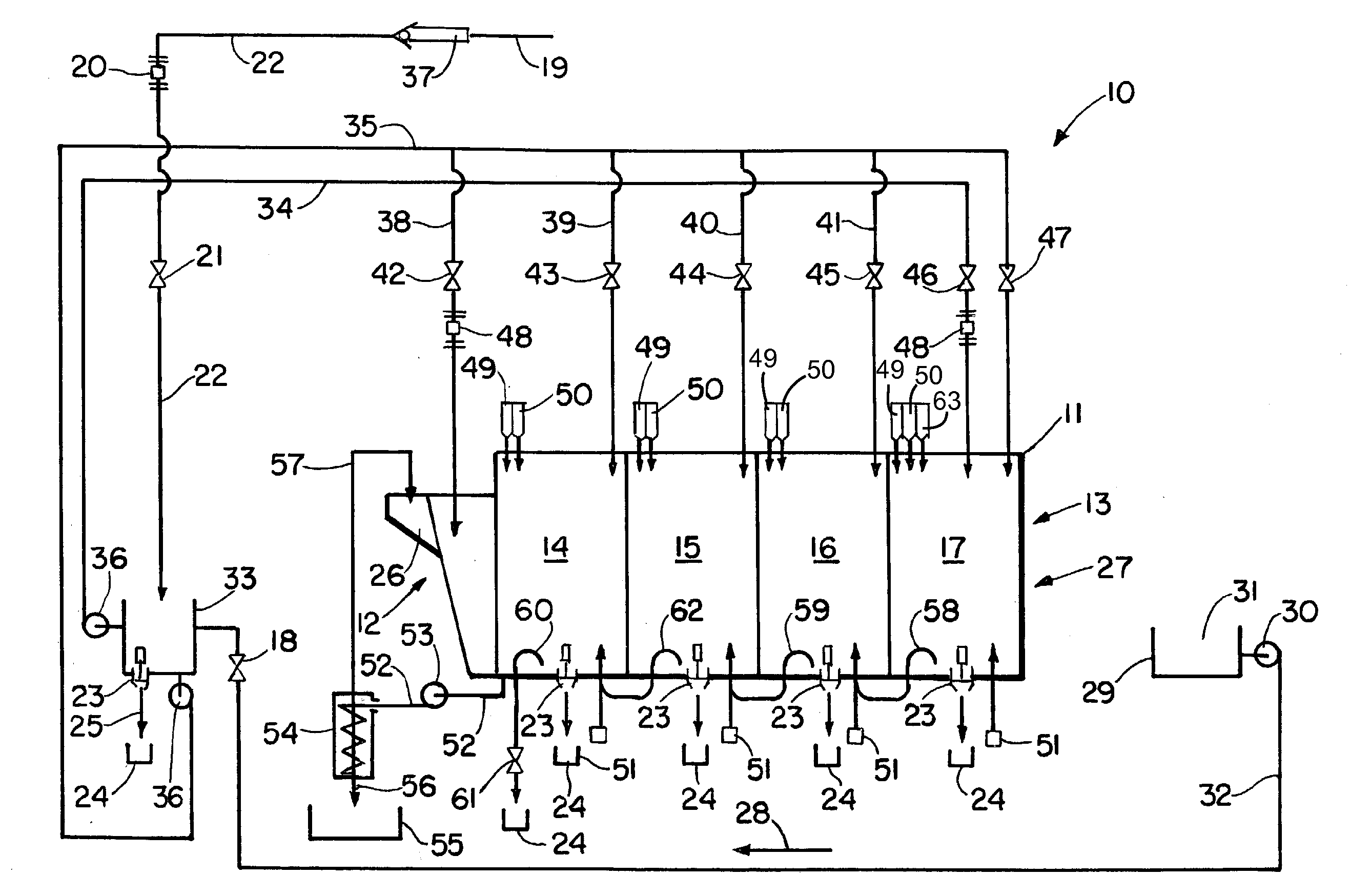

Floor mat and particulate laden material washing apparatus and method

InactiveUS20150167221A1Improve performanceMaintains washing qualityOther washing machinesDetergent compounding agentsParticulatesCounter flow

A method of washing particulate laden material in a washer includes moving the particulate laden material from the intake of the washer to the discharge of the washer and through multiple modules or sectors. Liquid can be counter flowed in the washer interior along a flow path that is generally opposite the direction of travel of the particulate laden material. A specially configured recirculation / filtration arrangement removes a majority of particulate and organic matter from the washing fluid.

Owner:PELLERIN MILNOR

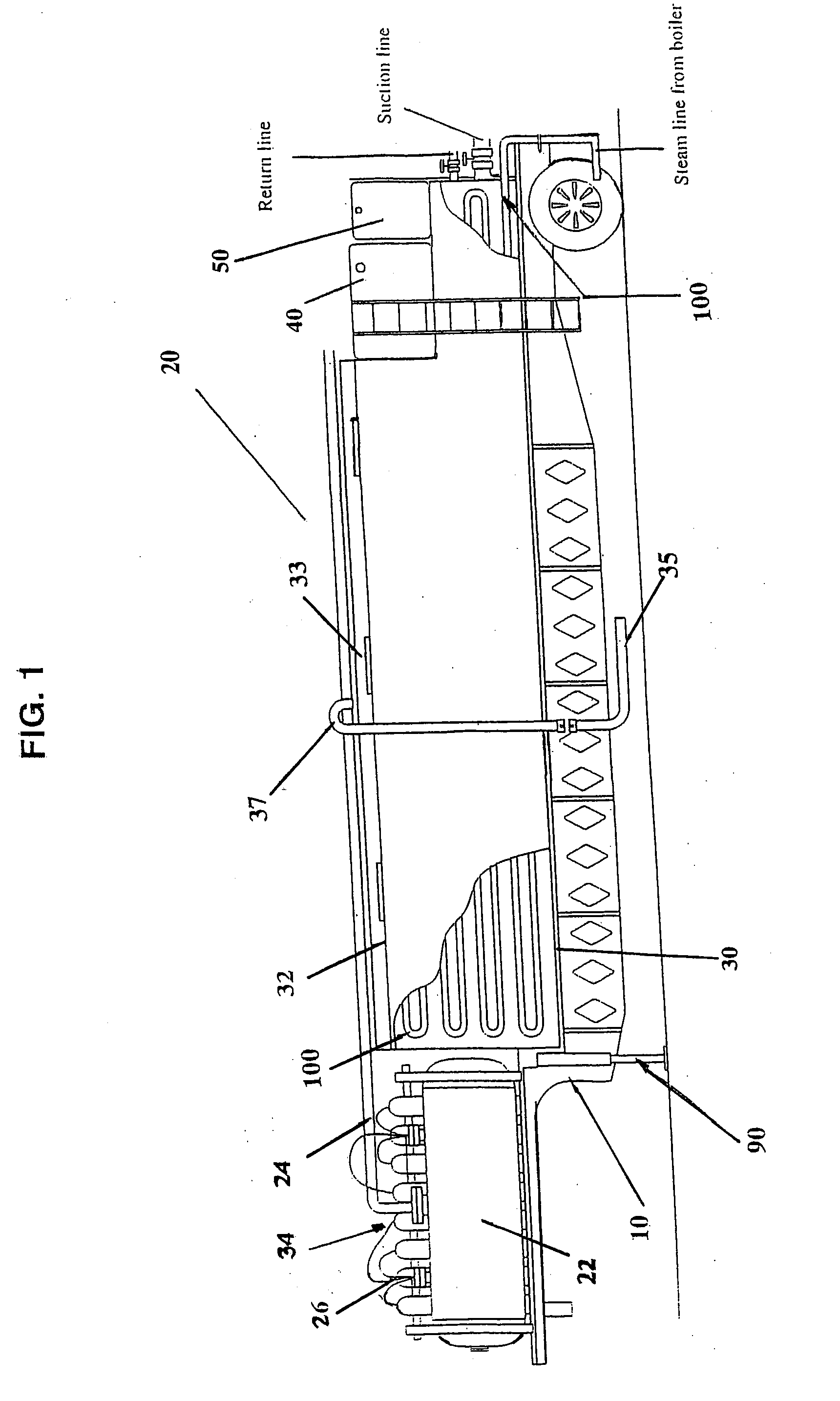

Solar Water Heater

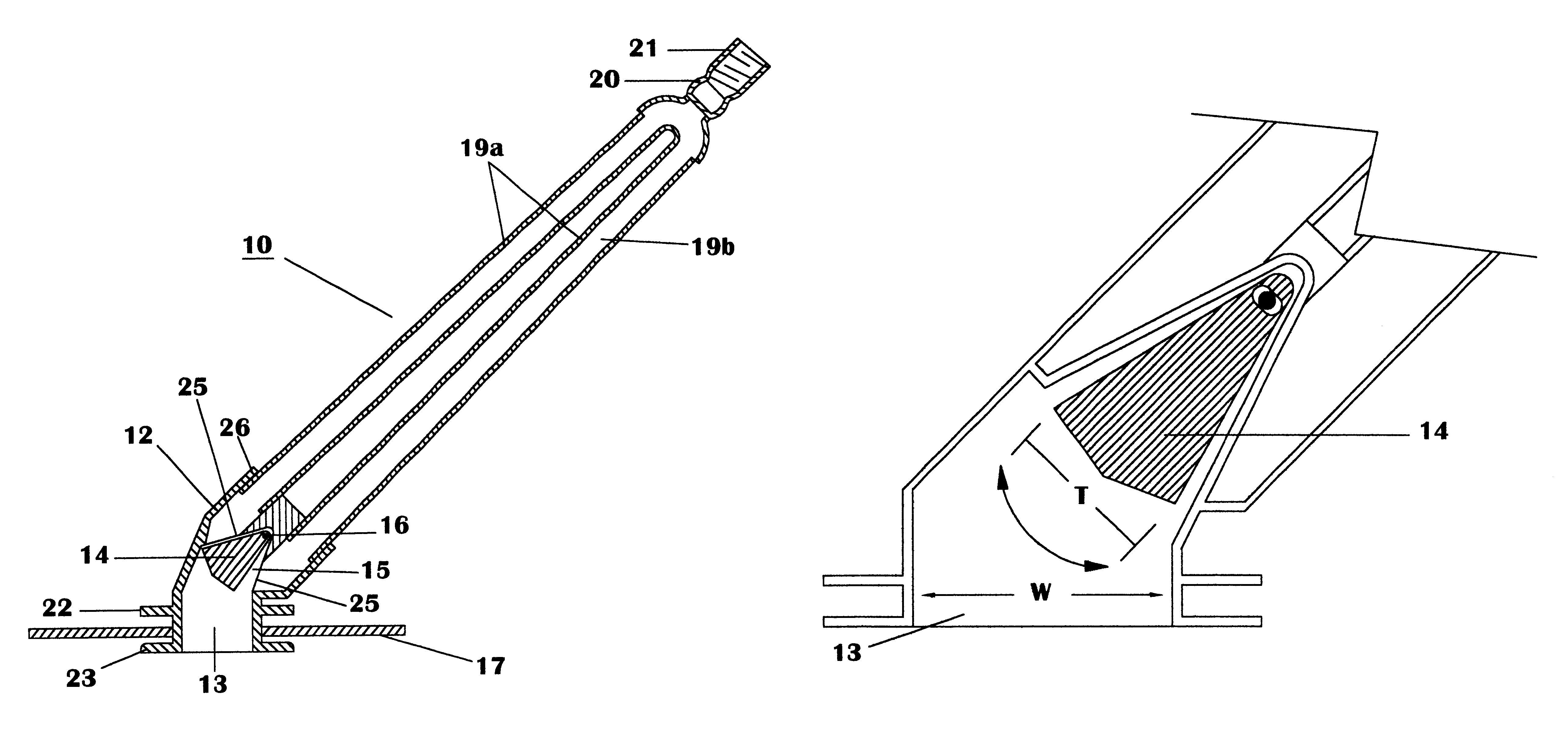

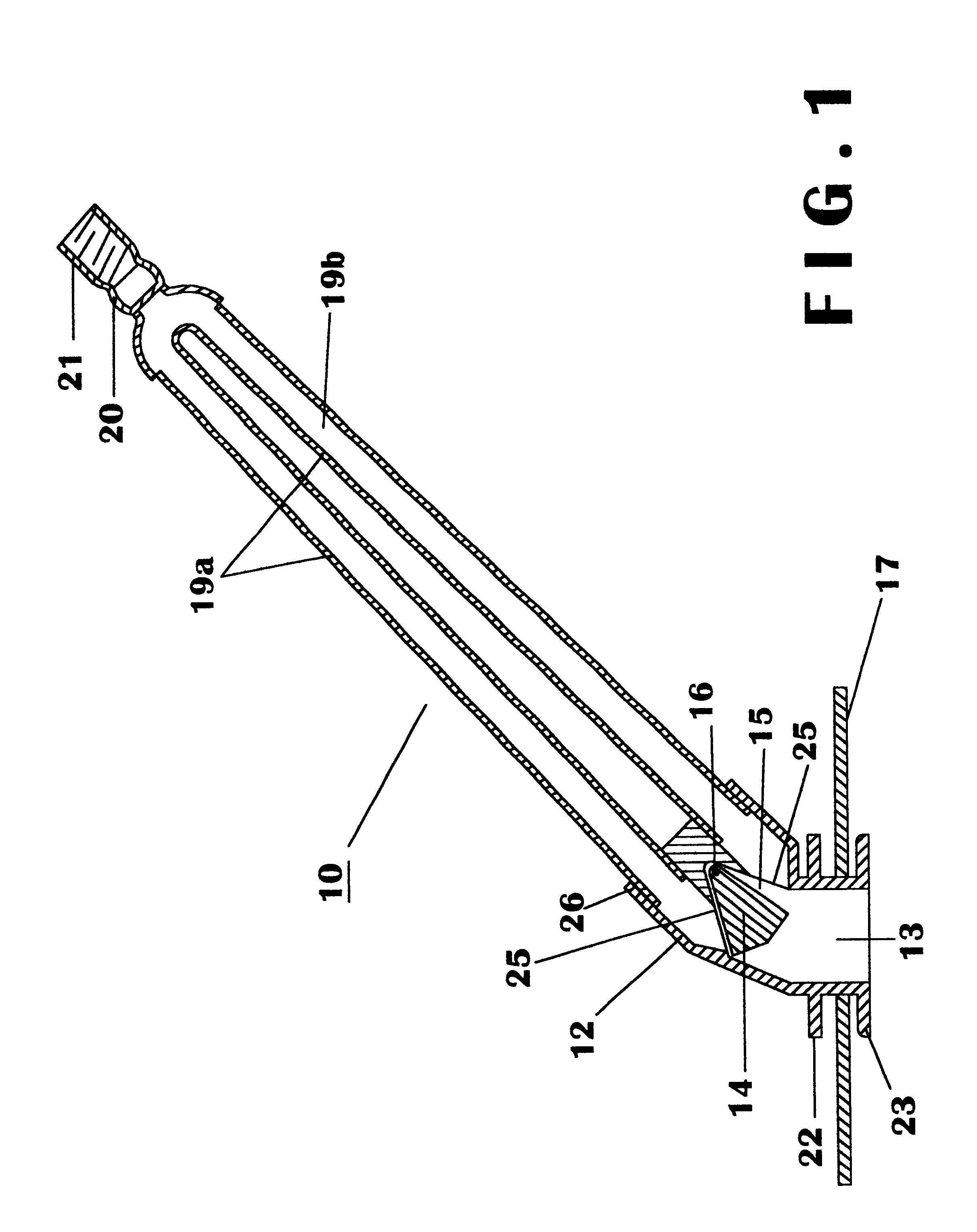

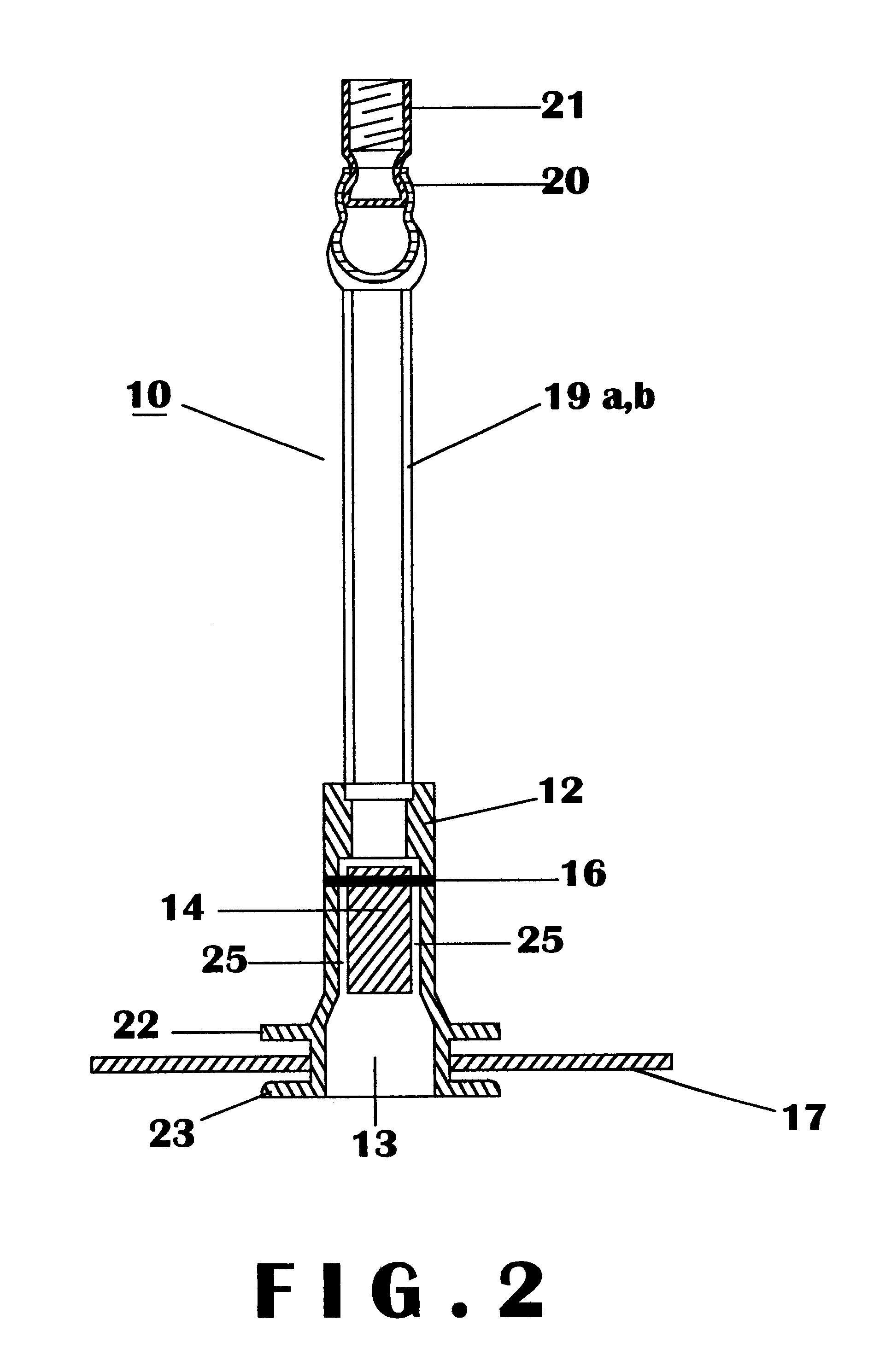

InactiveUS20110146665A1Improve efficiencyLow costSolar heating energySolar heat devicesWorking fluidSolar water

A lightweight and low cost solar water heating apparatus which is comprised of an insulated container with a transparent cover enclosing a folded tank is provided. The tank is comprised of a lightweight material which is folded into a shape that allows any seams in the material to be held above the surface of fluid within the tank. The folded tank further contains a working fluid which absorbs solar energy when the tank is exposed to sun light through the transparent cover. A length of lightweight pipes is coiled in a serpentine fashion within the folded tank and is surrounded by the working fluid. Pressurized supply water flows through the serpentine length of pipe and absorbs heat from the working fluid as it travels through the folded tank. The heated supply water is then used as pre-heated supply water for a standard hot water heater.

