Pretreatment method of lignocellulose by using microwave-assisted alkaline sodium sulfite

A technology of lignocellulose and sodium sulfite, which is applied in the field of biomass resource utilization and comprehensive utilization of agricultural waste, can solve the problems of ineffective removal of lignin, destruction of active ingredients, excessive alkali consumption, etc., and achieve good enzymatic hydrolysis effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

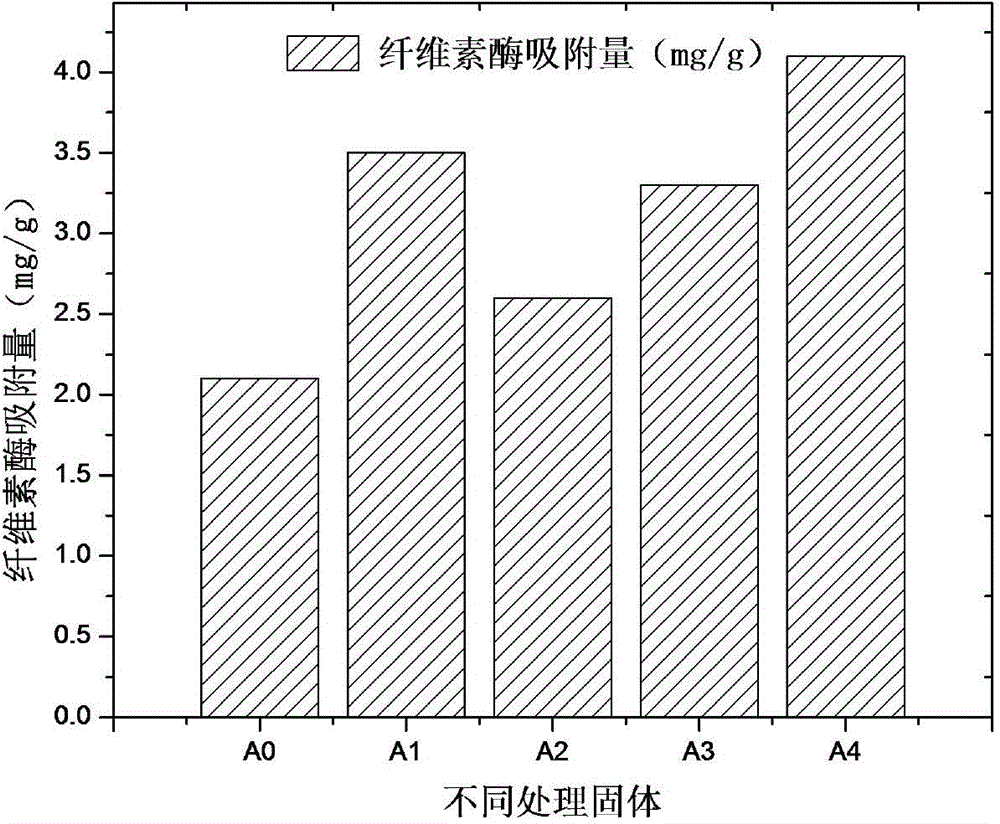

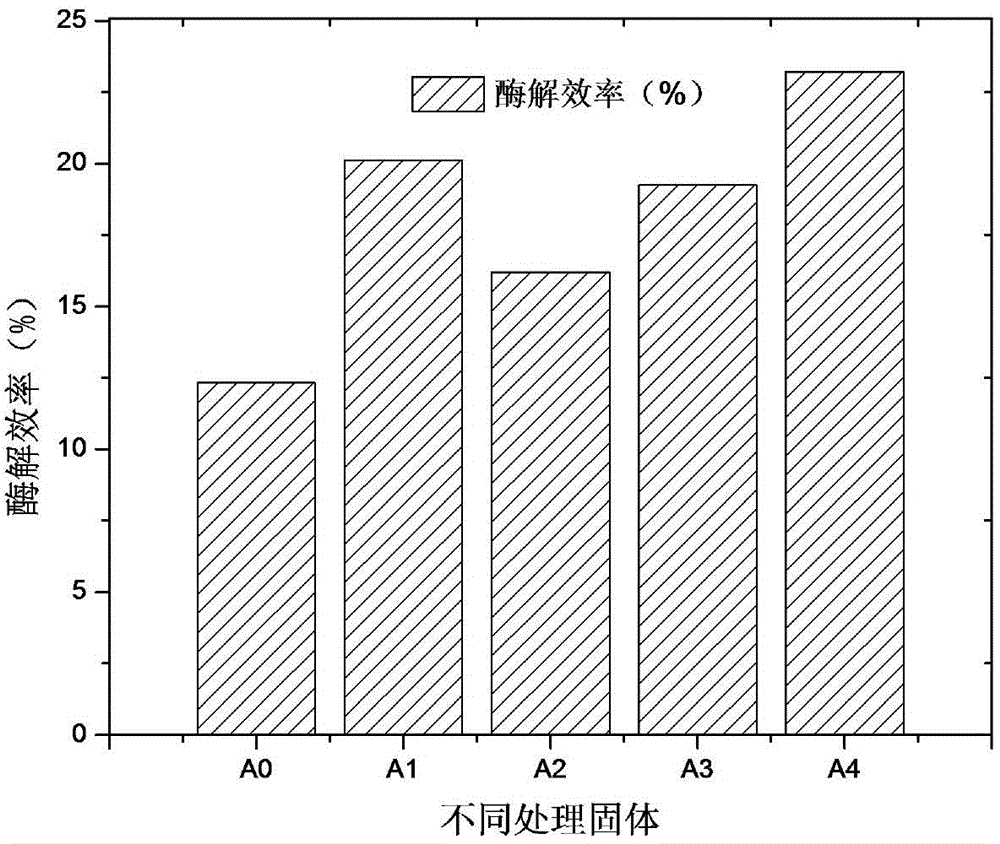

[0022] Embodiment 1 sodium hydroxide chemical treatment lignocellulose

[0023] The method for chemically treating lignocellulose with sodium hydroxide comprises the following steps: adding 10 g of wheat straw raw materials passed through a 40-mesh sieve into 80 mL of sodium hydroxide solution, wherein the concentration of NaOH is 2%, and then treating at 120° C. for 30 minutes. After treatment, cool to room temperature, and separate the solid and liquid by centrifugation. First, wash once with sodium hydroxide solution, and then wash with deionized water until the pH of the filtrate reaches neutrality. The filter residue obtained from solid-liquid separation was placed in an oven at 60° C., and the drying time was 9 hours. The mass of the dry matter was weighed to calculate the material yield. The resulting solids were treated as substrates for cellulase adsorption assays and enzymatic degradation reactions.

Embodiment 2

[0024] Example 2 Traditional alkaline sodium sulfite treatment of lignocellulose

