Preparation method of porous nano polymer composite material

A composite material and nanoporous technology, applied in alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., to achieve low cost, simple preparation method, and improved strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0016] The present invention is a kind of preparation method of nanoporous polymer composite material, and its steps are:

[0017] (1) Add 0.1-0.5mol / L acid solution to the attapulgite pure soil and stir and disperse for 0.5h;

[0018] (2) Add aniline and γ-methacryloxypropyltrimethoxysilane, and stir for 0.5h;

[0019] (3) Add ammonium persulfate as an initiator, stir and let stand for 0.5h;

[0020] (4) Add acetanilide and stir to disperse for 0.5h;

[0021] (5) Suction filter to neutral, dry at 60°C, and grind;

[0022] (6) Wash with ethanol solution, filter with suction, dry at 60°C, and grind to obtain a dark green composite material.

[0023] The invention utilizes the principle that acetanilide has low solubility in water, 0.46g / 100g at 20°C, and high solubility in ethanol, 36.9g / 100g at 20°C, to form pores. Adding attapulgite clay as a support during the polyaniline polymerization process improves the strength of the composite material, and adding γ-methacryloxypro...

Embodiment 1

[0028] Example 1: Weigh 2.0 g of attapulgite clay, add 80 mL of 0.5 mol / L nitric acid and stir for 0.5 h, add 2.0 mL of aniline and 4.0 mL of γ-methacryloxypropyltrimethoxysilane and stir for 0.5 h, add 1.0g of ammonium persulfate, stirred and allowed to stand for 0.5h. Add 4.0 g of ground acetanilide, stir for 0.5 h, filter until neutral, dry at 60°C, grind, wash with ethanol solution, filter with suction, dry at 60°C, and grind to obtain a dark green composite material. The adsorption capacity for carbon tetrachloride is 14.28g / g. Such as figure 1 Shown is the scanning electron microscope picture of implementation case 1.

Embodiment 2

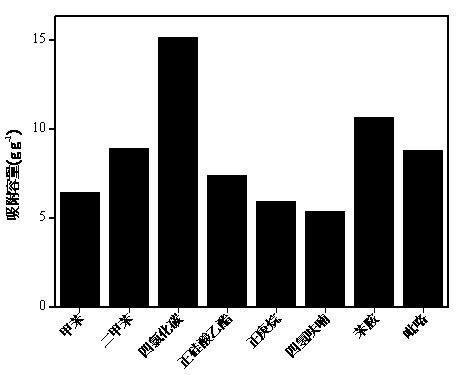

[0029] Example 2: Weigh 1.0 g of attapulgite clay, add 80 mL of 0.5 mol / L nitric acid and stir for 0.5 h, add 2.0 mL of aniline and 4.0 mL of γ-methacryloxypropyltrimethoxysilane and stir for 0.5 h, add 1.0 g ammonium persulfate, stirred and allowed to stand for 0.5h. Add 4.0 g of ground acetanilide, stir for 0.5 h, filter until neutral, dry at 60°C, grind, wash with ethanol solution, filter with suction, dry at 60°C, and grind to obtain a dark green composite material. The adsorption capacity for carbon tetrachloride is 15.16g / g. figure 2 Shown is the organic matter adsorption capacity of the composite material in Example 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com