Owner:SCHARFE RONALD E

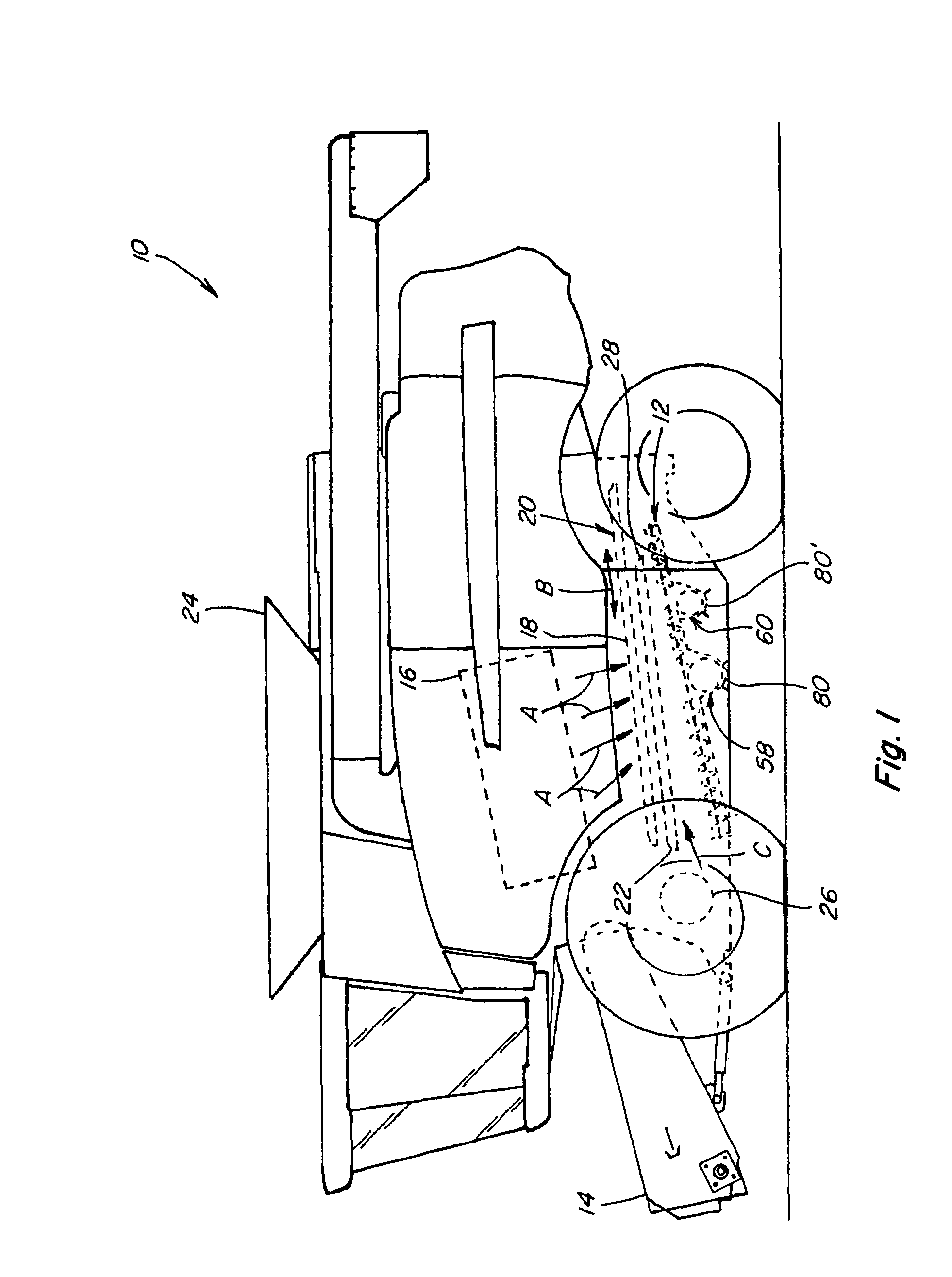

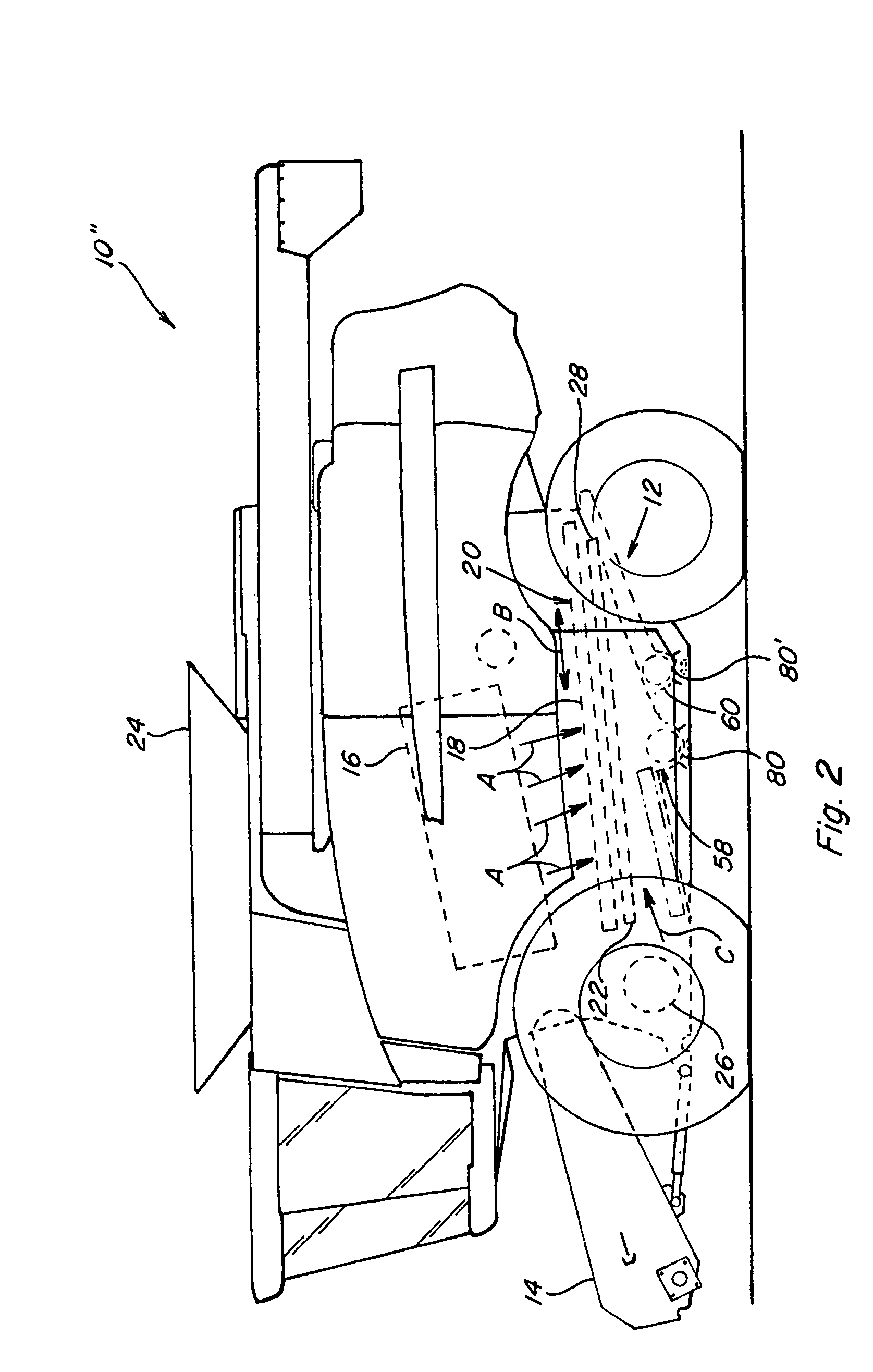

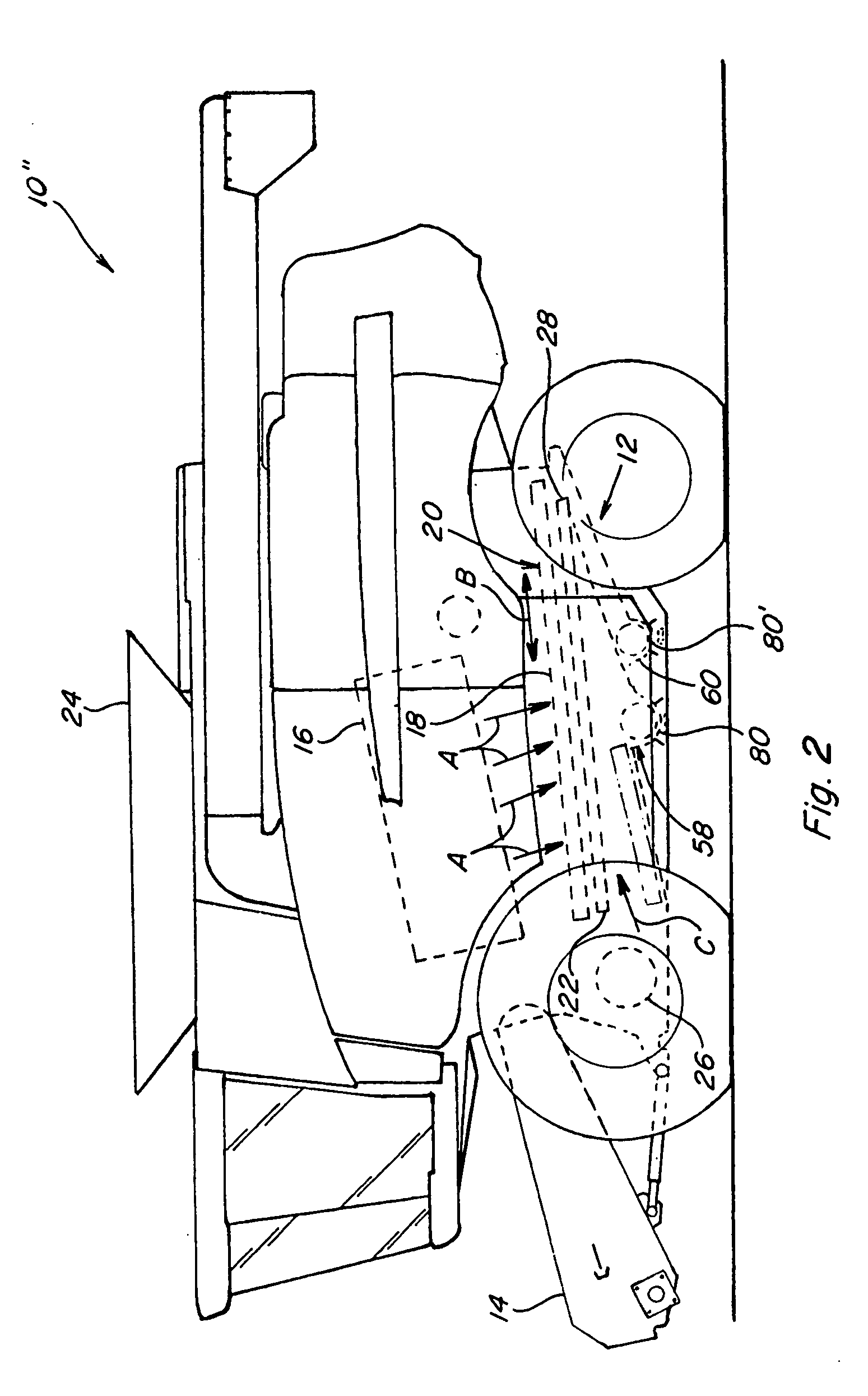

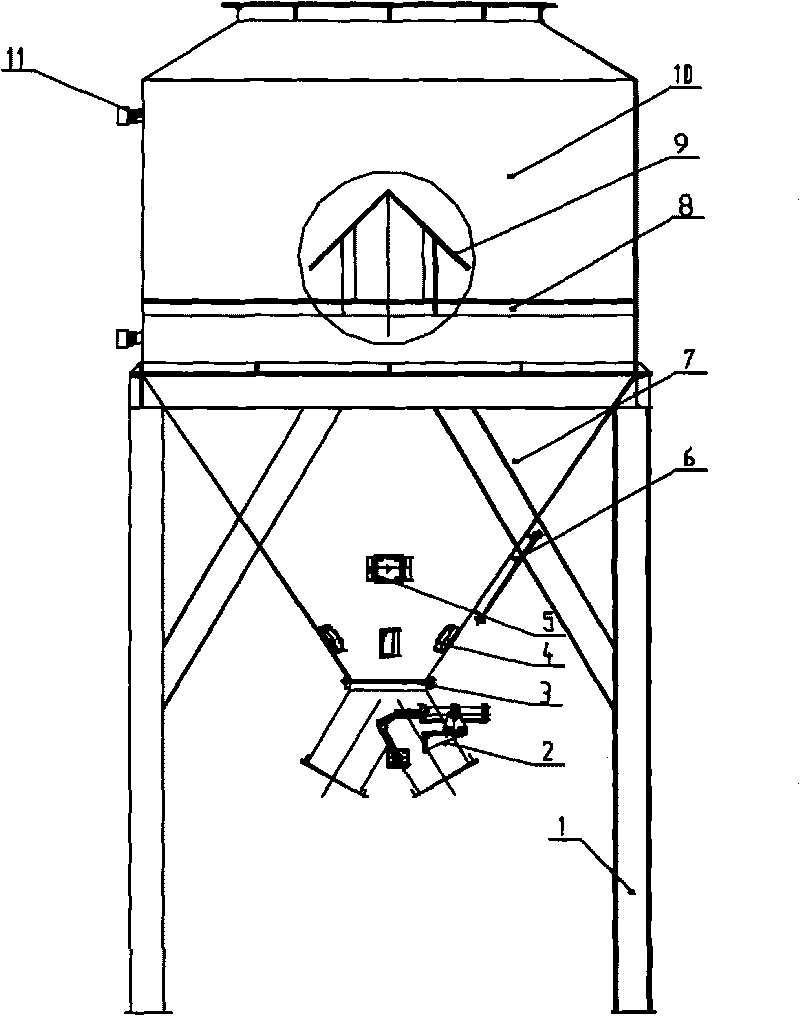

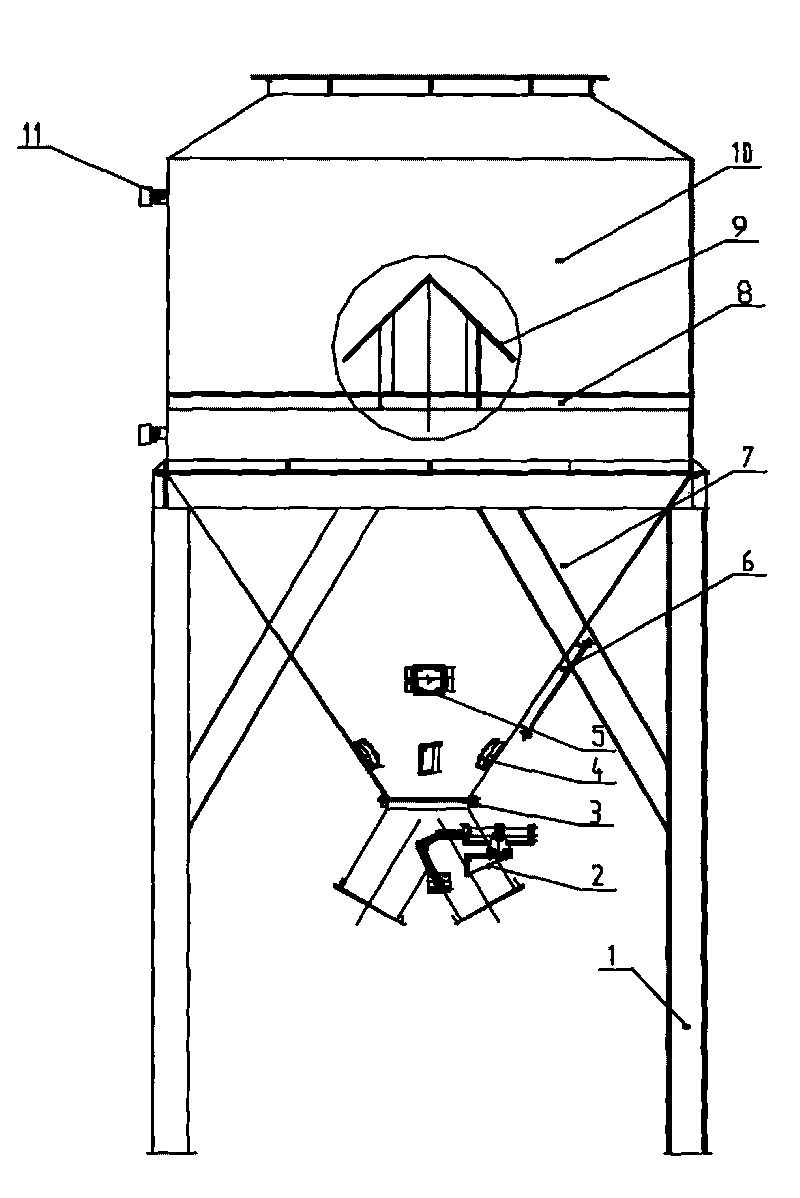

Collecting trough construction easily accessible for cleaning

InactiveUS7632183B2Satisfied with the effectEasily conveyedAgricultural machinesThreshersCombine harvesterDelivery system

A collecting trough construction for facilitating the clean out of collecting troughs of clean grain and tailings collecting and conveying systems of agricultural combines, such collecting trough construction including a base pan sized and dimensioned to extend longitudinally between first and second cross-pieces of such a collecting and conveying system, one of which cross-pieces may be a clean grain auger trough or a tailings auger trough, and laterally generally between the sidesheets of a combine, with collecting troughs formed in the upper side thereof, which base pan has first and second ends and is positionable between the first and second cross-pieces with the first end of the auger trough base pan adjacent the first cross-piece and the second end of the auger trough base pan adjacent the second cross-piece to be readily complementarily engageable therewith and wholly or partially disengageable therefrom by a user to permit convenient access to the formed collecting troughs for cleaning thereof. Preferably, the base pan is, alternatively, partially detachable to permit access for cleaning by a user in an in-place clean-out position or wholly removable to permit the removal of such base pan to a remote location for cleaning by the user thereat.

Owner:BLUE LEAF I P INC

Finished product bin of dry-mixed mortar station

InactiveCN101733844AReduce the distance of free fallReduce shockDischarging apparatusFree fallingEngineering

The invention provides a finished product bin of a dry-mixed mortar station. The bin comprises a bottom frame, and a bin body which is arranged on the bottom frame and consists of an upper bin body and a lower bin body, wherein the lower bin body is bucket-shaped, the side wall of the lower bin body is provided with an access hole, and the bottom part of the lower bin body is connected with a material discharge tube; a buffer device is arranged in the upper bin body, and the upper and the lower parts of the upper bin body are both provided with a bin level indicator; the lower bin body is provided with a vibrator, and the part, close to a material discharge opening, of the lower bin body is provided with a plurality of flow assisting gas bowls; and the material discharge tube is provided with two outlets provided with pneumatic three-way valves for controlling the opening and closing of the two outlets. Due to the use of the buffer device, a free falling distance of the dry-mixed mortar is reduced, the impact and noise caused by the falling of the dry-mixed mortar are reduced, the separation of the dry-mixed mortar is avoided effectively and the compacting action on the stored dry-mixed mortar is prevented; and due to the use of the pneumatic and vibrating devices, the problem that the dry-mixed mortar is glued on the inner surface of the lower bin body is solved effectively. In addition, the finished product bin also has the advantages of simple structure, convenient use, easy maintenance, noise reduction and clean and smooth material discharge.

Owner:徐州天地重型机械制造有限公司

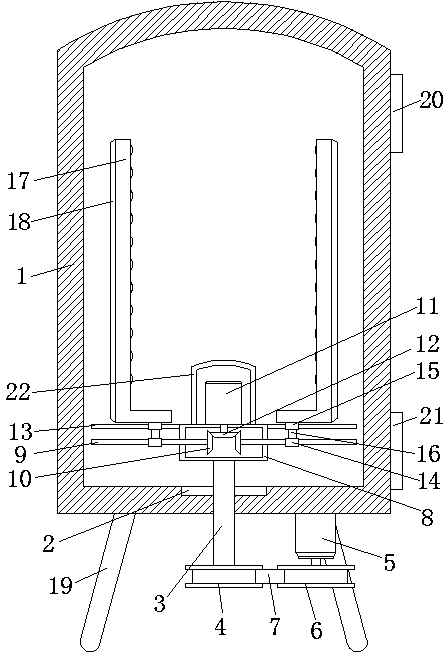

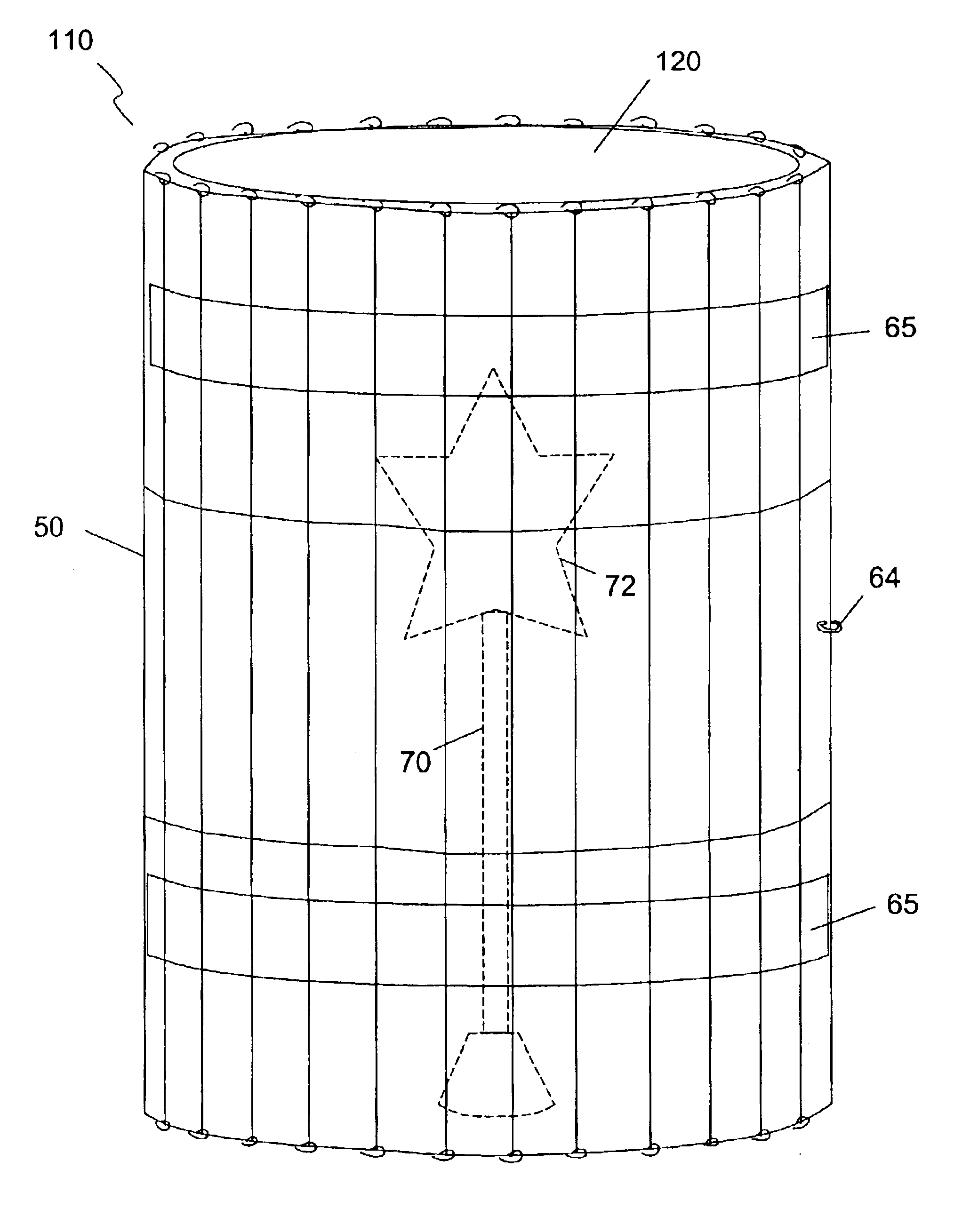

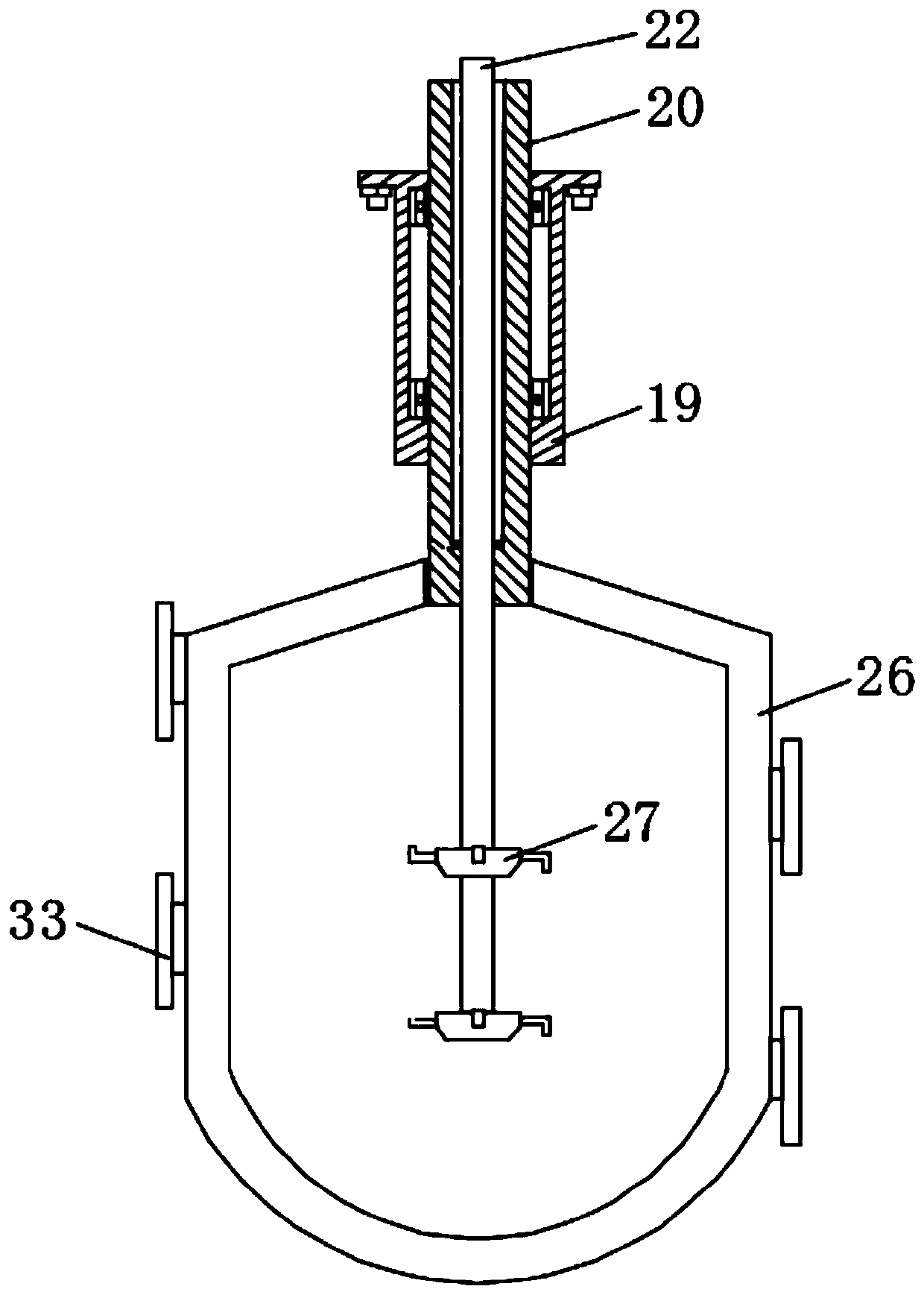

Biological fermentation tank convenient to clean

PendingCN107760555AEasy to cleanClean outBioreactor/fermenter combinationsBiological substance pretreatmentsGear wheelLap joint

