High pressure-resistant thermal insulation material and preparation method thereof

A thermal insulation material and high-temperature treatment technology, applied in the field of thermal insulation materials, can solve the problems of high thermal conductivity, inability to meet the high compressive strength, high temperature resistance, heat insulation and poor compressive performance of aerospace vehicles at the same time, and achieve low thermal conductivity coefficient, good application prospects, and the effect of little environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

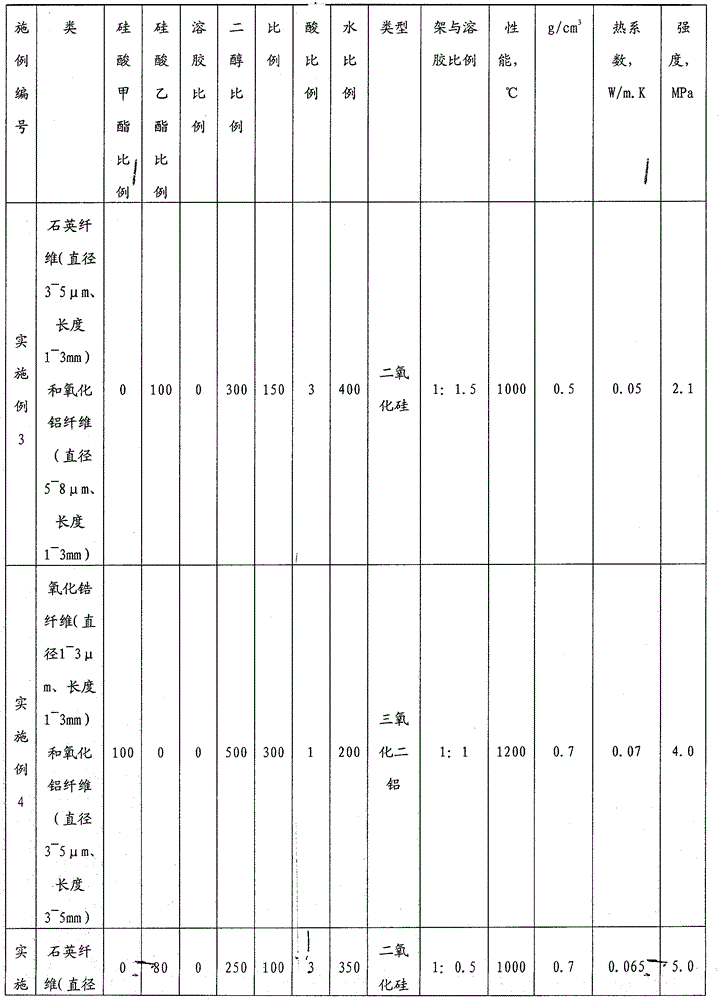

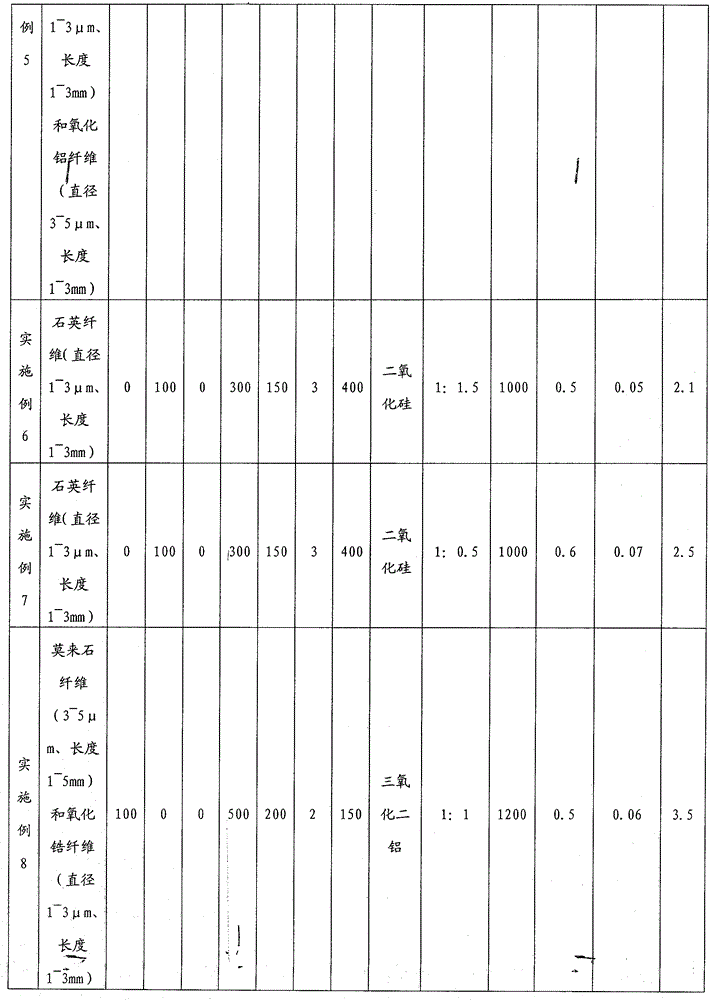

Embodiment 1

[0022] An embodiment of the present invention provides a high-compression heat-insulation material, which is an airgel composite material composed of a fiber ceramic skeleton and a sol, and undergoes drying and post-treatment processes; for the sol, its In the present invention, it mainly plays the role of improving the compression resistance and heat insulation performance of the material. The use temperature of the airgel prepared from the sol used in the present invention must be close to or reach the target use environment temperature, for example, from room temperature to 1200° C. or even higher. The sol can be a commercially available product, such as zirconia sol and / or alumina sol. The fiber ceramic skeleton is composed of a fiber matrix and a reinforcing agent, and undergoes drying and high-temperature treatment. The reinforcing agent is used to improve the compression resistance of the material and increase the compression resistance of the fiber matrix. The fiber m...

Embodiment 2

[0029] An embodiment of the present invention provides a method for preparing the above-mentioned high-pressure heat-insulating material, including:

[0030] Step 1. Dispersing and molding the fibers into a block fiber matrix;

