Concrete rear-planting anchoring rib construction method

A construction method and technology for anchoring bars, which are applied in building maintenance, construction, building construction, etc., can solve the problems of difficult control of construction quality, damage to concrete structures, low construction efficiency, etc. Efficiency, beneficial to construction, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0022] A method for constructing post-concrete anchor bars, comprising the following steps:

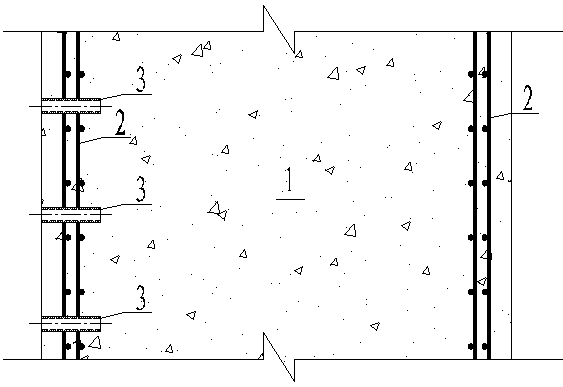

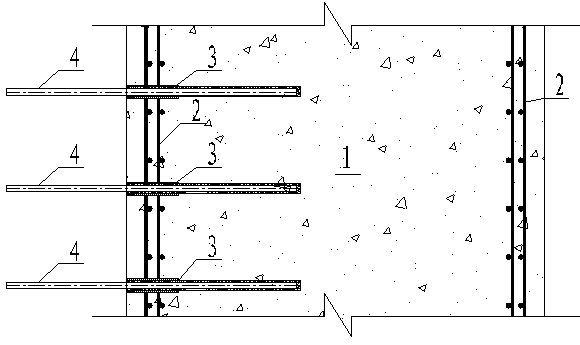

[0023] Step 1) Before the construction of the concrete structure 1, after the steel bar binding and adjustment are completed, install the post-planting anchor bar guide pipe 3, and then install the concrete pouring formwork. The large-volume concrete structure can also be reinforced first. After the calibration is completed, pre-embed the guide tube 3 for the post-planted anchor bar; The hole diameter is the same or larger than the reinforcement hole 2mm to 3mm of the post-planted anchor bars 4. The outer port is pressed against the concrete pouring formwork to ensure that the outer port of the post-planting anchor bar guide pipe 3 is flush with the concrete structure 1 poured in the subsequent steps, and the inner port of the post-plant anchor bar guide tube 3 passes through the area affected by the steel bars in the concrete structure, and then do After planting, the plugging of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com