The invention discloses a biological fermentation tank convenient to clean, which comprises a tank body. A bearing is connected to the bottom part of an inner wall of the tank body in a clamping way;a rotary shaft is inserted into the bearing; a first belt pulley is fixedly connected to the bottom end of the rotary shaft; a drive motor is fixedly connected to a lower surface of the tank body; anoutput shaft of the drive motor is fixedly connected with a second belt pulley; the first belt pulley and the second belt pulley are in transmission connection through a belt; a gear box is fixedly connected to the top end of the rotary shaft. According to the biological fermentation tank convenient to clean provided by the invention, the motor operates to drive a second bevel gear to rotate, thesecond bevel gear drives a threaded rod to rotate, and a screw thread is limited by a limiting rod and a slide sleeve so as to be incapable of rotating, so that the screw thread sleeves on the threaded rod so as to move along a direction of the threaded rod; a screw thread sleeve moves outwards to enable a scraper blade on the outer side of a stir rod to be in lap joint with the inner wall of thetank body, so that the stir rod can scrape residues attached to the inner wall of the tank body when rotating, and not only is the fermentation tank clean in discharging, but also the fermentation tank is convenient to clean.

Owner:江苏棉海园林工程有限公司

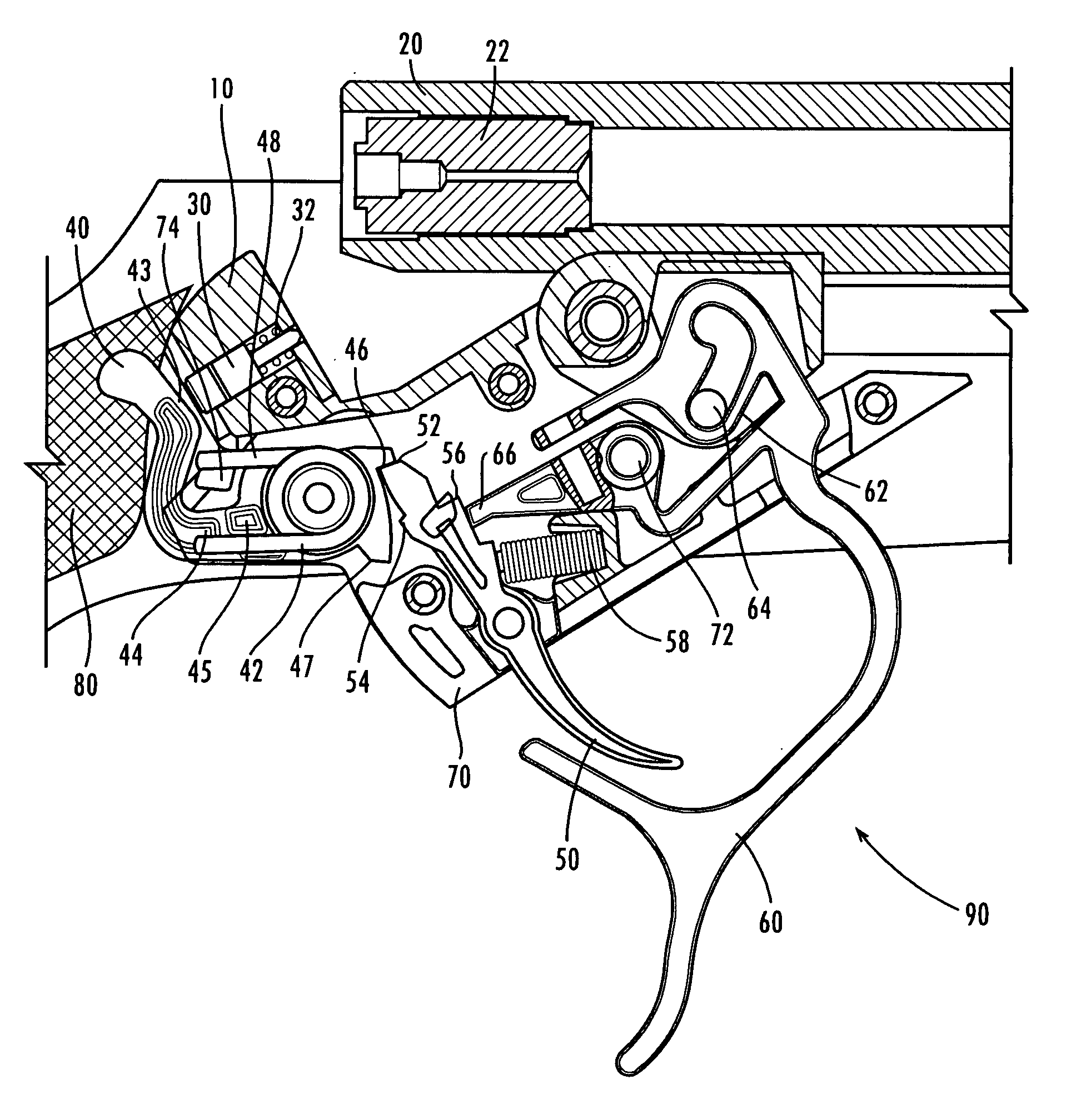

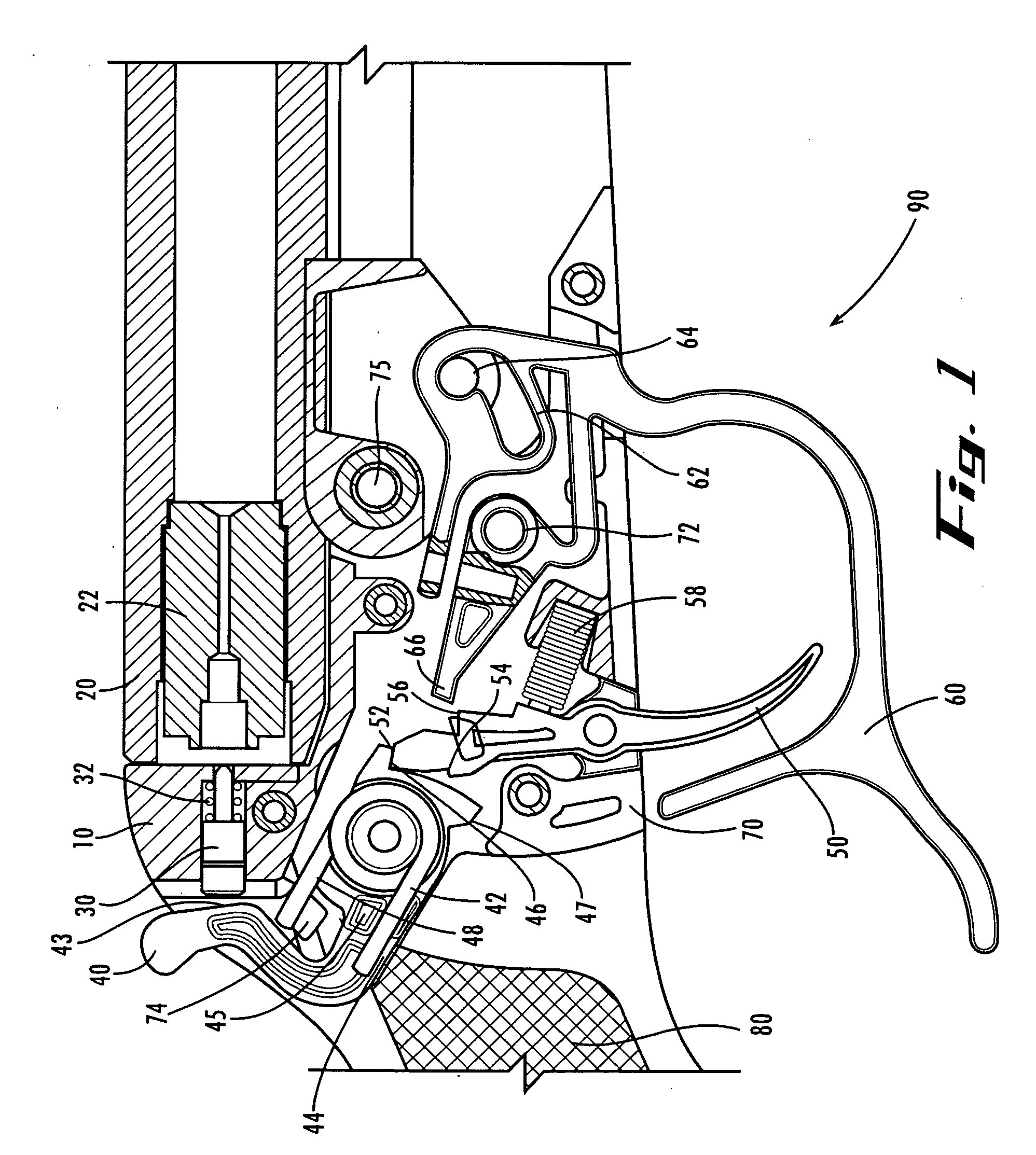

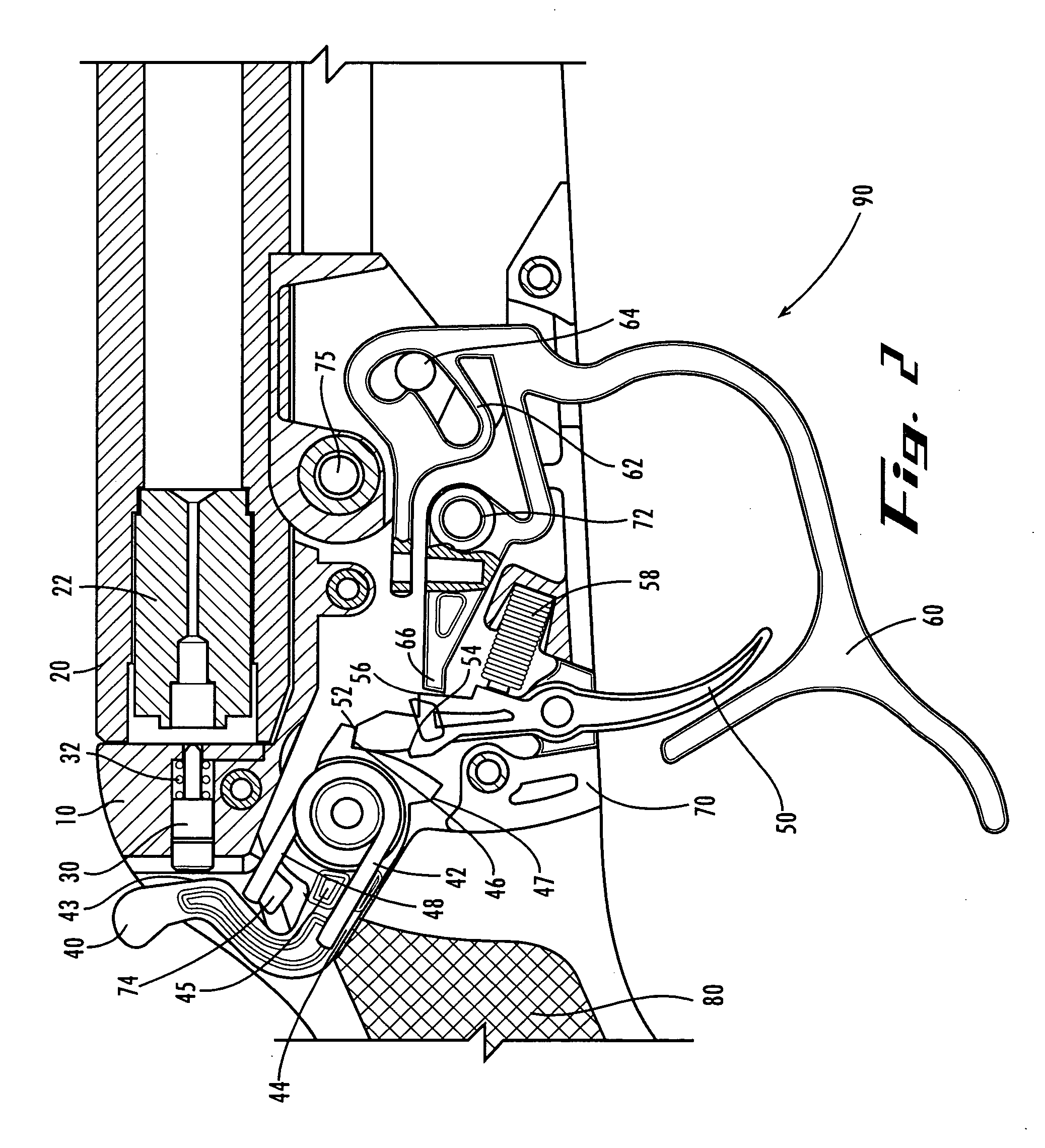

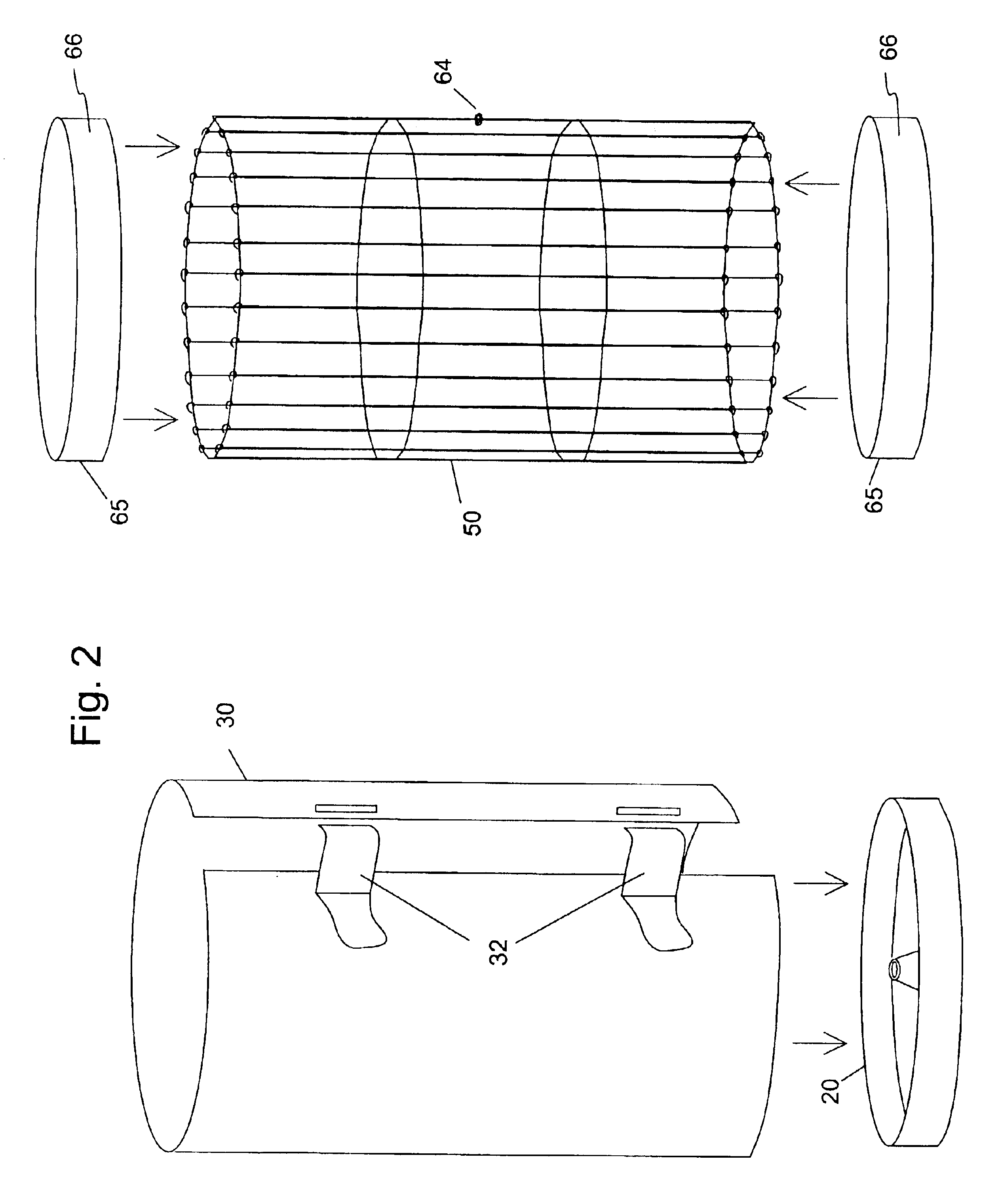

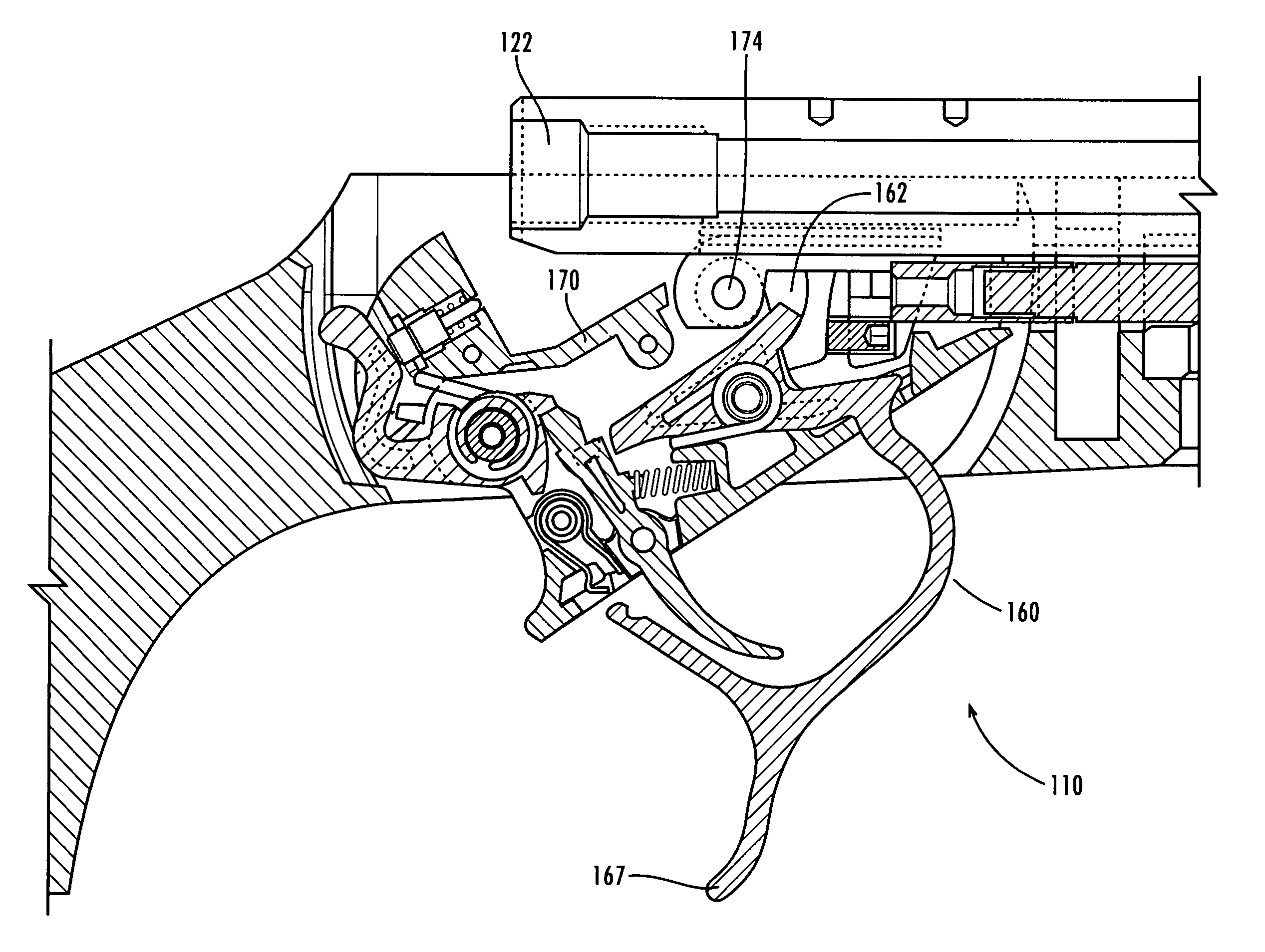

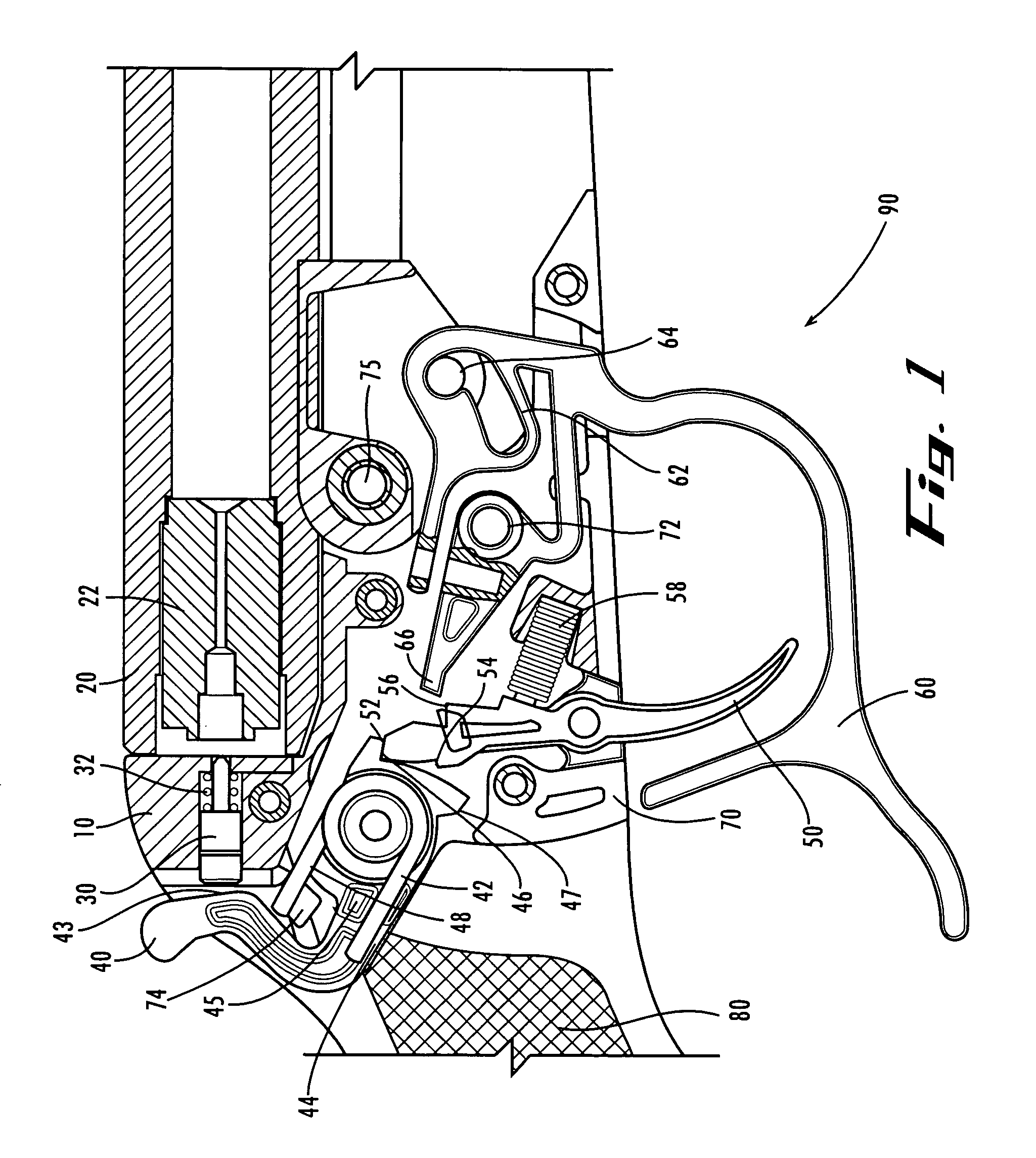

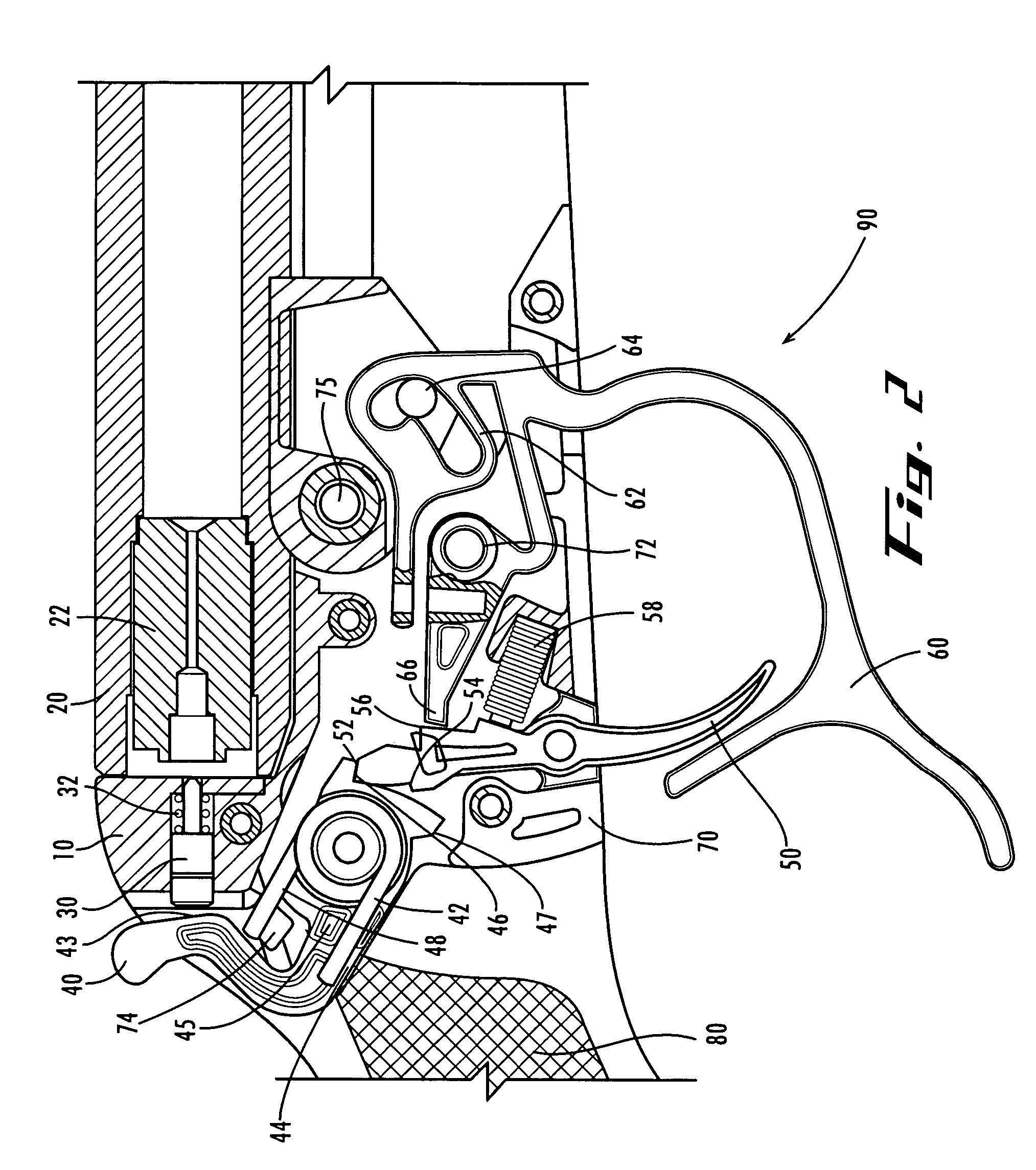

Muzzle-loading firearm with pivoting block action

InactiveUS20070039222A1Clean outEasy to replaceBreech mechanismsMuzzle-loading smallarmsDetonatorAerospace engineering

A muzzle-loading firearm having a barrel and a pivoting firing mechanism. The barrel has a breech plug, a pivoting junction axle, and a blocking axle, and the firing mechanism has a trigger, hammer, striker and notch. The firing mechanism is pivotally attached to the barrel at the pivoting junction axle and the blocking axle is movably aligned in the notch. When the firing mechanism is pivoted, it is guided by the blocking axle in the notch ensuring sufficient clearance between said firing mechanism for easy placement of a percussion cap.

Owner:BLACKPOWDER PRODS

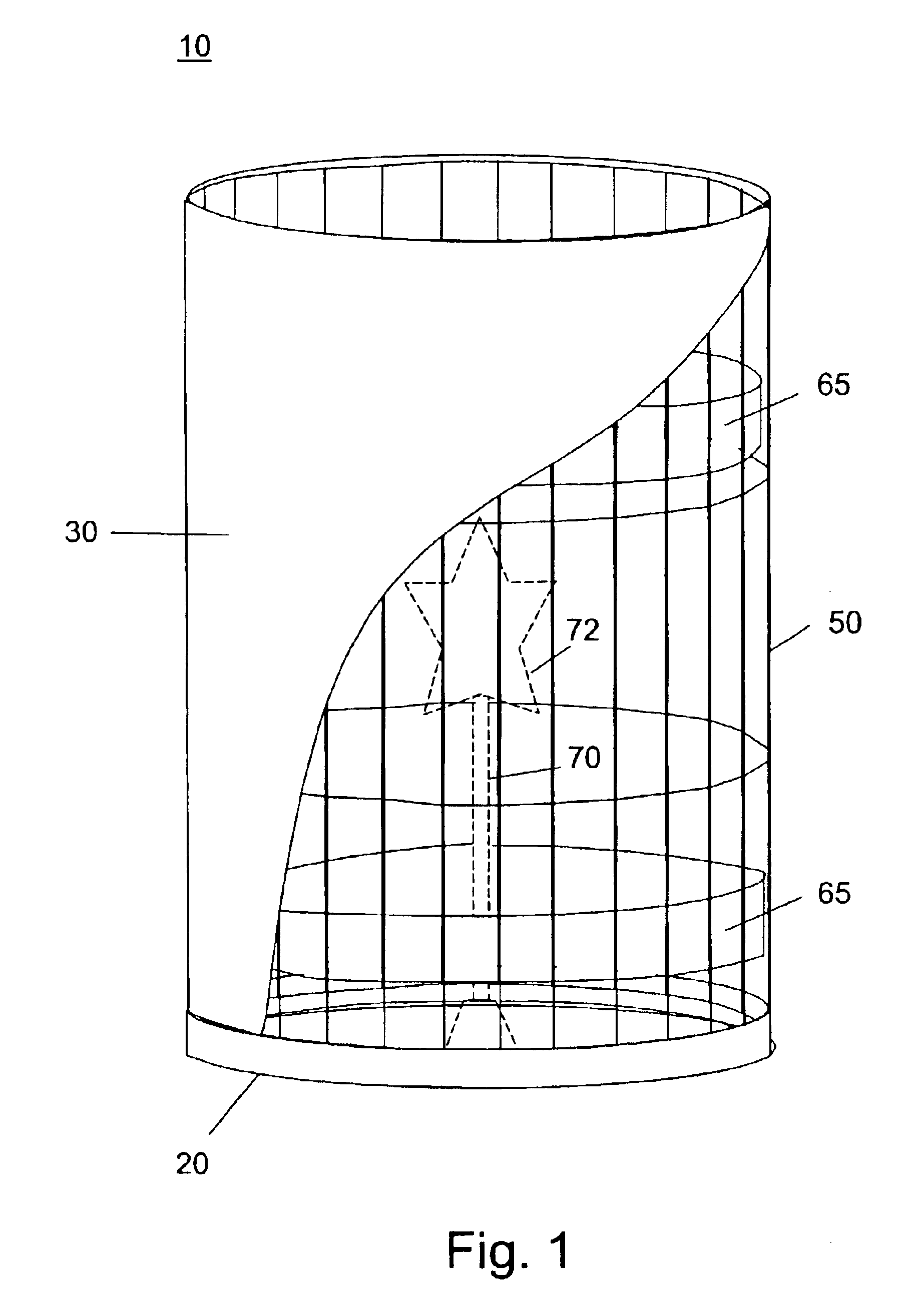

Solid investment molding system and method

InactiveUS6892789B2Minimize cracksQuicker moisture removalFoundry mouldsFoundry coresWaxThree dimensional shape

A lost wax molding system has a re-usable, collapsible, chain-linked mesh exoskeleton, one or more inserts to be placed within the interior surface of the mesh exoskeleton to exert outward pressure on the mesh exoskeleton thereby creating a pre-formed, rigid, three-dimensional shape, a waterproof sleeve sized to cover the outer surface of the three-dimensional shape, and a base sized to seal said waterproof sleeve forming an investment mold container.

Owner:BOYLE MICHAEL

Muzzle-loading firearm with pivoting block action

InactiveUS7065913B2Clean outEasy to replaceBreech mechanismsMuzzle-loading smallarmsAerospace engineeringEngineering

