Processing process for threshing, re-drying and classifying tobacco stems

A processing technology, a technology of re-cured tobacco, applied in the field of sorting and processing technology of threshing and red-cured tobacco stems, which can solve the problem of not considering the impact of stem pressing strength on stem quality, not considering the appearance of tobacco stem formula stem form, not taking into account Problems such as the impact of tobacco stem pressing on quality, to achieve the effect of submitting work efficiency and economic benefits, saving storage and storage costs, and improving pretreatment effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

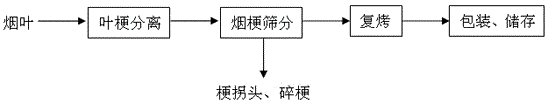

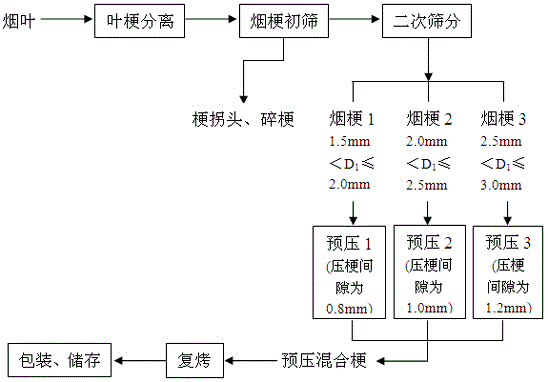

[0025] A sorting and processing technology for threshing and redrying tobacco stems, comprising the following steps:

[0026] (1) Separation of leaves and stems: after the leaves are threshed, the leaves and stems are separated, and the moisture content of the tobacco stems is controlled to be about 18%;

[0027] (2) Preliminary screening of tobacco stems: the tobacco stems obtained in step (1) are screened to remove stems and broken stems, and the broken stems are tobacco stems with a length not greater than 10 mm and a diameter not greater than 1.5 mm;

[0028] (3) Secondary screening: the tobacco stems obtained from the primary screening in step (2) are screened by a multi-layer vibrating sieve to obtain three types of tobacco stems, and the diameters of the three types of tobacco stems are respectively recorded as D 1 、D 2 and D 3 , 1.5 mm 1 ≤2.0mm, 2.0mm2 ≤2.5mm, 2.5mm3 ≤3.0 mm;

[0029] (4) Classified pre-pressing: pre-press the three types of tobacco stems obtained i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com