A method of preparing high-efficiency adsorption material from paraffin oil decolorization waste soil and its application

An adsorption material, paraffin oil technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc. Active groups, the effect of improving physical and chemical adsorption properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

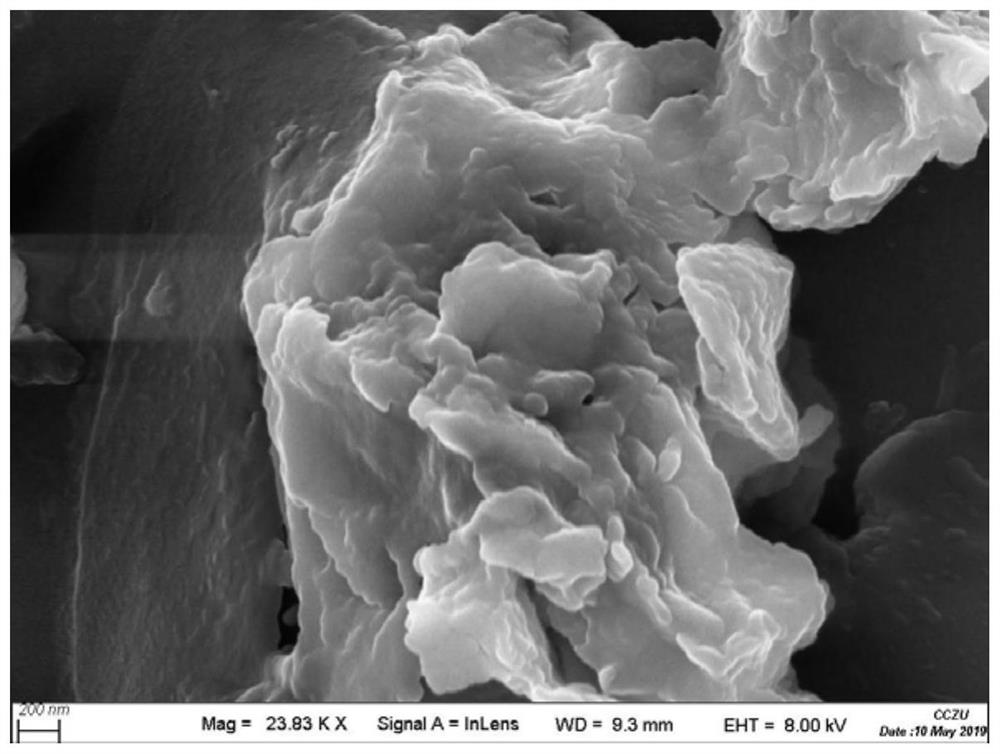

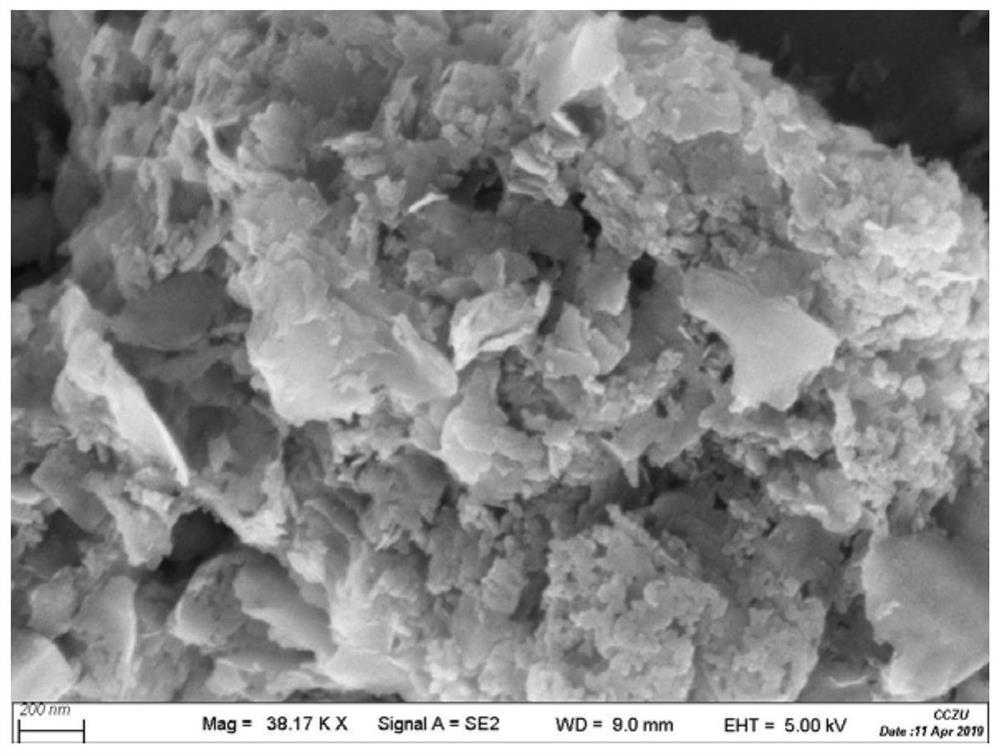

Image

Examples

Embodiment 1

[0016] 1. Put 5.0 kg of paraffin oil decolorization waste soil in a tube furnace, raise the temperature to 650 °C at a heating rate of 10 °C / min under a nitrogen atmosphere, and keep it at this temperature for 1.0 hours to obtain a clay / carbon composite Material;

[0017] 2. Take 1.0 kg of clay / carbon composite material and quickly add it to 10.0 kg of diammonium hydrogen phosphate solution with a mass percent concentration of 15% for quenching. After 4 days of immersion, filter, and place the obtained filter cake in a nitrogen atmosphere at 500 ° C. Keep warm for 1.0 hour to prepare clay / carbon porous adsorption material.

Embodiment 2

[0019] 1. Put 5.0 kg of paraffin oil decolorization waste soil in a tube furnace, raise the temperature to 450 °C at a heating rate of 20 °C / min under a nitrogen atmosphere, and keep it at this temperature for 4.0 hours to obtain a clay / carbon composite Material;

[0020] 2. Take 1.0 kg of clay / carbon composite material and quickly add it to 3.3 kg of diammonium hydrogen phosphate with a concentration of 25% by mass to quench it. After soaking for 2 days, filter it, and place the obtained filter cake in a nitrogen atmosphere at 400°C. After 2.0 hours of heat preservation, the clay / carbon porous adsorption material is obtained.

Embodiment 3

[0022] 1. Put 5.0 kg of paraffin oil bleaching waste soil in a tube furnace, raise the temperature to 550 °C at a heating rate of 15 °C / min under a nitrogen atmosphere, and keep it at this temperature for 2.5 hours to obtain a clay / carbon composite Material;

[0023] 2. Take 1.0 kg of clay / carbon composite material and quickly add it to 5.0 kg of diammonium hydrogen phosphate with a concentration of 20% by mass to quench it. After soaking for 3 days, filter it, and place the obtained filter cake in a nitrogen atmosphere at 450°C. After 1.5 hours of heat preservation, the clay / carbon porous adsorption material is obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com