A muzzle-loading firearm having a barrel and a pivoting firing mechanism. The barrel has a breech plug, a pivoting junction axle. and a blocking axle, and the firing mechanism has a trigger, hammer, striker and notch. The firing mechanism is pivotally attached to the barrel at the pivoting junction axle and the blocking axle is movably aligned in the notch. When the firing mechanism is pivoted, it is guided by the blocking axle in the notch ensuring sufficient clearance between said firing mechanism for easy placement of a percussion cap.

Owner:BLACKPOWDER PRODS

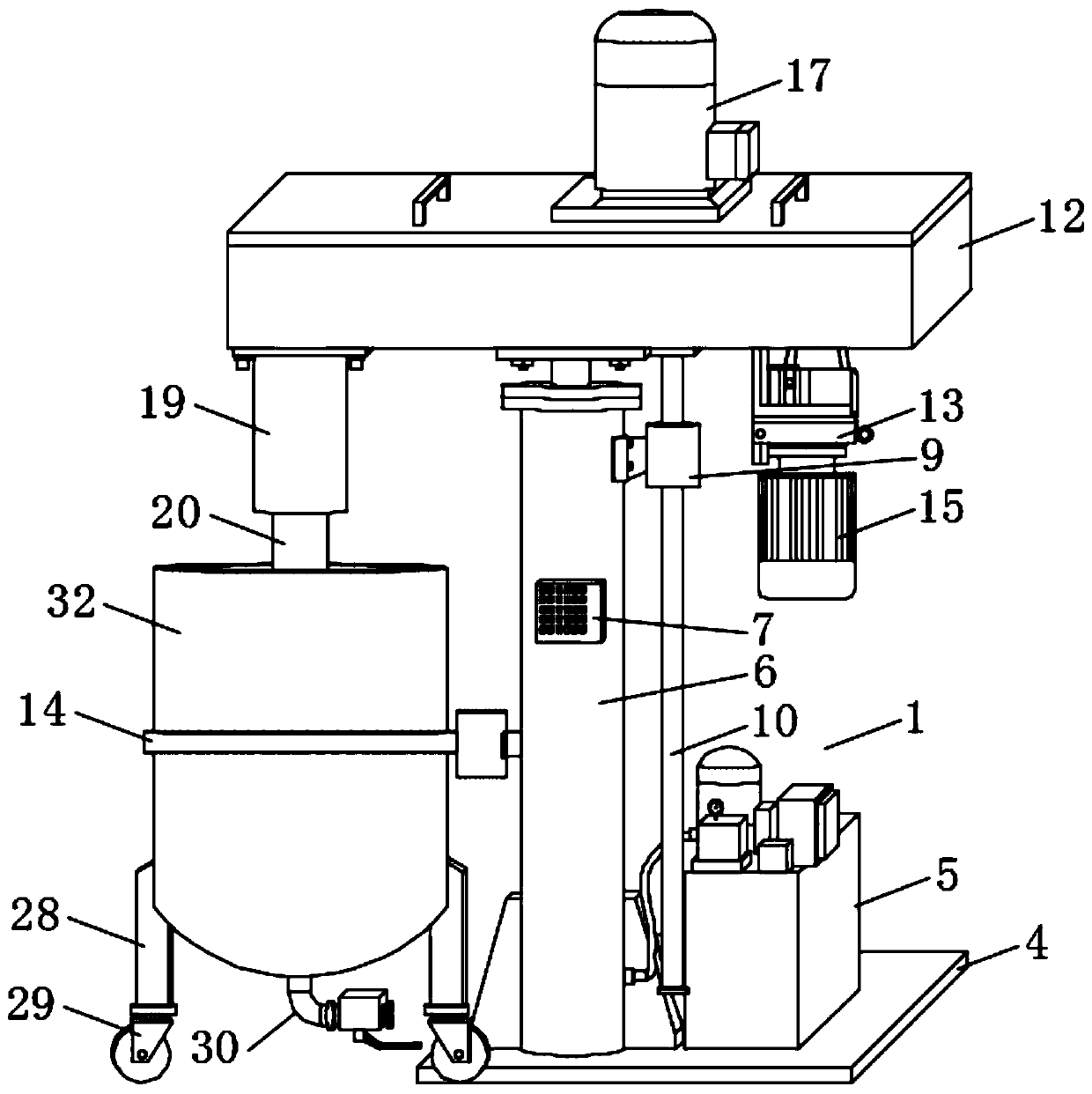

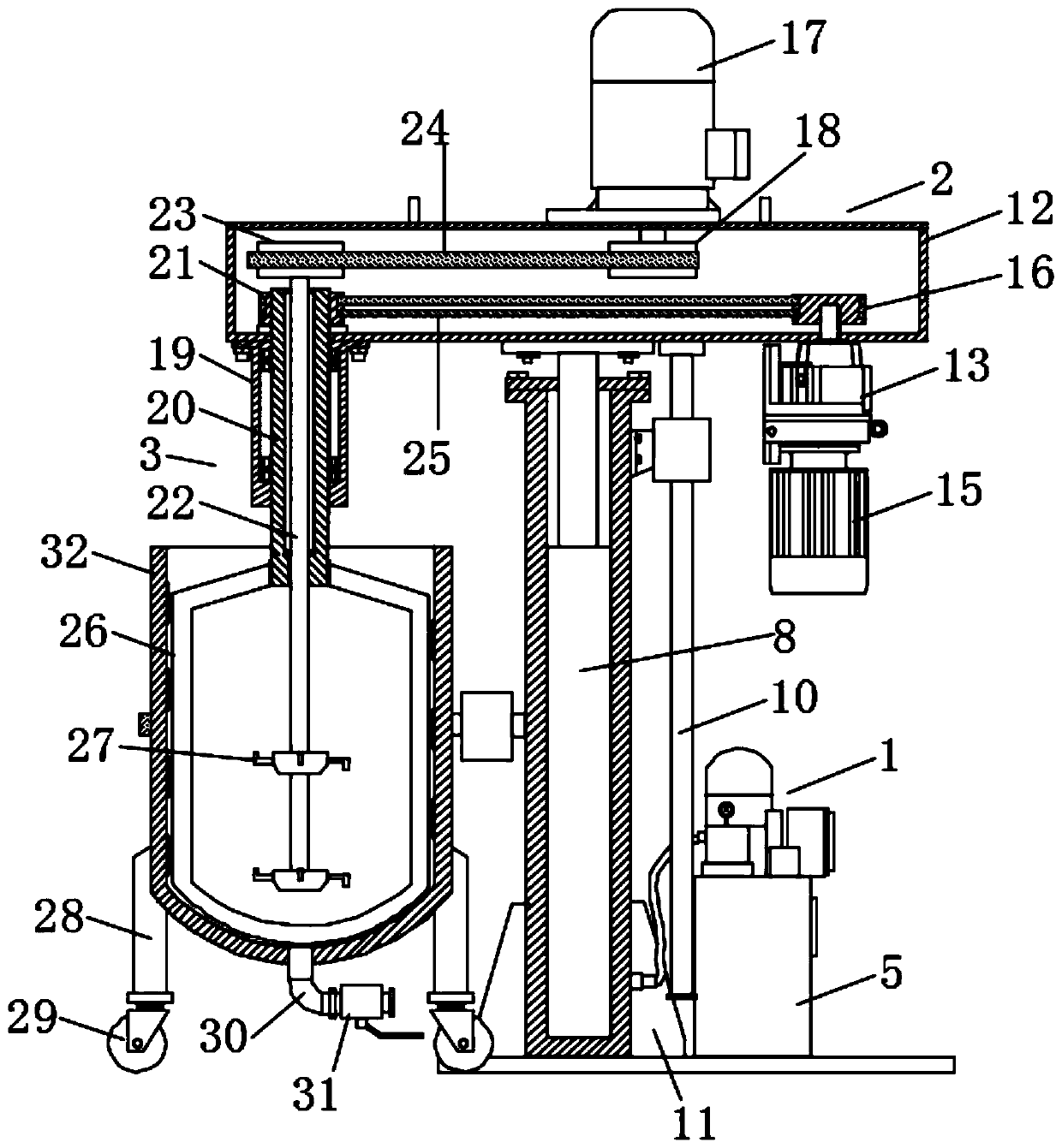

Concentric double-shaft dispersion machine with wall scraping function

InactiveCN110898708AImprove stirring efficiencyImprove qualityRotary stirring mixersTransportation and packagingEngineeringAgitator

The invention discloses a concentric double-shaft dispersion machine with wall scraping function. The dispersion machine comprises a lifting mechanism, a power mechanism, a dispersing mechanism and astorage tank. The power mechanism is disposed above the lifting mechanism, one end of the power mechanism is equipped with the dispersing mechanism. The invention has the beneficial effects that: by setting the dispersing mechanism and high-speed dispersing discs, two groups of stirrers work simultaneously, so that materials are subjected to strong shearing and mixing effects, and the purpose of rapid mixing is achieved; the dispersing mechanism falls into an anchor type and a butterfly type, an optimal stirring form can be designed according to materials of different viscosities and specificgravities and different production process requirements, the equipment uses an oil cylinder serving as a lifting actuator, a control valve is arranged to control the rising, stop and descending of a working head, the operation is simple, and the stability is high; a stirring paddle and a main shaft are fixed by a fixed bolt, thereby facilitating disassembly and replacement, and being easy to clean; and a belt holding clip has different clamping modes, so that a stirring barrel can be quickly fixed, and safety accidents caused by displacement of the barrel in the working process are prevented.

Owner:望江县江华设备制造有限公司

Collecting trough construction easily accessible for cleaning

InactiveUS20090215510A1Easy accessQuickly and easily re-positionedAgricultural machinesThreshersCombine harvesterDelivery system

A collecting trough construction for facilitating the clean out of collecting troughs of clean grain and tailings collecting and conveying systems of agricultural combines, such collecting trough construction including a base pan sized and dimensioned to extend longitudinally between first and second cross-pieces of such a collecting and conveying system, one of which cross-pieces may be a clean grain auger trough or a tailings auger trough, and laterally generally between the sidesheets of a combine, with collecting troughs formed in the upper side thereof, which base pan has first and second ends and is positionable between the first and second cross-pieces with the first end of the auger trough base pan adjacent the first cross-piece and the second end of the auger trough base pan adjacent the second cross-piece to be readily complementarily engageable therewith and wholly or partially disengageable therefrom by a user to permit convenient access to the formed collecting troughs for cleaning thereof. Preferably, the base pan is, alternatively, partially detachable to permit access for cleaning by a user in an in-place clean-out position or wholly removable to permit the removal of such base pan to a remote location for cleaning by the user thereat.