[0031] Step 2, compounding the fiber matrix with a reinforcing agent, drying and high-temperature treatment to obtain a fiber ceramic skeleton, and the reinforcing agent is used to increase the compression resistance of the fiber matrix;

[0032] Step 3: Composite the fiber ceramic skeleton with the sol, and obtain the high compressive heat insulation material through drying and post-processing.

[0033] In the method, the diameter of the fiber is between 1 μm and 15 μm, and the length is between 1 μm and 10 mm.

[0034] In this method, the reinforcing agent is one or more of methyl orthosilicate, ethyl orthosilicate, silica sol, ethylene glycol, water, hydrochloric acid, and ammonia according to the mass ratio A: B: C : D: E: F: G mixed combination,...

Embodiment 3

[0047] Prepare the high-compression heat insulation material of the present invention, wherein the fiber matrix skeleton is composed of quartz fibers (3-5 μm in diameter, 1-3 mm in length) and alumina fibers (5-8 μm in diameter, 1-3 mm in length).

[0048] Firstly, the above two kinds of fibers are mixed and dispersed, shaped and dried to form a fiber matrix. Then one or more of methyl orthosilicate, ethyl orthosilicate, silica sol, ethylene glycol, water, hydrochloric acid, ammonia water according to the mass ratio 0:100:0:300:150:3:400 It is mixed to make a reinforcing agent, and then the reinforcing agent is impregnated into the fiber matrix. After drying and high temperature treatment, a reinforced fiber ceramic skeleton can be obtained. The fiber ceramic skeleton and silica sol are compounded according to the mass ratio of 1:1.5, and the high compressive heat insulation material is obtained through steps such as drying and post-treatment.

[0049] Test sample performanc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Thermal conductivity at room temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com