Formation method for lithium ion battery and lithium ion battery

A lithium-ion battery and a formation method technology, applied in the field of formation of lithium-ion batteries, can solve the problems of unsuitable formation methods of lithium-ion batteries, unsatisfactory electrochemical performance of lithium-ion batteries, etc. The effect of excellent performance and excellent cycle performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

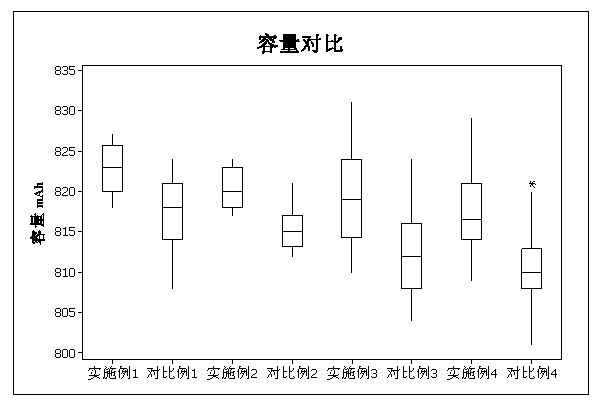

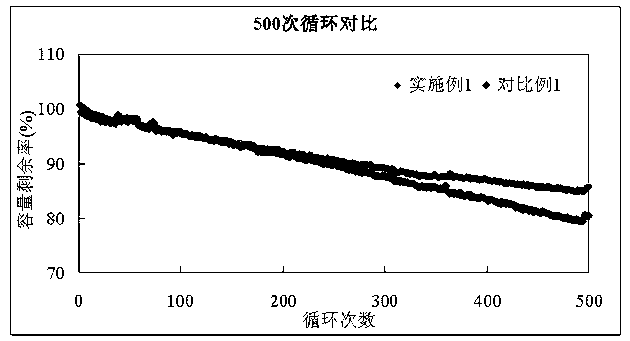

Embodiment 1

[0059] This embodiment 1 contains two kinds of cathode materials, LiMn 2 o 4 and LiFePO 4 Mix and make positive electrode material, the design charge capacity of positive electrode material is 800mAh, of which LiMn 2 o 4 400 mAh, LiFePO 4 It is 400mAh; Natural graphite is negative pole, and diaphragm material is polyethylene film, adopts the chemical conversion method of the present invention to carry out chemical conversion, specifically comprises the following steps:

[0060] 1. Production of battery:

[0061] A. Production of positive electrode sheet: Calculate the positive electrode active material LiMn according to the design capacity 2 o 4 and LiFePO 4 The amount of the positive electrode material is as follows: 93wt% of the positive electrode active material, 2wt% of the conductive agent, 3wt% of PVDF, and then use NMP as a solvent to make a slurry and apply it on the Al foil. After drying, Positive electrode sheets are made by rolling and other processes;

...

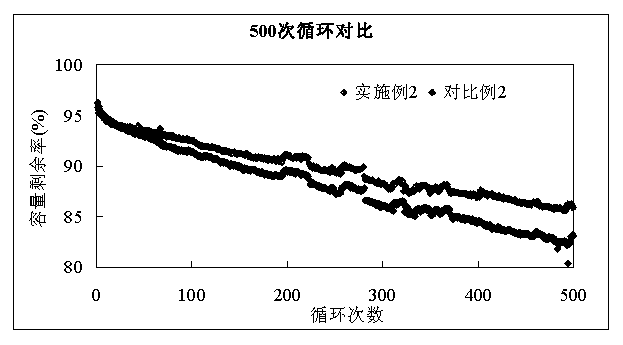

Embodiment 2

[0070] This Example 2 contains two kinds of cathode materials, LiCoO 2 and LiFePO 4 Mix and make positive electrode material, the design charging capacity of positive electrode material is 800mAh, of which LiCoO 2 400 mAh, LiFePO 4 It is 400mAh; Natural graphite is negative electrode, and diaphragm material is polypropylene film, adopts the chemical formation method of the present invention to carry out chemical formation, specifically comprises the following steps:

[0071] 1. Production of battery:

[0072] A. Production of positive electrode sheet: Calculate the positive electrode active material LiCoO according to the design capacity 2 and LiFePO 4 The amount of the positive electrode material is as follows: 90wt% positive electrode active material, 5wt% conductive agent, 5wt% PVDF, and then use NMP as a solvent to make a slurry and coat it on the Al foil. After drying, Positive electrode sheets are made by rolling and other processes;

[0073] B, the making of neg...

Embodiment 3

[0081] This embodiment 3 contains two kinds of cathode materials, LiNiO 2 and LiFePO 4 Mix and make positive electrode material, the design charge capacity of positive electrode material is 800mAh, among which LiNiO 2 600 mAh, LiFePO 4 It is 200mAh; Natural graphite is negative electrode, and diaphragm material is polyethylene film, adopts the chemical formation method of the present invention to carry out chemical formation, specifically comprises the following steps:

[0082] 1. Production of battery:

[0083] A. Production of positive electrode sheet: Calculate the positive electrode active material LiNiO according to the design capacity 2 and LiFePO 4 The amount of the positive electrode material is as follows: 95wt% positive electrode active material, 1wt% conductive agent, 4wt% PVDF, and then use NMP as a solvent to make a slurry and coat it on the Al foil. After drying, Positive electrode sheets are made by rolling and other processes;

[0084] B, the making of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com