[0025] The traditional method for processing lignocellulose with alkaline sodium sulfite comprises the following steps: adding 10 g of wheat straw raw material through a 40-mesh sieve into 80 mL of alkaline sodium sulfite solution, wherein Na 2 SO 3 The concentration of NaOH is 2%, the concentration of NaOH is 0.05%, and then treated in a reactor at 100°C for 20min. After treatment, cool to room temperature, and separate the solid and liquid by centrifugation. First, wash once with alkaline sodium sulfite solution, and then wash with deionized water until the pH of the filtrate reaches neutrality. The filter residue obtained from solid-liquid separation was placed in an oven at 60° C., and the drying time was 9 hours. The mass of the dry matter was weighed to calculate the material yield. The resulting solids were treated as substrates for cellulase adsorption assays and enzymatic degradation ...

Embodiment 3

[0026] Example 3 Microwave-assisted alkaline sodium sulfite treatment of lignocellulose

[0027] Utilize the lignocellulose processing method of the present invention technology, comprise the steps: join in the 80mL alkaline sodium sulfite solution of the wheat straw raw material 10g that crosses 40 mesh sieves, wherein Na 2 SO 3 The concentration of NaOH is 2%, and the concentration of NaOH is 0.05%. Microwave-assisted treatment is carried out, and the microwave power is constant at 300W. In a single cycle, the microwave working time is 2 minutes, the intermittent time is 1 minute, and the working time is 10 cycles, with a total time of 30 minutes. After microwave treatment, the solid-liquid separation was carried out by centrifugation. First, it was washed once with alkaline sodium sulfite solution, and then washed with deionized water until the pH of the filtrate reached neutrality. The filter residue obtained from solid-liquid separation was placed in an oven at 60° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com