Extruded foaming thermoplastic polyurethane elastomer particles and preparation method thereof

A thermoplastic polyurethane, extrusion foaming technology, applied in the field of foaming materials, can solve the problems of high cost and complicated foaming process, and achieve the effect of simple operation and uniform density distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

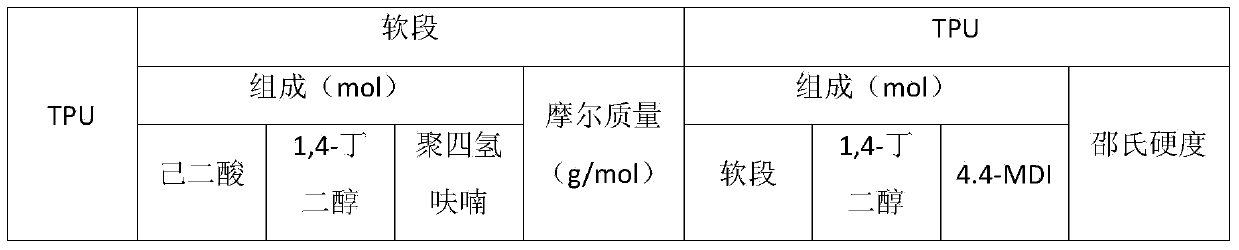

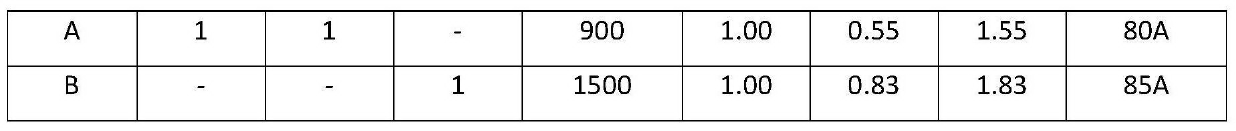

[0038] Mix 100 parts of thermoplastic polyurethane (TPU) particles A shown in Table 1, 0.2 parts by weight of talc, and 0.05 parts by weight of antioxidant 1010, and then put the above mixture into an extruder to granulate to obtain particles suitable for foaming Raw materials, and finally put the above-mentioned raw materials into a single-stage single-screw extruder. The extrusion speed of the material is controlled at 55 kg per hour, the speed of injecting n-butane into the extruder is controlled at 5 kg per hour, the die head pressure is 13Mpa, the die head temperature is 172°C, and the water temperature of the underwater pelletizer Controlled at 70°C. Materials can be added continuously according to the above component ratios for continuous production, and the foaming density of the obtained particles is 0.215g / cm 3 .

Embodiment 2

[0040] Mix 100 parts of thermoplastic polyurethane (TPU) particles A shown in Table 1, 0.3 parts by weight of silicon dioxide, and 0.07 parts by weight of antioxidant 245, and then put the above mixture into an extruder for granulation to obtain a compound suitable for foaming. The granular raw materials, and finally put the above raw materials into a single-stage single-screw extruder. The extrusion speed of the material is controlled at 55 kg per hour, the speed of injecting propane into the extruder is controlled at 7 kg per hour, the die head pressure is 15Mpa, the die head temperature is 168°C, and the water temperature of the underwater pelletizer is controlled at 55°C. The material can be added continuously according to the above-mentioned component ratio for continuous production, and the foaming density of the obtained particles is 0.202g / cm 3 .

Embodiment 3

[0042] Mix 100 parts of thermoplastic polyurethane (TPU) particles B shown in Table 1, 0.1 parts by weight of calcium carbonate, and 0.1 parts by weight of antioxidant 1010, and then put the mixture into an extruder to granulate to obtain a foamable Granular raw materials, and finally put the above raw materials into the co-rotating twin-screw extruder. The extrusion speed of the material is controlled at 40 kg per hour, the speed of injecting n-pentane into the extruder is controlled at 7 kg per hour, the die head pressure is 16Mpa, the die head temperature is 183°C, and the water temperature of the underwater pelletizer Controlled at 70°C. Materials can be added continuously according to the above component ratios for continuous production, and the foaming density of the obtained particles is 0.152g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

| foaming density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com