Owner:BLUE LEAF I P INC

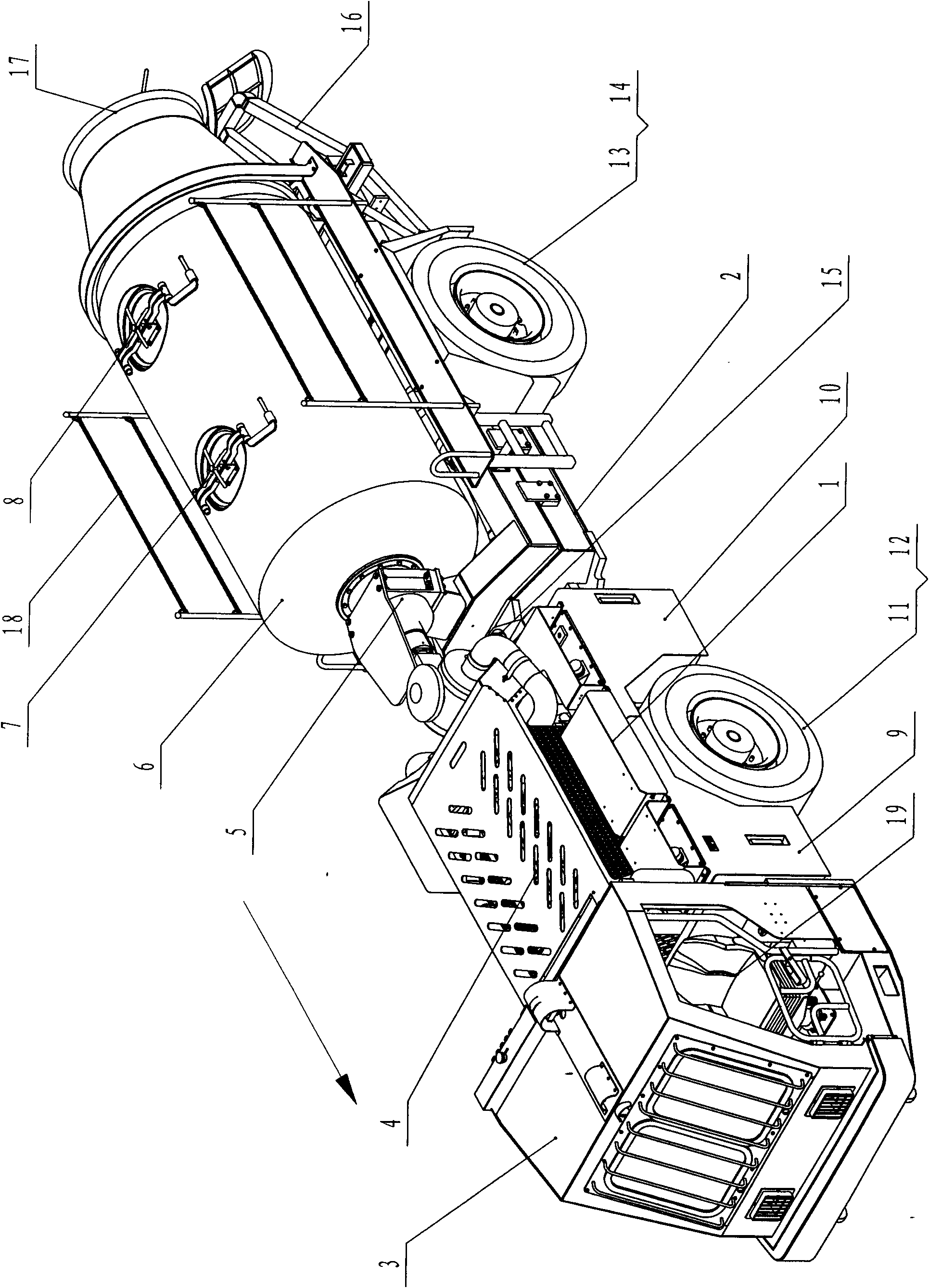

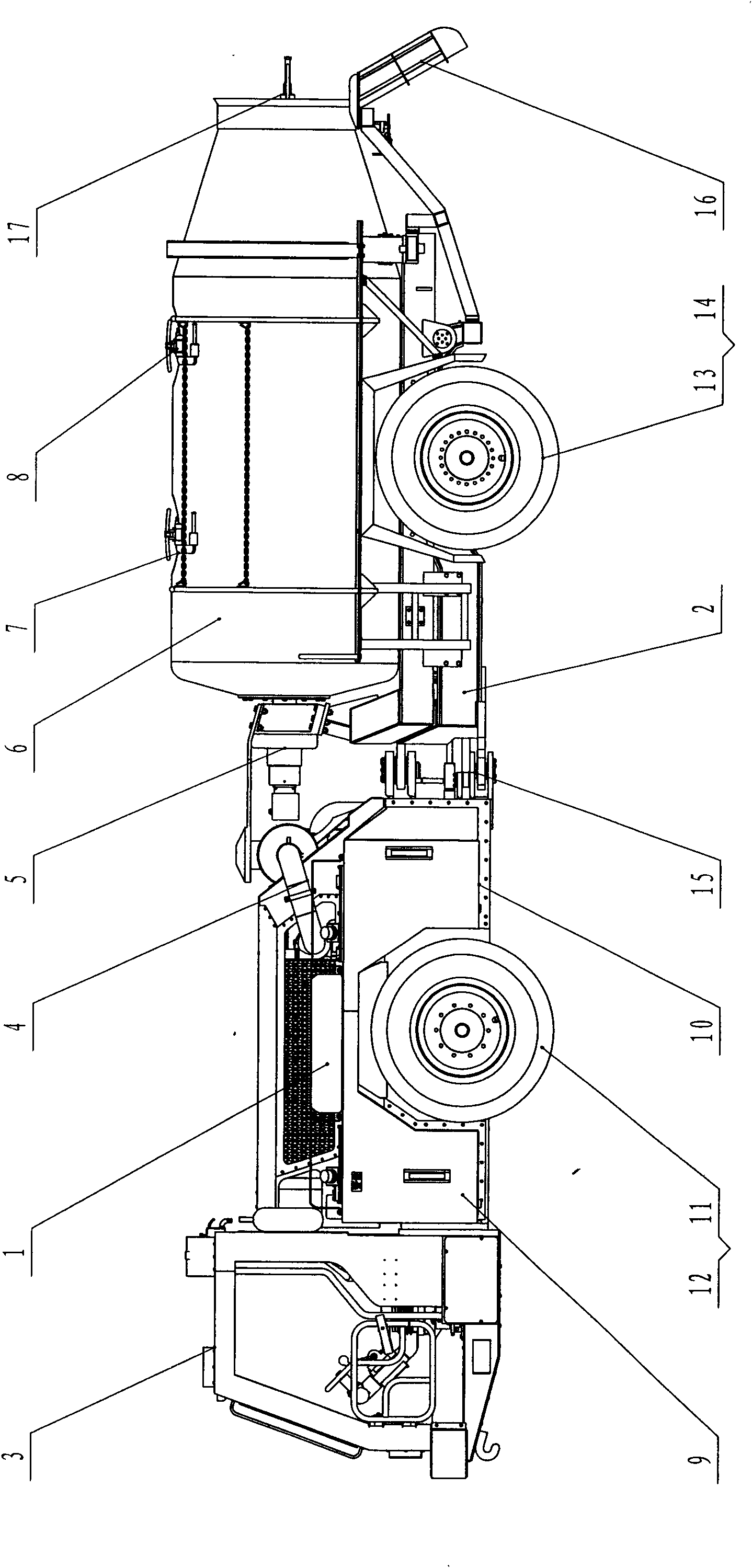

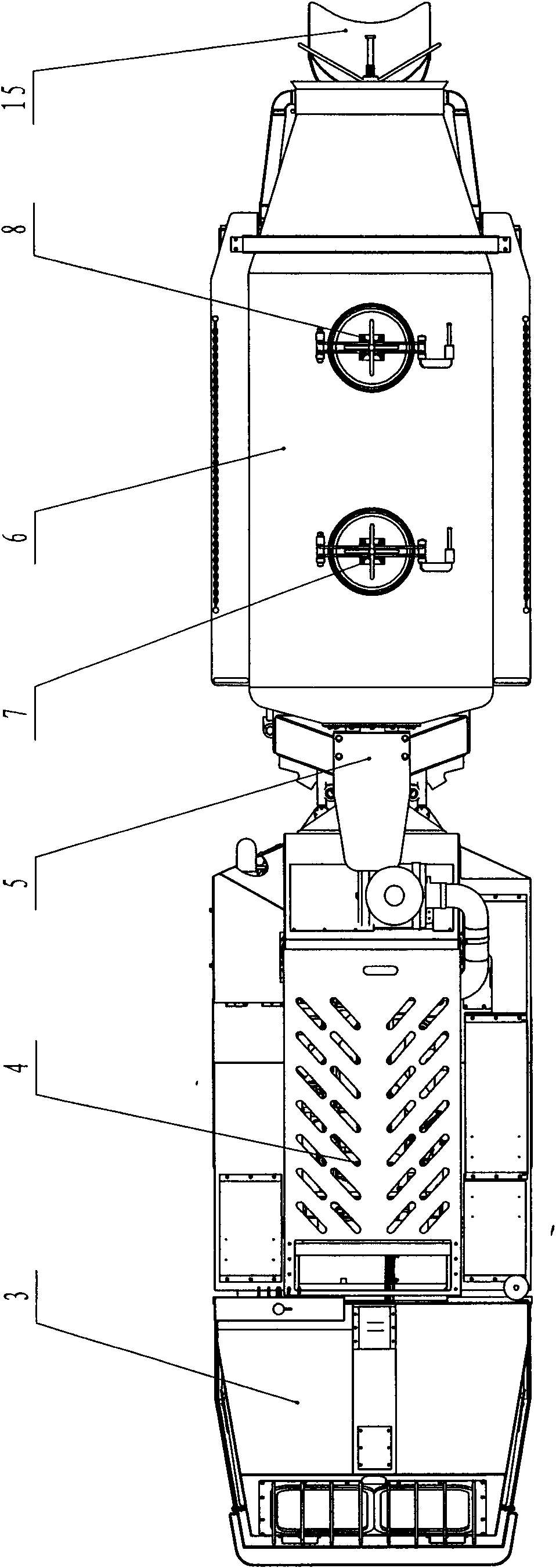

Concrete mixing and transporting car

The invention discloses a concrete mixing and transporting car which mainly and structurally comprises a front rack, a rear rack, a cab, an anti-explosion diesel motor, a twisted frame, a mixing pot, feeding ports, a discharge port, a planetary gearbox, front wheels, rear wheels, a diesel box, and a hydraulic oil tank, wherein the diesel motor is designed as being high in power and anti-explosion, so as to adapt to a severe environment underground; two feeding ports of the mixing pot enable the feeding speed to be increased; the inner wall of the mixing pot is designed as spiral linear bladesso as to enable the mixing and the discharging of a concrete flat pot to be quicker, more uniform, and cleaner; the feeding ports and the discharge port are in conical surface seal, thus being simpleand stable; a seat of the cab can be rotated laterally, thus enhancing the steering view and the comfort; and the car is advanced and reasonable in design, convenient for use, and safe, stable and reliable, and is a very ideal anti-explosion concrete mixing and transporting car underground.

Owner:TAIYUAN INST OF CHINA COAL TECH & ENG GROUP +1

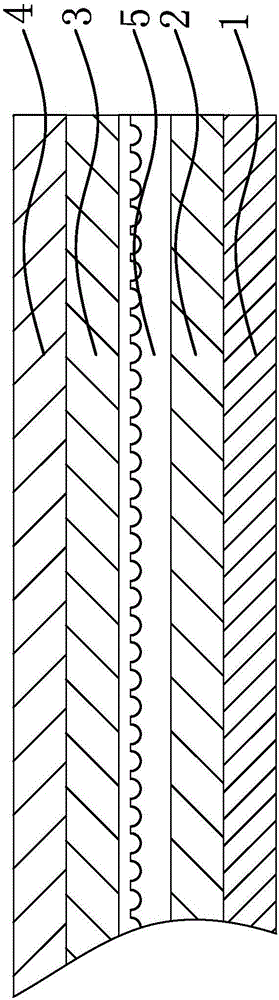

Antiradiation coating fabric and drying device thereof

The invention provides an antiradiation coating fabric and a drying device thereof, belongs to the technical field of fabrics and solves the problem of poor antiradiation effect of the fabric in the prior art. The antiradiation coating fabric comprises base cloth, wherein the front side of the base cloth is provided with a first waterproof layer, a second waterproof layer and a flame retardant layer from bottom to top; an antiradiation layer is also arranged between the first waterproof layer and the second waterproof layer; the antiradiation layer comprises antiradiation layer bottom cloth and an antiradiation shielding net; the antiradiation shielding net is formed by longitudinally and transversely staggering a plurality of antiradiation yarns; a plurality of bulges are also arranged on the antiradiation shielding net; a plurality of grooves matched with the bulges are also formed in the bottom cloth; the bulges are positioned in the grooves. The drying device of the antiradiation coating fabric comprises a machine frame and a drying box arranged on the machine frame, wherein a cavity is formed in the drying box; a first separation plate and a second separation plate are transversely fixed in the cavity; a hot air box capable of generating hot air is fixed at the lower end of the first separation plate. The antiradiation coating fabric has the advantage of good antiradiation effect.

Owner:ZHEJIANG FEIHU NEW MATERIAL CO LTD

Hunting blind

A one man or two man layout hunting blind that can be folded into a compact transportable condition and that is easily assembled or deploy in the field, the layout hunting blind having a head end and a foot end with an inner frame assembly that does not extend to the foot end, the inner frame assembly including a combination of inner folding assemblies and locking sleeves that make the blind easy to deploy in the field.

