Porous silicon carbide ceramic and preparation method thereof

A technology of porous silicon carbide and silicon carbide micropowder, which is applied in the field of silicon carbide ceramics, can solve the problems of poor environmental protection and achieve the effects of good environmental protection, pollution reduction and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

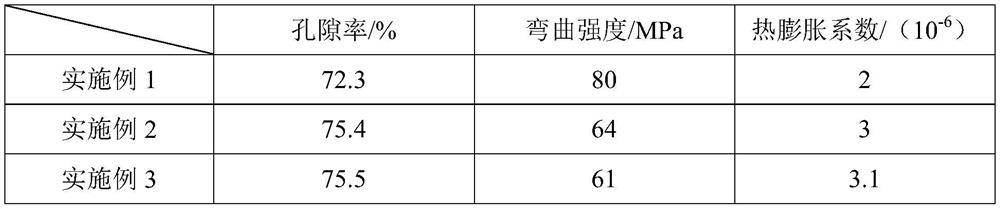

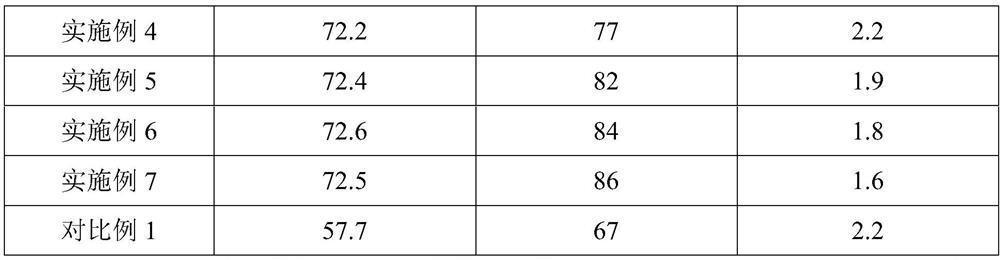

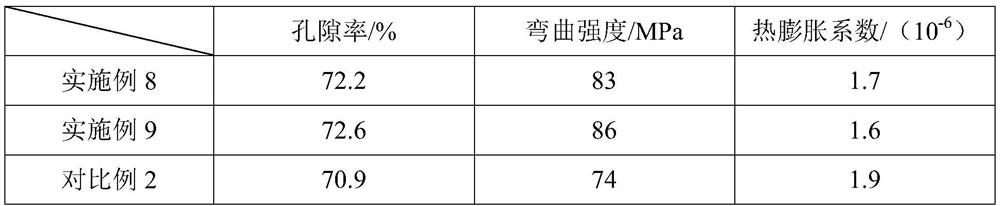

Examples

Embodiment 1

[0051] This application discloses a porous silicon carbide ceramic, including 100 parts of silicon carbide micropowder, 5 parts of sintering aid, 3 parts of pore-forming agent, 0.05 part of infiltration agent, 3 parts of crosslinking agent, 5 parts of dispersing agent, deionized water 50 parts, wherein the silicon carbide powder has a particle size of 80 μm, the pore-forming agent is straw powder with a particle size of 20 μm, the infiltration agent is barium carbonate powder, the sintering aid is potassium oxide powder, and the cross-linking agent is N, N -Methylenebisacrylamide, the dispersant is polyethyleneimine, and the component manufacturers are shown in Table 1.

[0052] component name Manufacturer Silicon carbide powder Shandong Jinde New Material Co., Ltd. straw powder Shaanxi Jinhe Agricultural Technology Co., Ltd. barium carbonate powder Foshan Junpeng Chemical Raw Materials Co., Ltd. Potassium oxide powder Shanghai Hongrui Che...

Embodiment 2

[0061] The difference from Example 1 is that the weight parts of straw fine powder added in Example 2 is 5 parts.

Embodiment 3

[0063] The difference from Example 2 is that the sintering aid added in Example 3 is 3 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com