Microelectrolytic treatment process of printing and dyeing waste water

A technology for treating process, printing and dyeing wastewater, applied in textile industry wastewater treatment, return water treatment, multi-stage water treatment, etc. Effect of SS concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

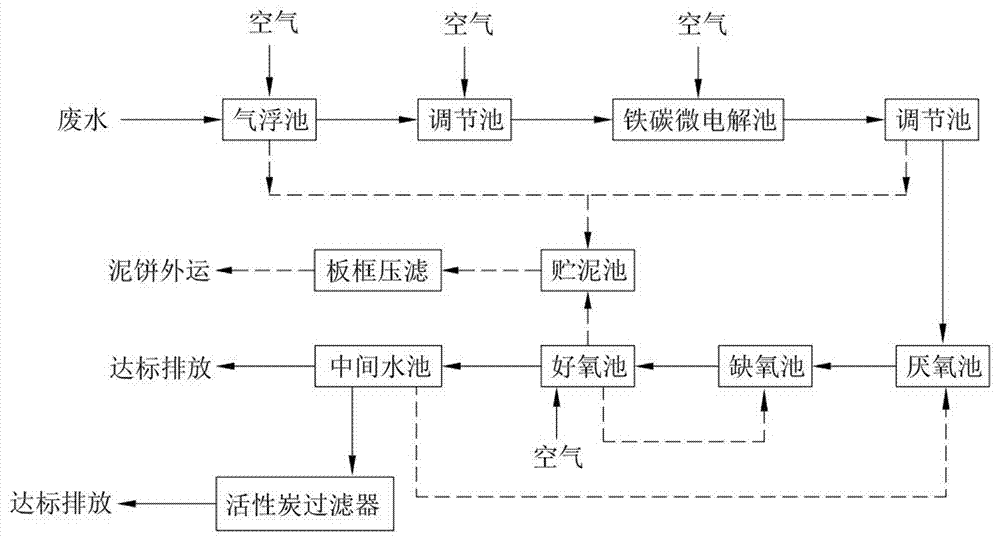

[0031] Such as figure 1 As shown, a micro-electrolysis treatment process of printing and dyeing wastewater is carried out according to the following steps:

[0032] (1) Wastewater pretreatment:

[0033] A. Air flotation treatment: After the wastewater from each workshop is collected, it is pumped to the air flotation tank, and at the same time, air is introduced into the air flotation tank to perform air flotation treatment on the wastewater to remove suspended matter in the water. The residence time of the wastewater in the air flotation tank is 2 hours;

[0034] B. Conditioning treatment: the effluent of the air flotation tank is lifted to the regulating tank by a pump, the wastewater is pre-acidified, and perforated aeration pipes are arranged in the regulating tank.

[0035] Perforated aeration is carried out in the regulating tank, and the wastewater is stirred and homogenized. The residence time of the wastewater in the regulating pond is 36 hours, and the effluent of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com