Owner:NEXUS OUTDOORS INC

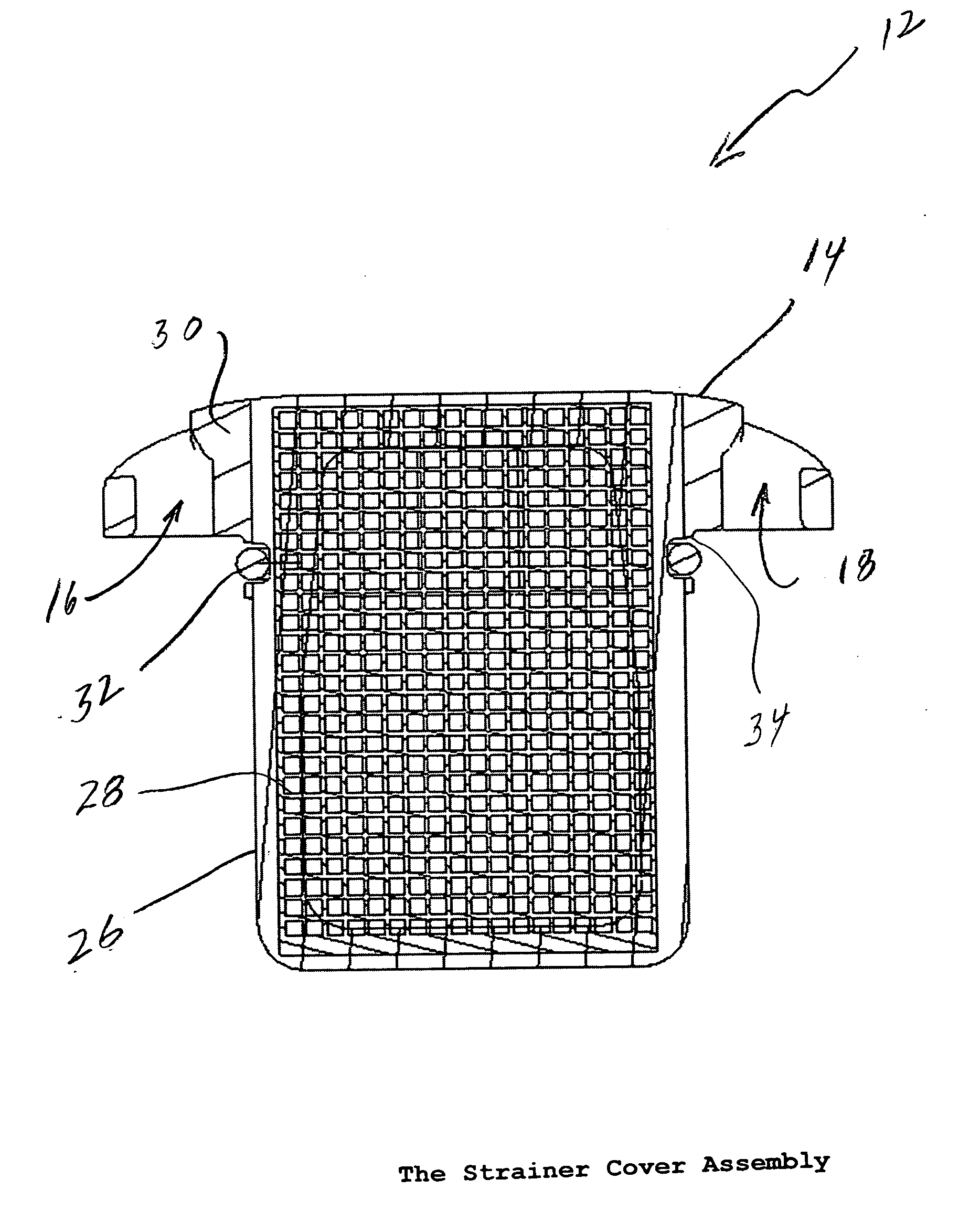

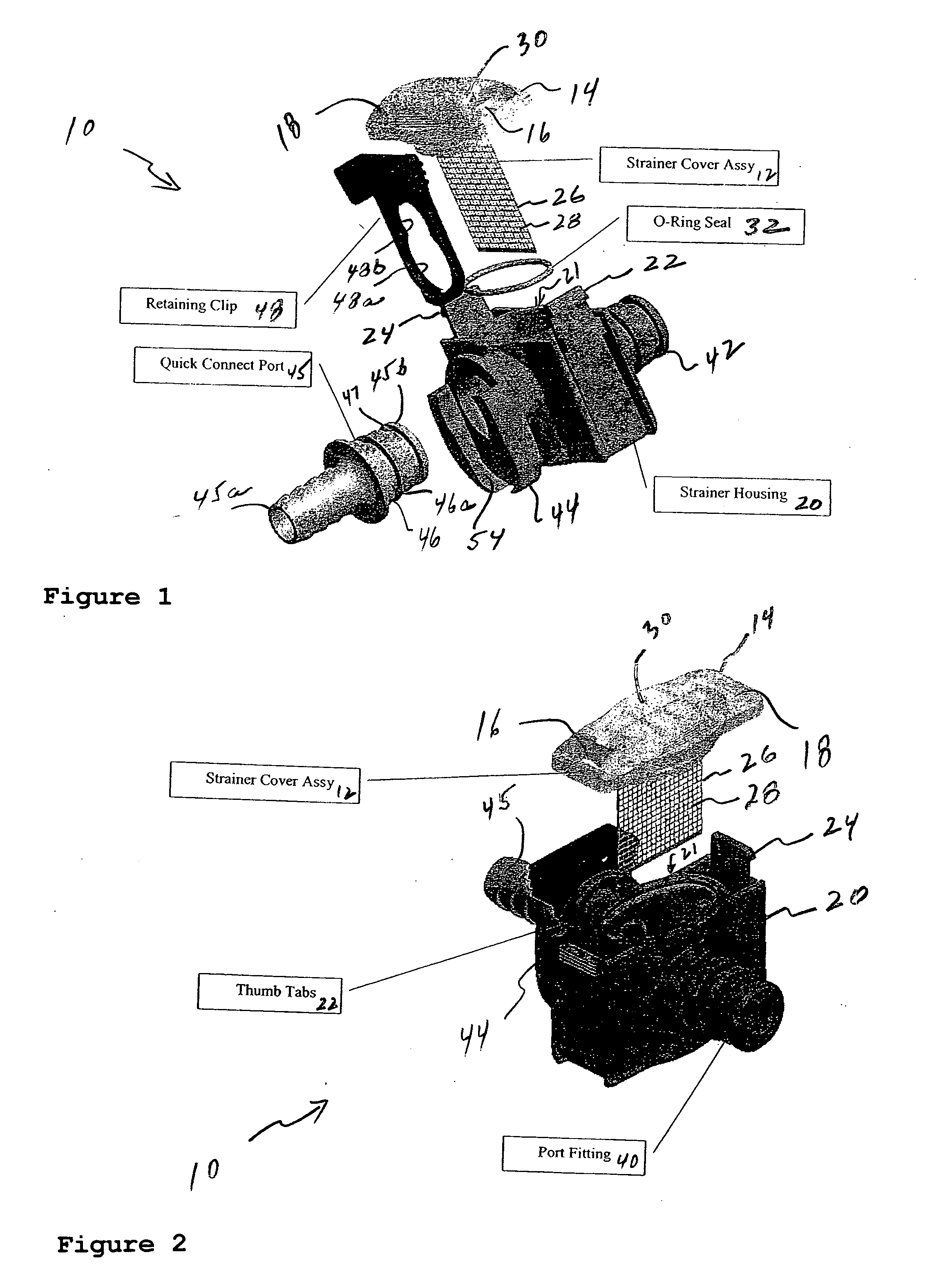

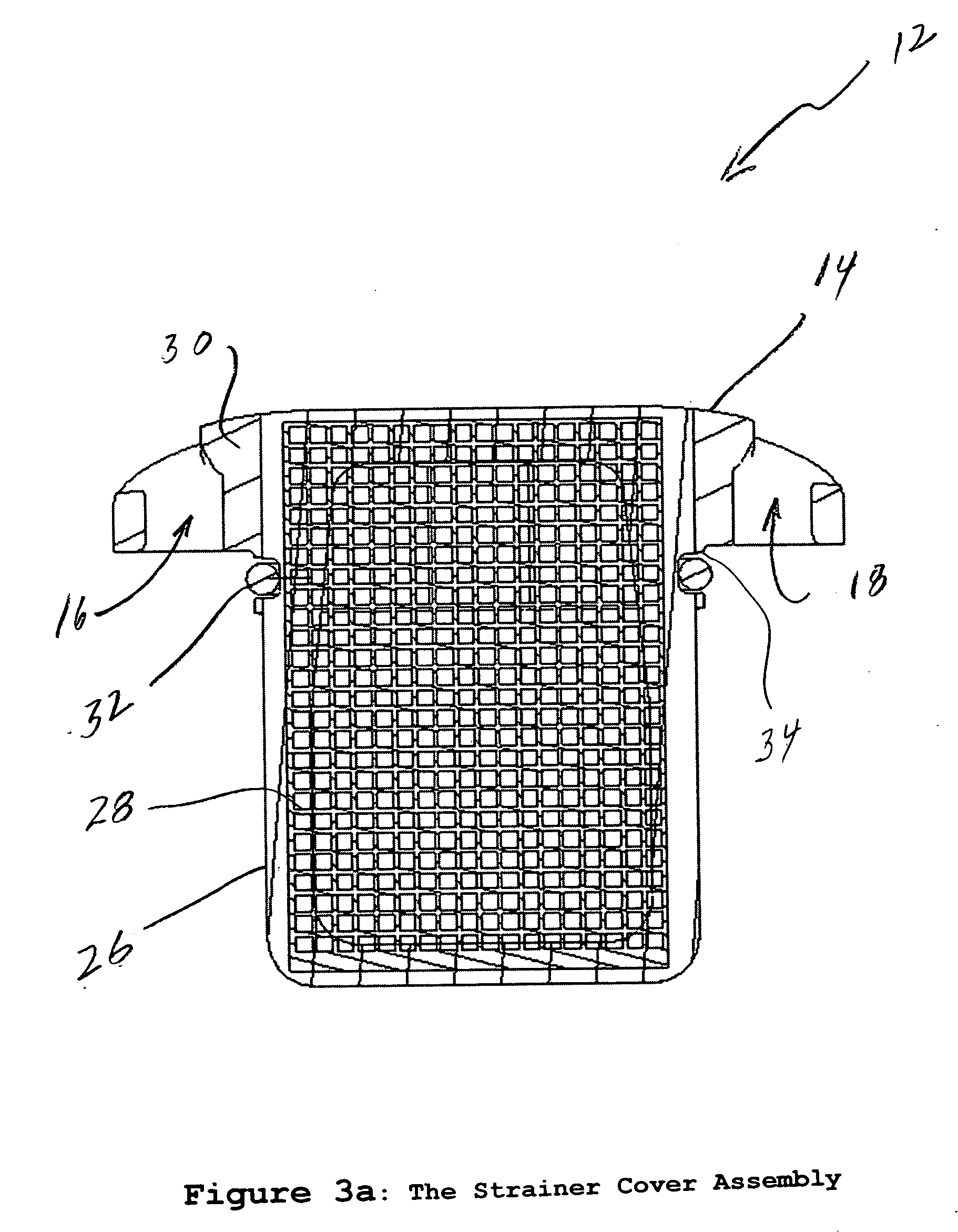

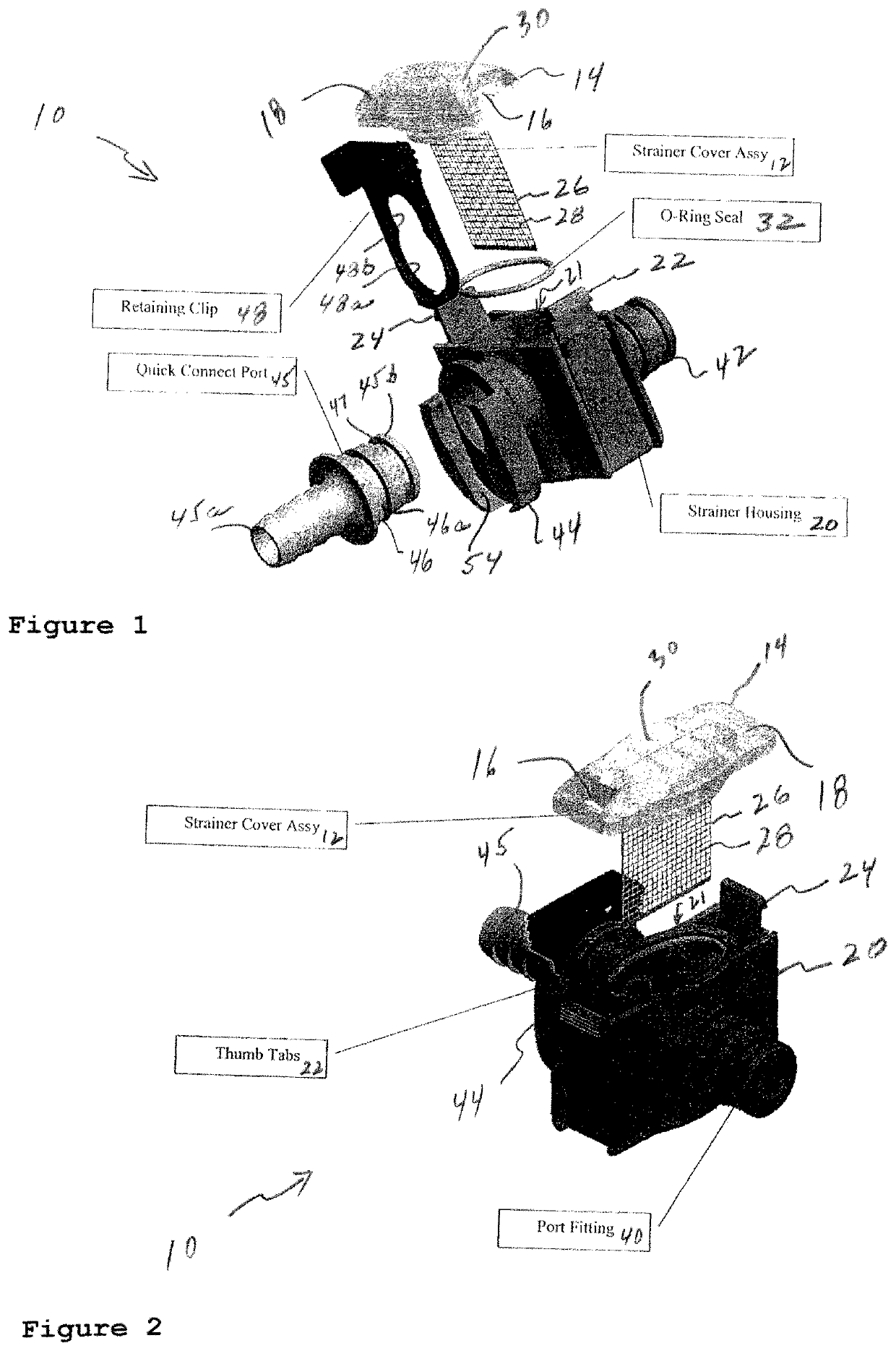

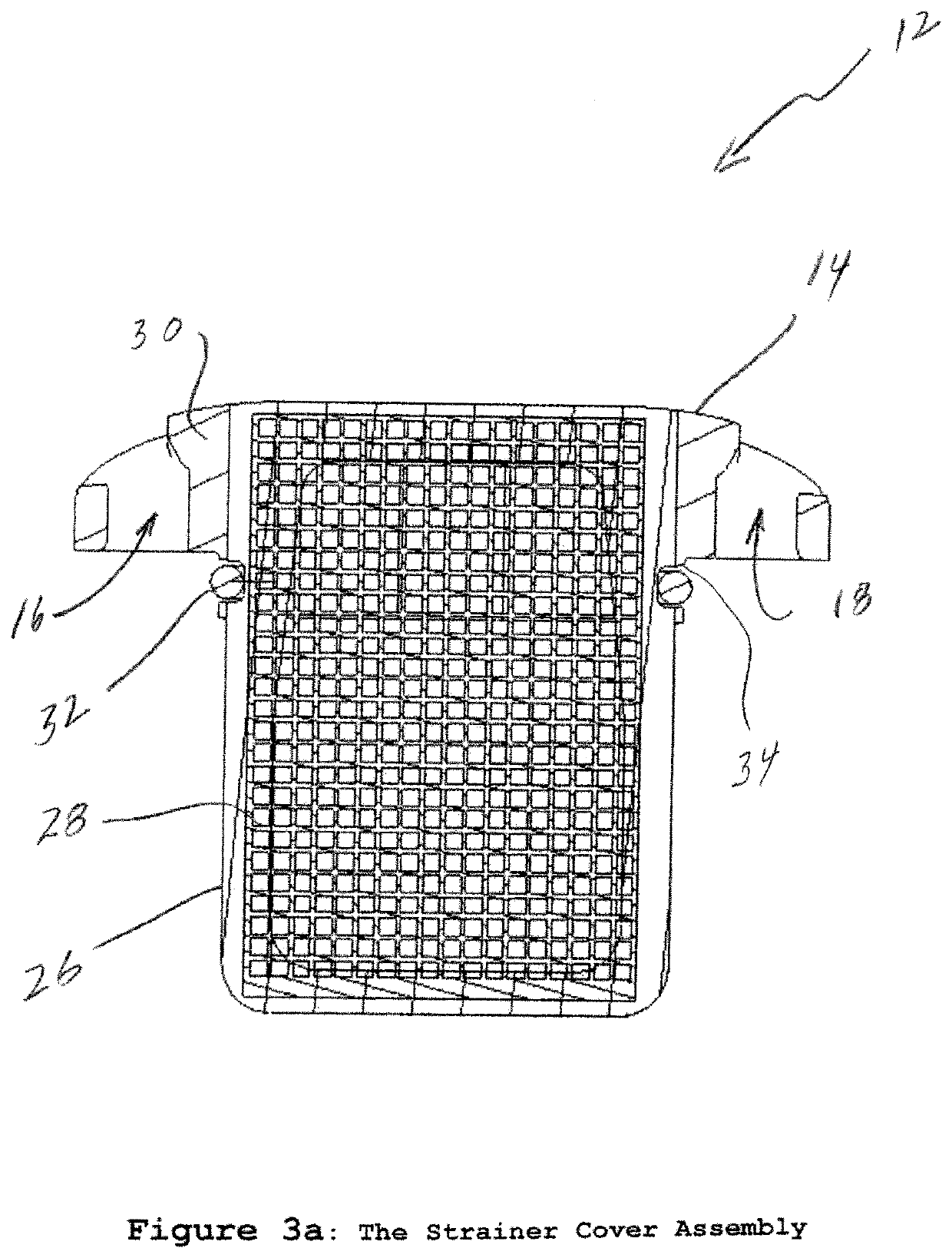

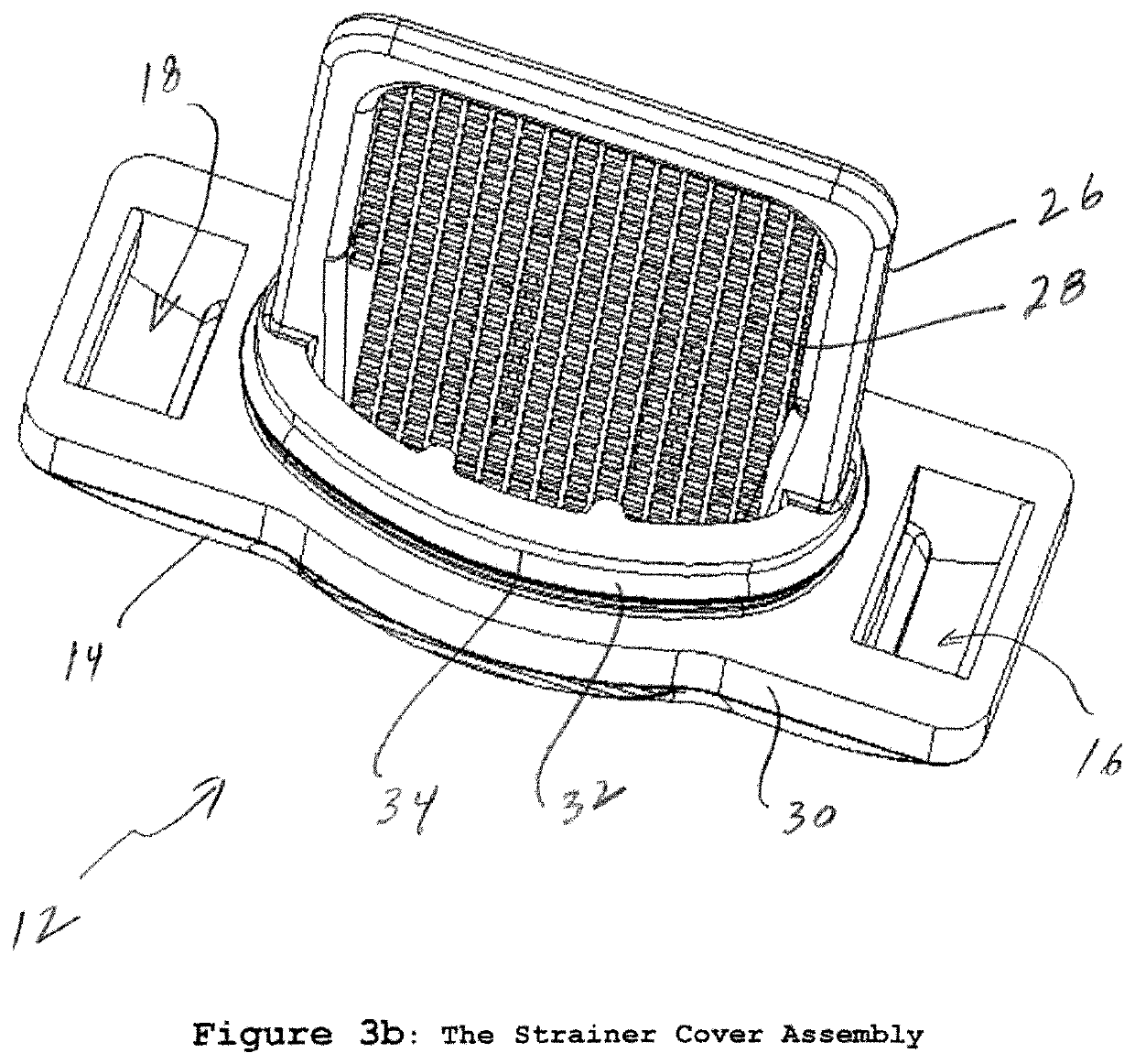

Snap on strainer with side-slide cleaning

ActiveUS20060226066A1Clean outMembrane filtersLoose filtering material filtersPlastic materialsEngineering

The present invention features a device having a strainer cover assembly having a strainer cover with tab openings, and a strainer housing having flexible tabs arranged thereon, the flexible tabs passing through the tab openings and fastening on the strainer cover with a snap action. The flexible tabs are deflected for removing the strainer cover. The strainer cover assembly includes a strainer with a screen for filtering a medium passing through the device. The snap action of the flexible tabs makes it easy to open, slide out and clean the screen on the strainer cover assembly. The strainer cover assembly and the screen may be formed as an integral unit, which helps in cleaning the screen. In operation, the user simply compresses the snap tabs and slides out the screen which is attached to the strainer cover assembly and rinses the contaminated screen while holding it by the strainer cover assembly. The integral unit being formed by plastic mold injection. The screen may be made of stainless steel material. The strainer cover assembly may be made of a clear plastic material.

