Method for curing and thermal-treatment drying of cathode wet raw plate

A drying and positive electrode technology, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of difficult to stabilize the transformation of the positive electrode lead paste material crystal form, the drying time is still more than 18 hours, and the production cycle of the polar plate is elongated, so as to achieve curing. Drying, overall time reduction, strength-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

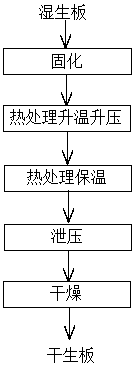

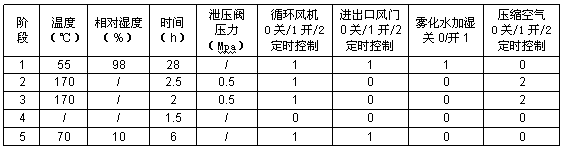

[0030] The main process of positive electrode wet raw board curing and heat treatment drying is as follows: figure 1 Shown, the concrete technical parameter of the present embodiment is as shown in table 1:

[0031] Table 1

[0032]

[0033] Step 1 curing stage: the temperature is set to 55°C, the relative humidity is set to 98%, and the time is set to 28h. The pressure relief valve and compressed air are closed, the circulating fan and atomized water humidification are turned on, the indoor pressure is at normal pressure (1atm), and the inlet and outlet dampers are under timing control.

[0034] Compressed air can also be turned on during the curing stage to ensure adequate oxygen in the curing chamber. However, since the atomized water contains compressed air, the atomization humidification process has the function of replenishing air; and when the inlet and outlet dampers are opened regularly, the moisture will be discharged from the outlet damper and the air will ente...

Embodiment 2

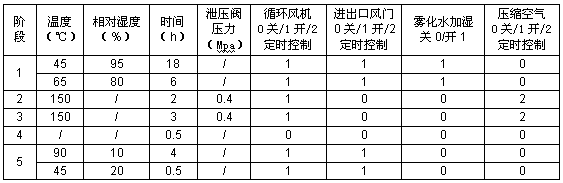

[0043] The main process of positive electrode wet raw board curing and heat treatment drying is as follows: figure 1 Shown, the concrete technical parameter of the present embodiment is as shown in table 2:

[0044] Table 2

[0045]

[0046] Step 1 Curing stage: divided into two sub-steps, the first step is to set the temperature to 45°C, the relative humidity to 95%, and the time to 18h; the second step to set the temperature to 65°C, the relative humidity to 80%, and the time to 6h. Close the pressure relief valve and compressed air, turn on the circulating fan and atomized water humidification, the indoor pressure is normal pressure (1atm), and the inlet and outlet dampers are in the timing control state.

[0047] Step 2 heat treatment heating and pressure raising stage: the temperature is set to 150°C, the opening pressure of the relief valve is set to 0.4 Mpa, and the heating time is set to 2h. During this process, the inlet and outlet dampers are closed and the ato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com