Nitrogen-doped formed biochar as well as preparation method and application thereof

A technology of nitrogen doping and biochar, applied in the direction of separation methods, chemical instruments and methods, carbon compounds, etc., can solve the problems of lack of high-value utilization methods, difficulty in utilization, and high environmental risks, and achieve low cost, mechanical High-strength, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

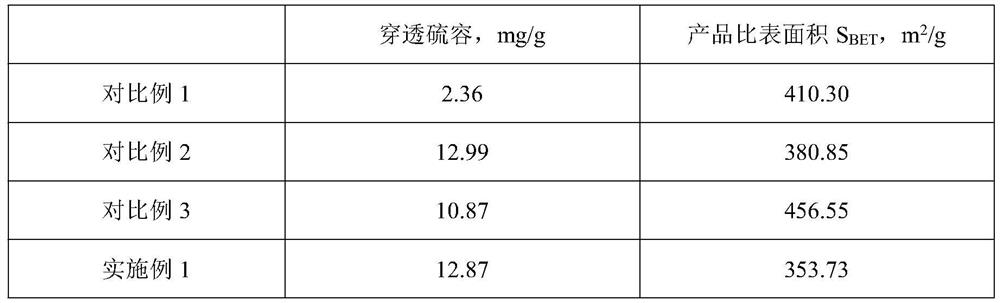

Embodiment 1

[0053] First, mix the gasification residue of brewing waste and urea at a ratio of 100:10 by weight for more than 20 minutes until uniform, then add 40 parts by weight of coal tar, and fully mix at room temperature until there is no powdery muddy aggregate, and the rest of the steps are the same as in the comparative example 1.

Embodiment 2

[0055] First, mix the sieved brewery waste gasification residue and urea at a ratio of 100:50 by weight for more than 20 minutes until uniform, then add 40 parts by weight of coal tar, and fully mix at room temperature until there is no powdery muddy aggregate, and the rest of the steps Same as Comparative Example 1.

Embodiment 3

[0057] First, mix the liquefied residue of brewing waste and melamine in the proportion of 100:10 by weight for more than 20 minutes until uniform, then add 40 parts by weight of coal tar, and fully mix at room temperature until there is no powdery mud-like agglomerate, and the rest of the steps are the same Scale 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com