Owner:XYLEM IP HLDG

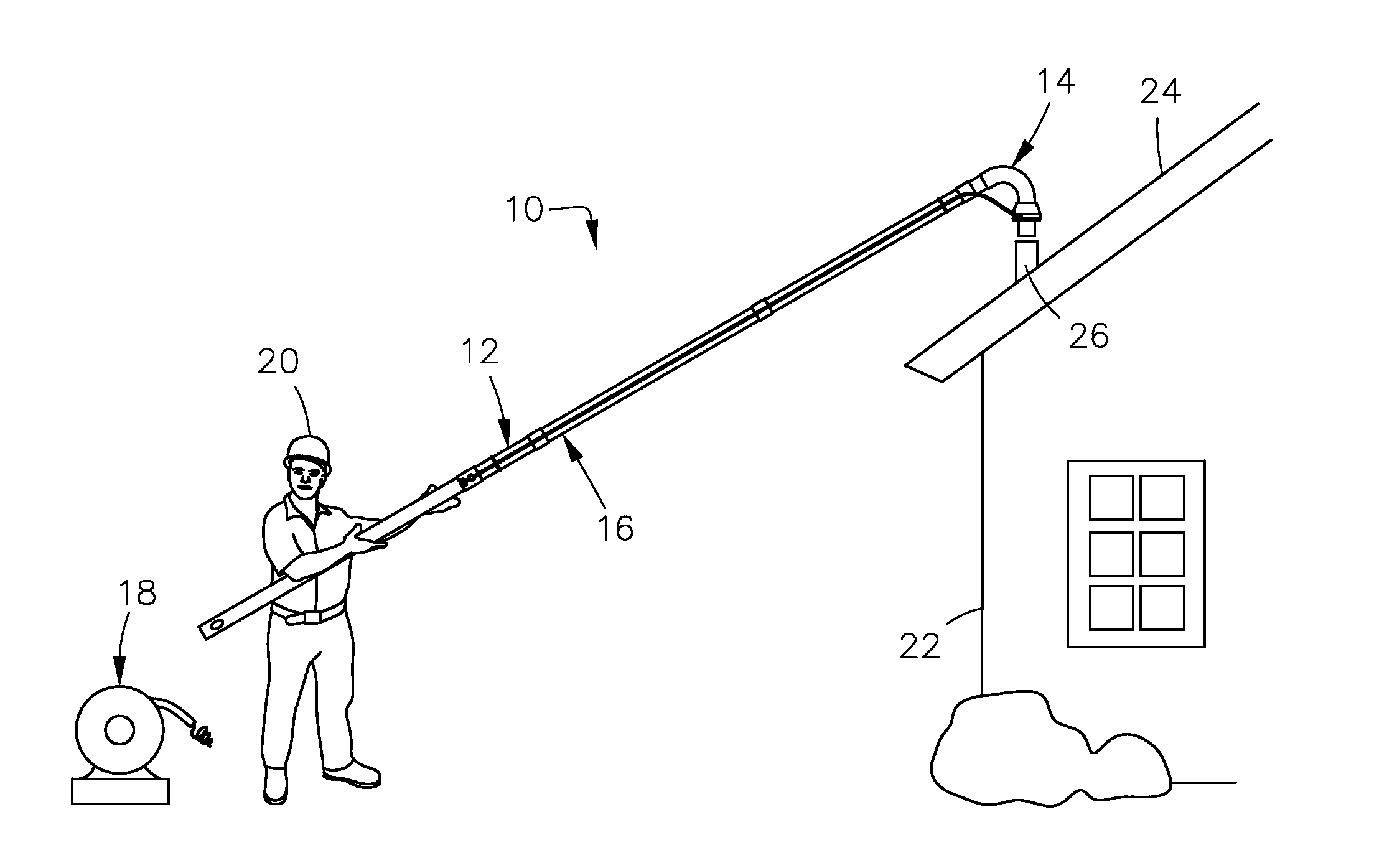

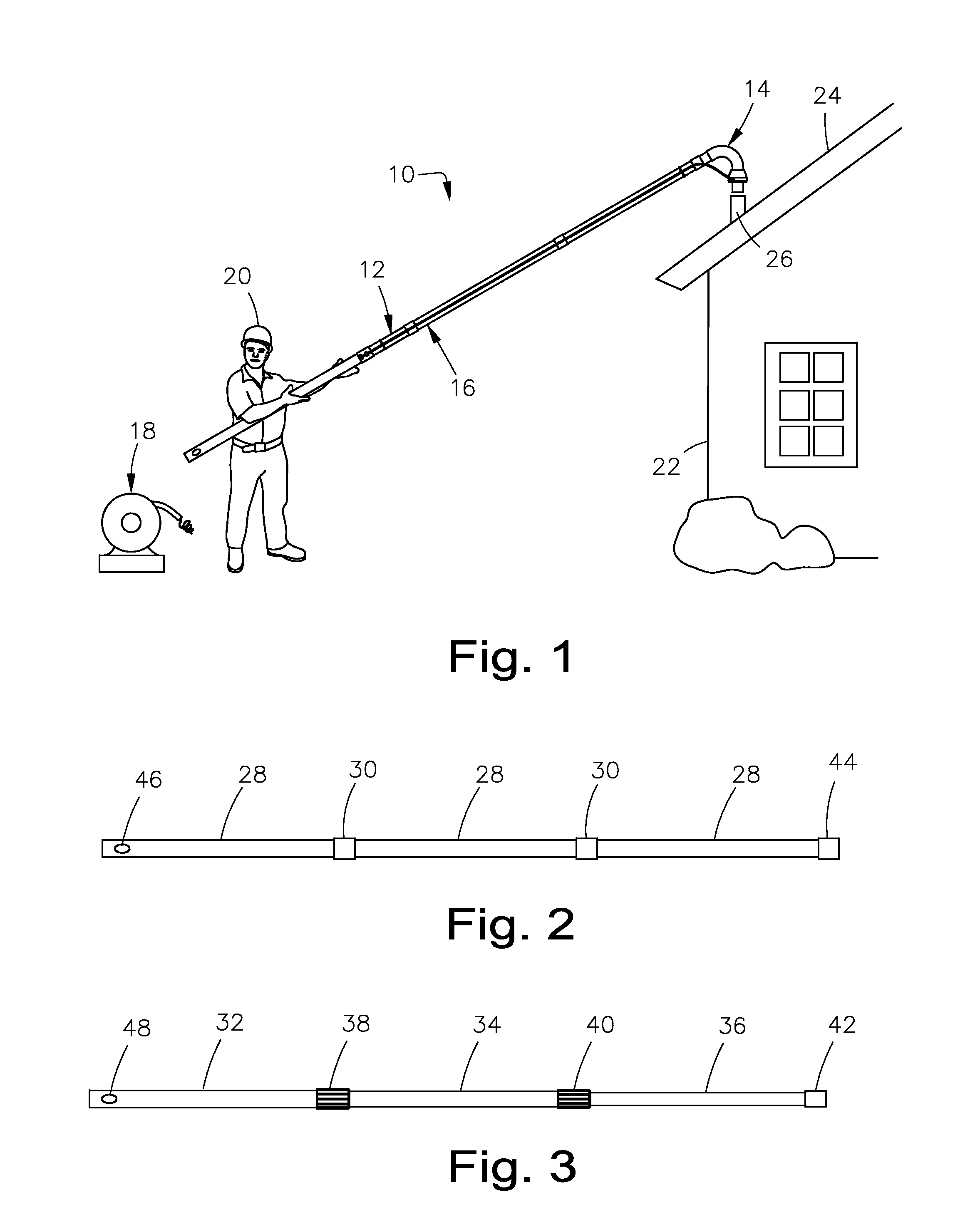

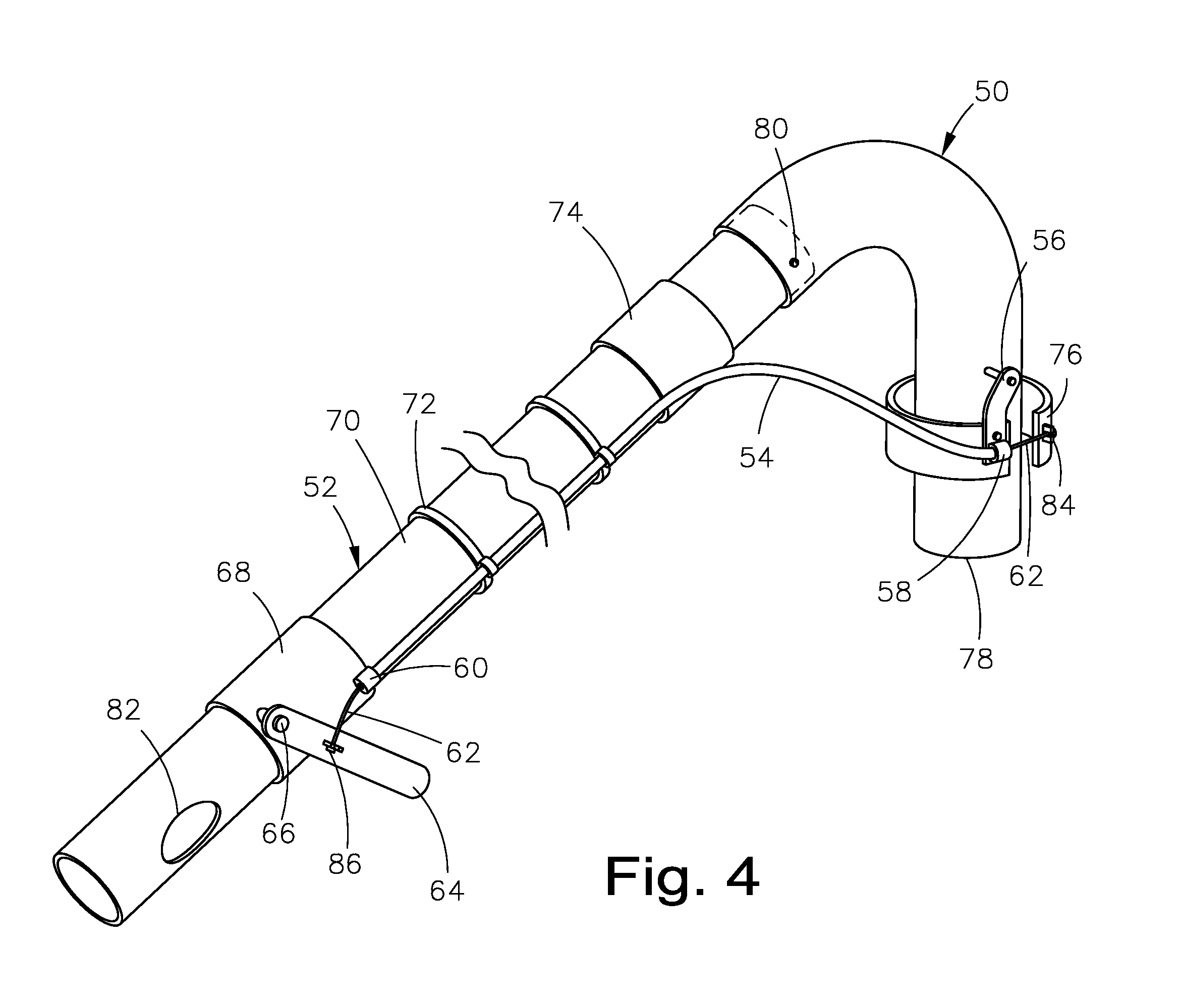

Cleanout boom

InactiveUS20150276106A1Operation is completedImprove worker safetyRoof coveringLighting and heating apparatusEngineeringMechanical engineering

Owner:LOPEZ LUIS F +1

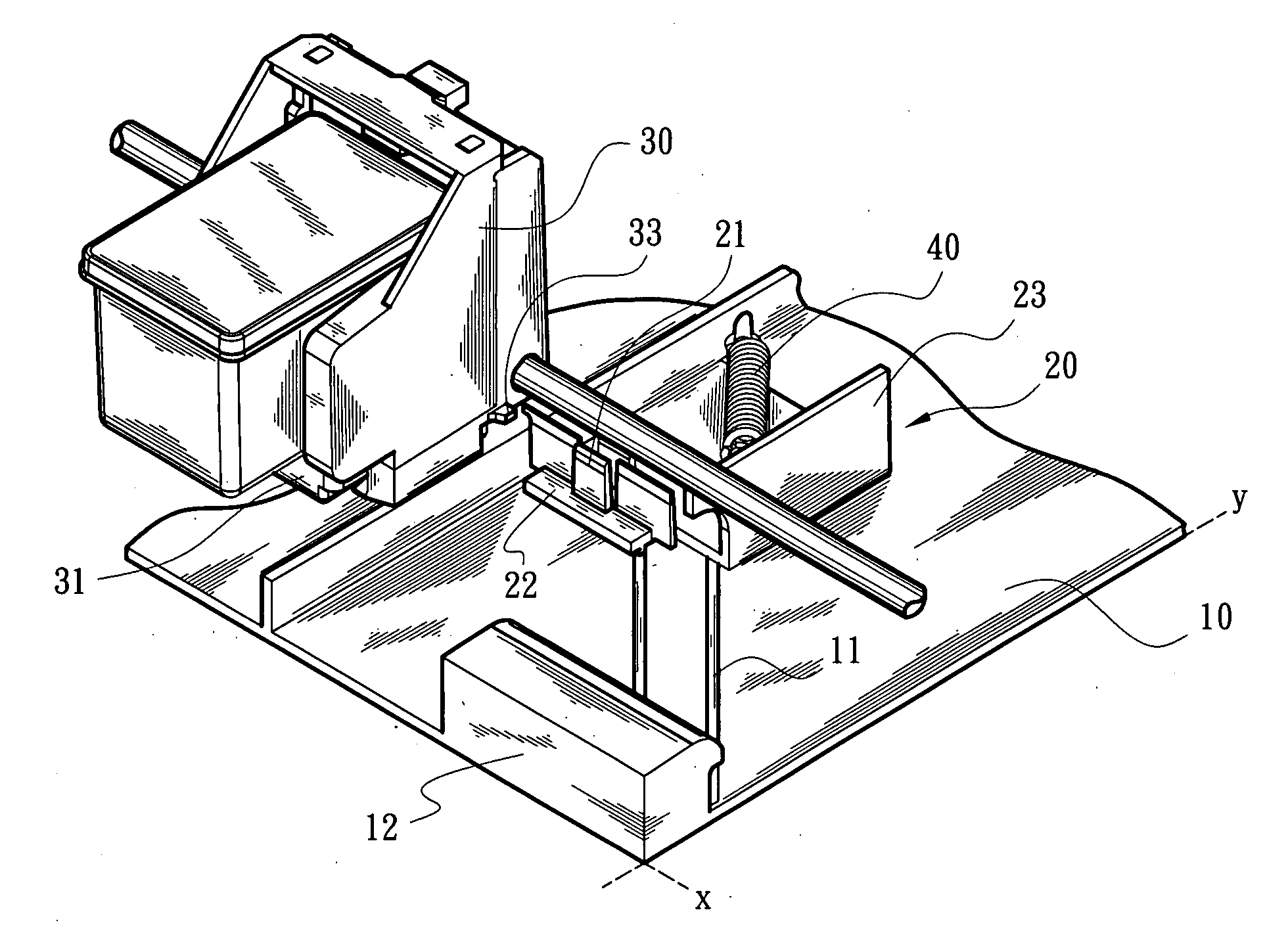

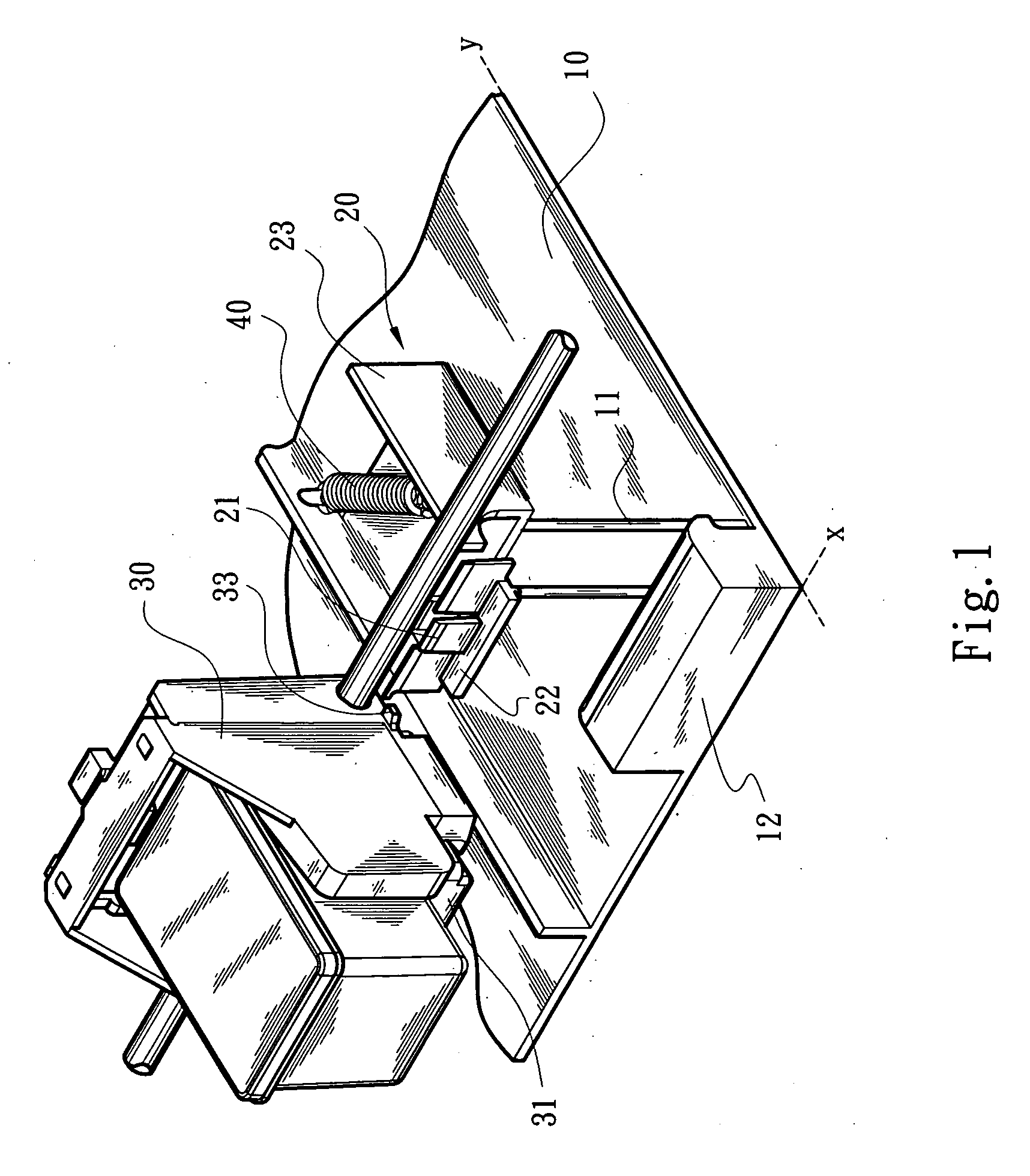

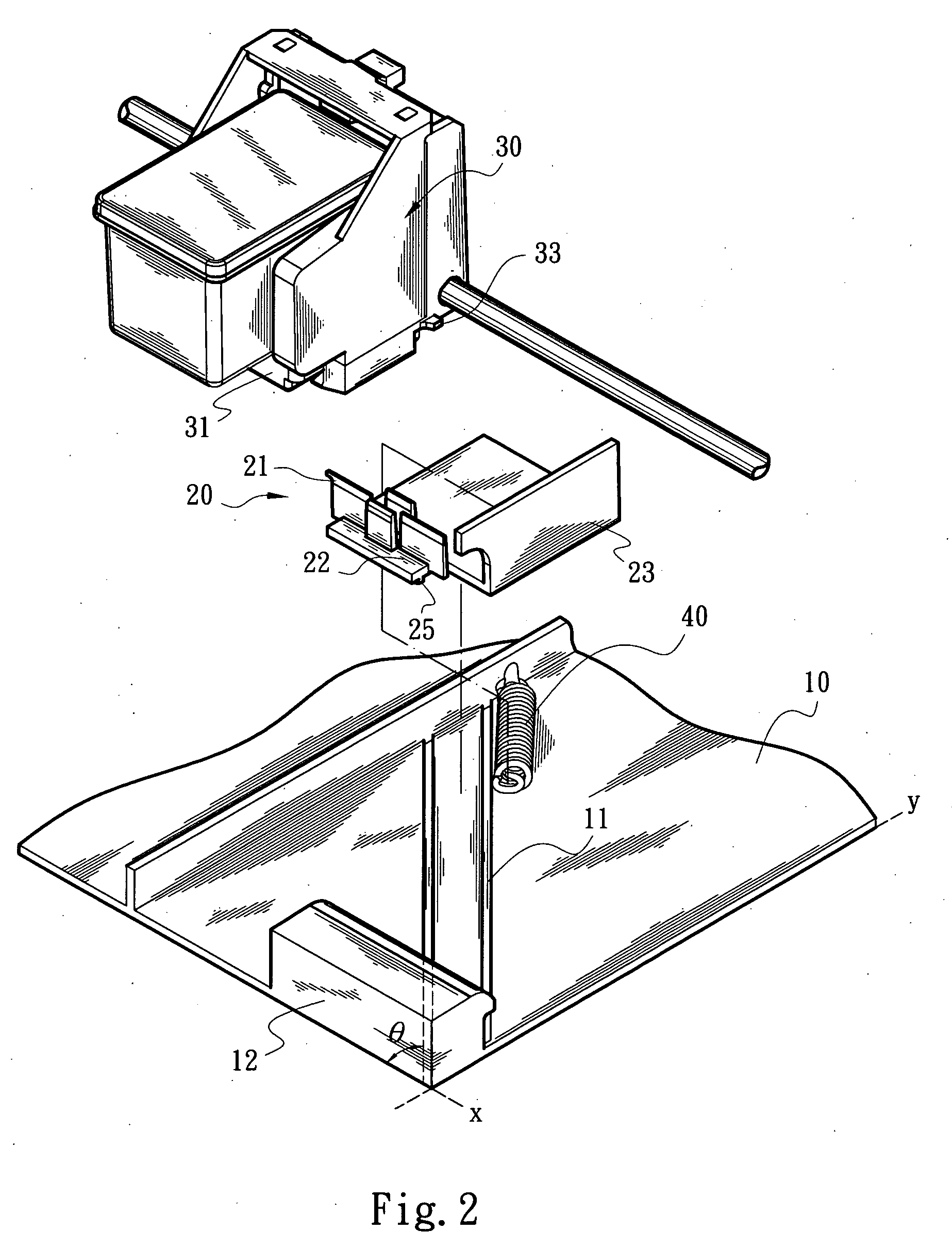

Device for cleaning out residual ink

A device for cleaning out residual ink. The device includes an assembly of a bed and a slide mount. The bed has an oblique rail. The slide mount is equipped with a wiping blade. The slide mount is drivable by an ink cartridge carrier to reciprocally move along the oblique rail on the bed. Accordingly, the wiping blade can move componentially along y-axis to wipe off residual ink remaining on a printhead of the ink cartridge.

Owner:KINPO ELECTRONICS

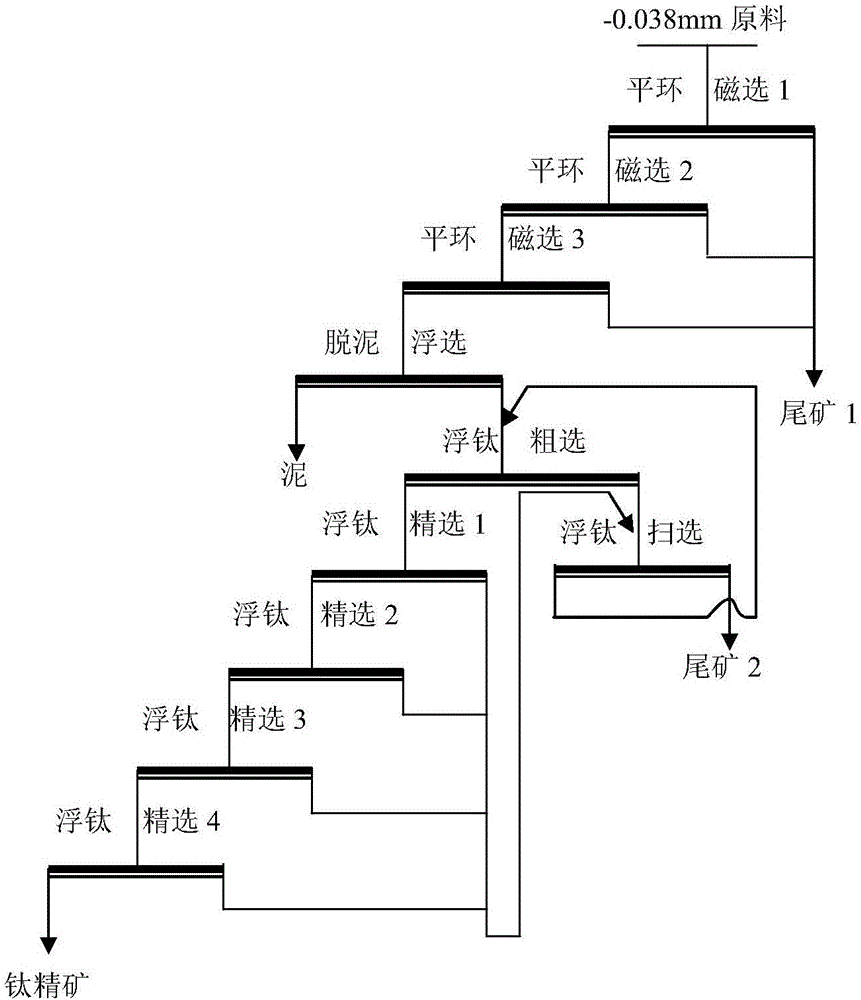

Method for obtaining ultrafine grained titanium concentrate

The invention discloses a method for obtaining ultrafine grained titanium concentrate. The method comprises the steps that 0.038 mm ilmenite materials serve as raw materials; horizontal ring magnetic separating, desliming by flotation, floating titanium roughing and floating titanium selection are sequentially conducted; and the ultrafine grained titanium concentrate with the TiO2 grade at 47%-48.5% is finally obtained, wherein the granularity of the ultrafine grained titanium concentrate is not larger than 0.038 mm. According to the method for obtaining the ultrafine grained titanium concentrate, ultrafine grained materials of 0.038mm grained ilmenite are effectively recycled, the ultrafine grained titanium concentrate with the TiO2 grade at 47%-48.5% is also obtained, and the recovery rate reaches 70% or above.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Snap on strainer with side-slide cleaning

ActiveUS11273393B2Clean outMembrane filtersLoose filtering material filtersPlastic materialsEngineering

Owner:XYLEM IP HLDG

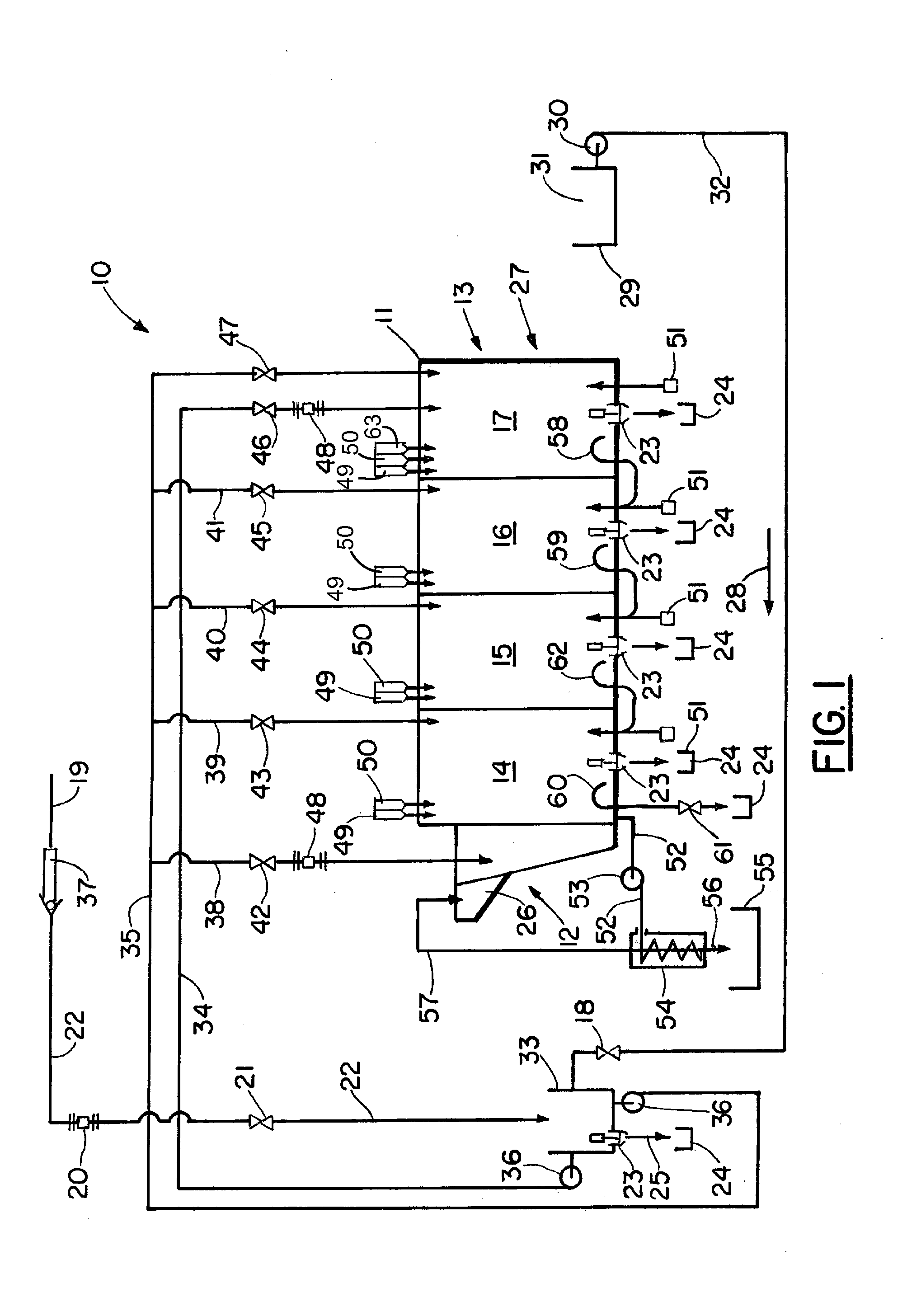

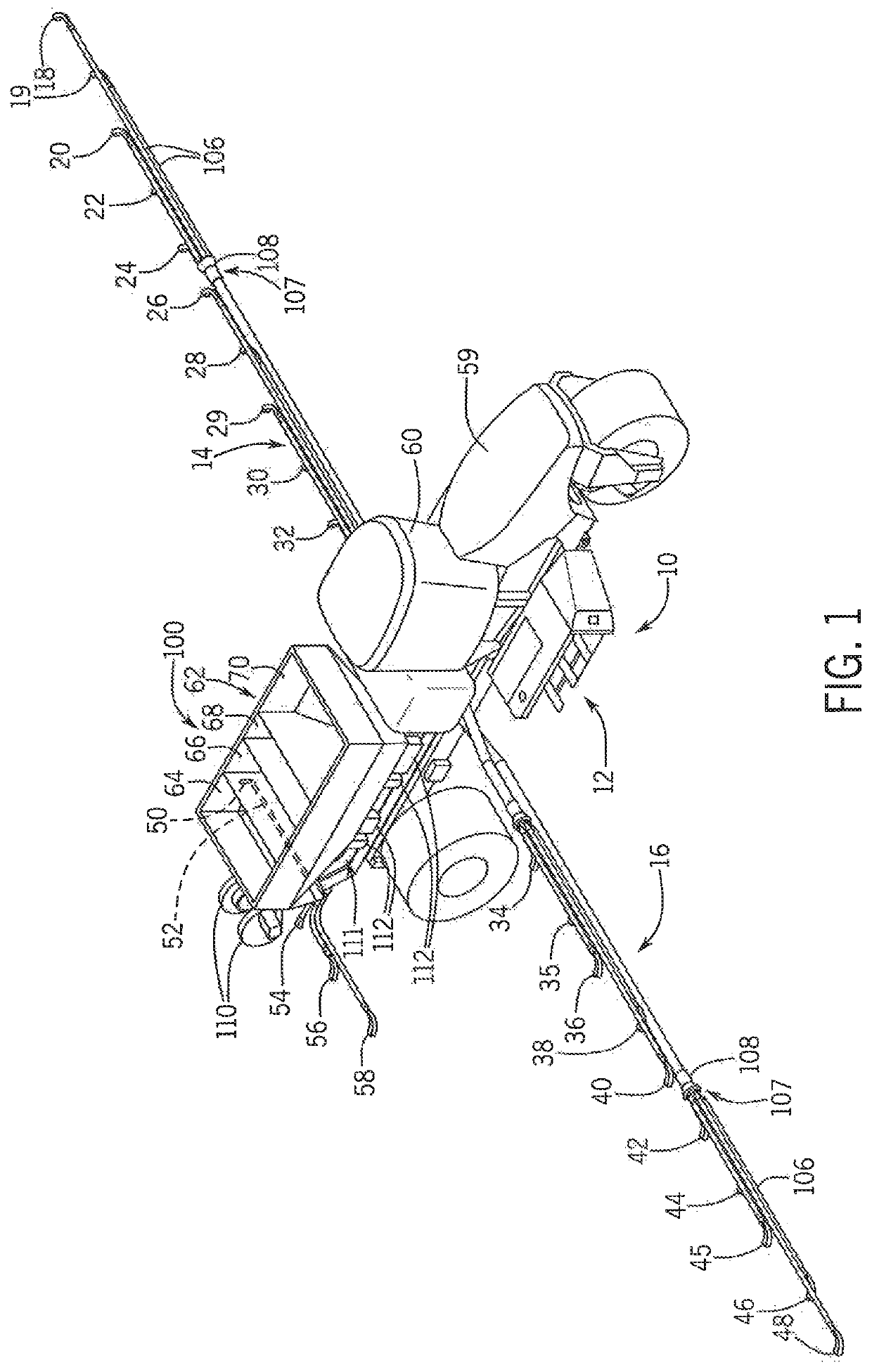

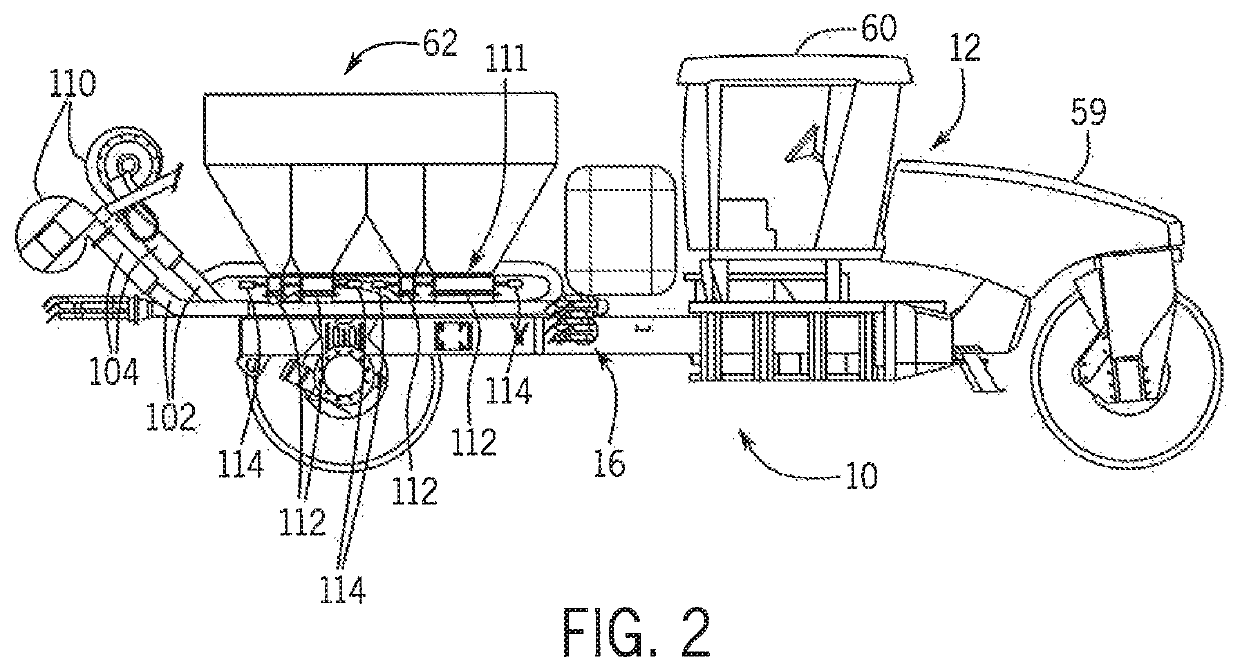

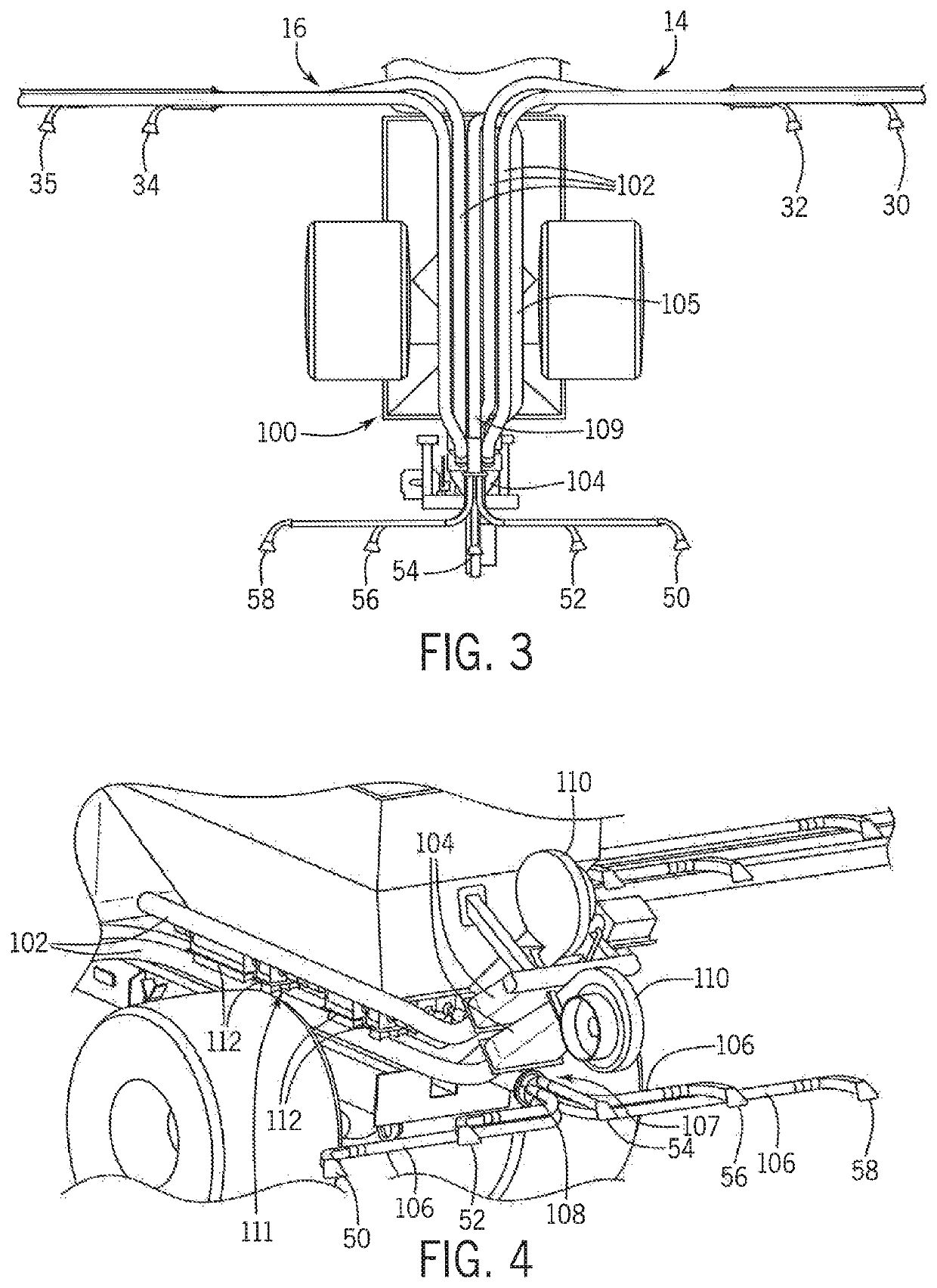

Air-assisted agitation for tanks of application equipment

ActiveUS10687460B2Reduce formationClean outFertiliser distributersMixer accessoriesProcess engineeringDelivery system

Owner:CNH IND CANADA

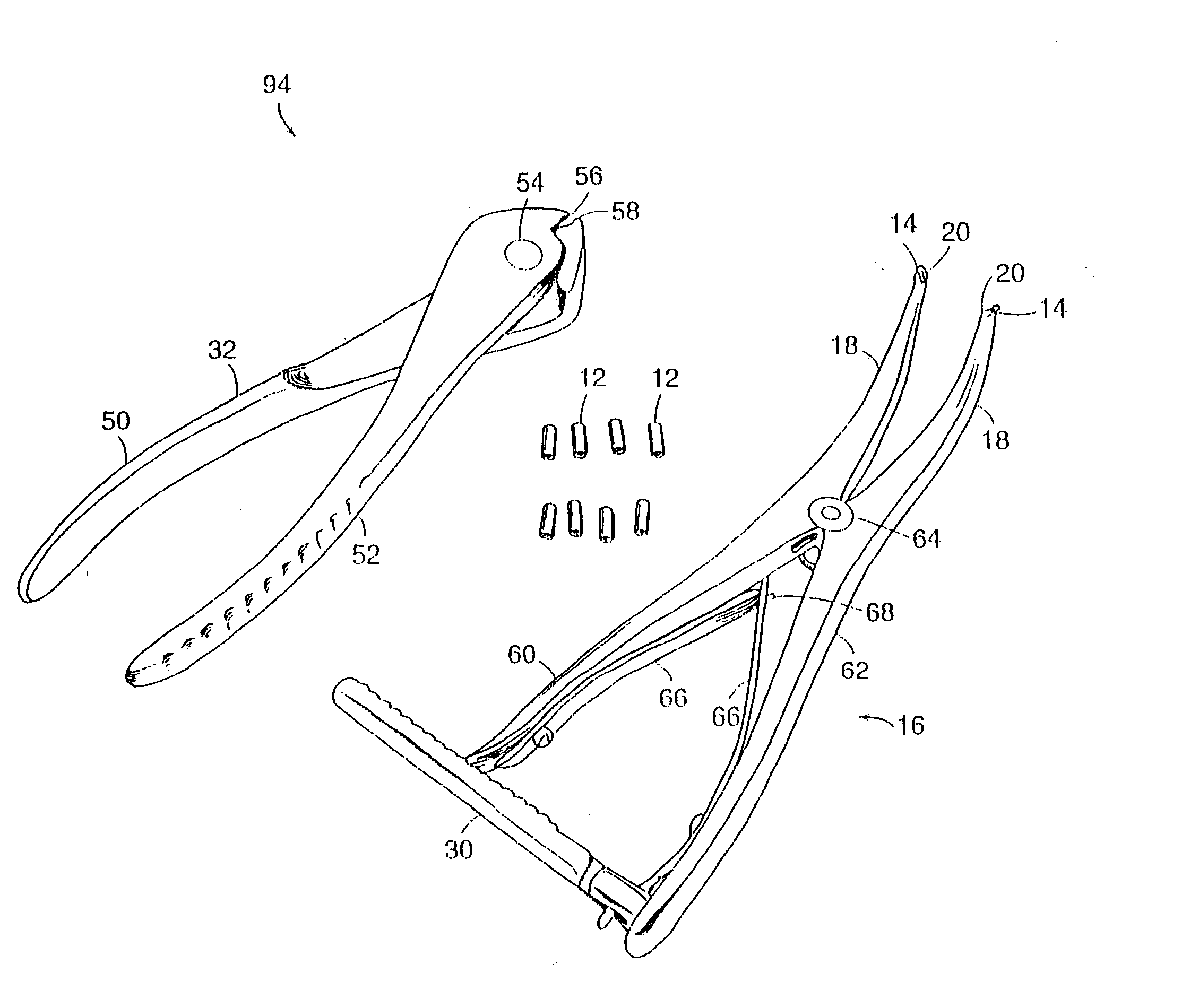

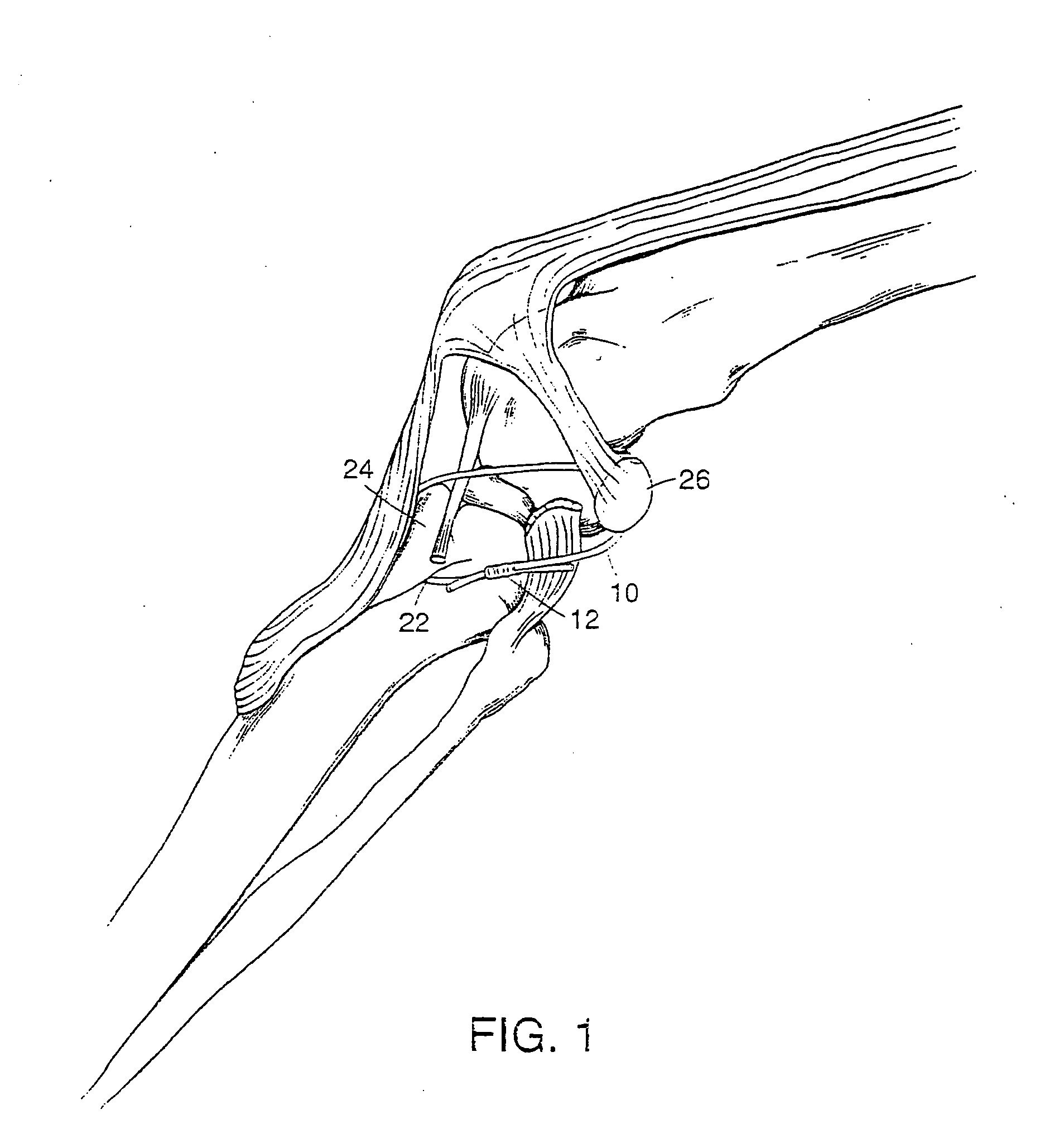

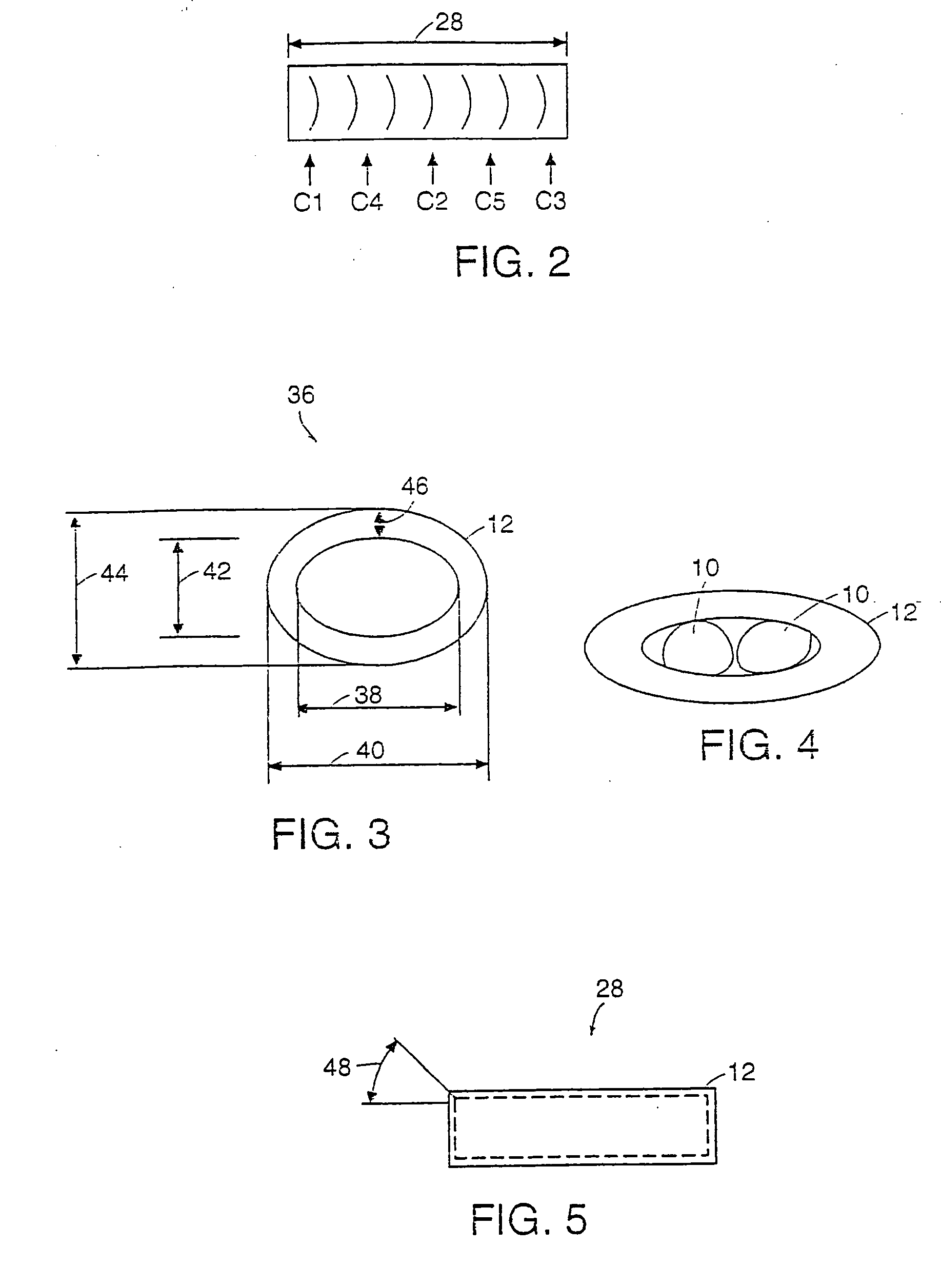

Crimping device for cranial cruciate ligament stabilization

InactiveUS20090248063A1Maintain tensionLow elongationSuture equipmentsPliersCruciate ligamentLigament structure

A crimp tube crimping system including a crimping tool having: a first arm having a proximal end and a distal end, the proximal end comprising a first handle and the distal end comprising a first jaw, a second arm having a proximal end and a distal end, the proximal end comprising a second handle and the distal end comprising a second jaw, the second arm hingedly connected to the first arm, a first straight, flat crimping member integral with the first jaw of the first arm, the first crimping member having a first inner surface width, and a second straight, flat crimping member integral with the second jaw of the second arm, the second crimping member having a second inner surface width, the first and second straight, flat crimping members defining a gap therebetween when the first and second handles close and the crimping tool is in a fully closed position about the crimp tube, the first and second inner surface widths limiting further deformation of the crimp tube, the flat crimping members preventing cutting of a suture within the crimp tube.

Owner:WOTTON III HARRY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com