Sintered metal matrix friction sheet and deep processing production technology thereof

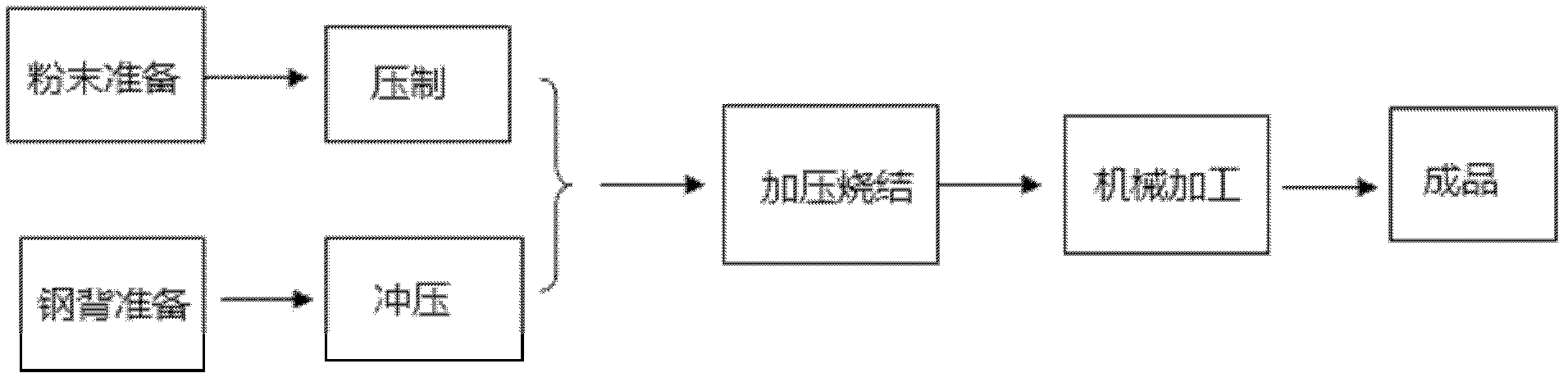

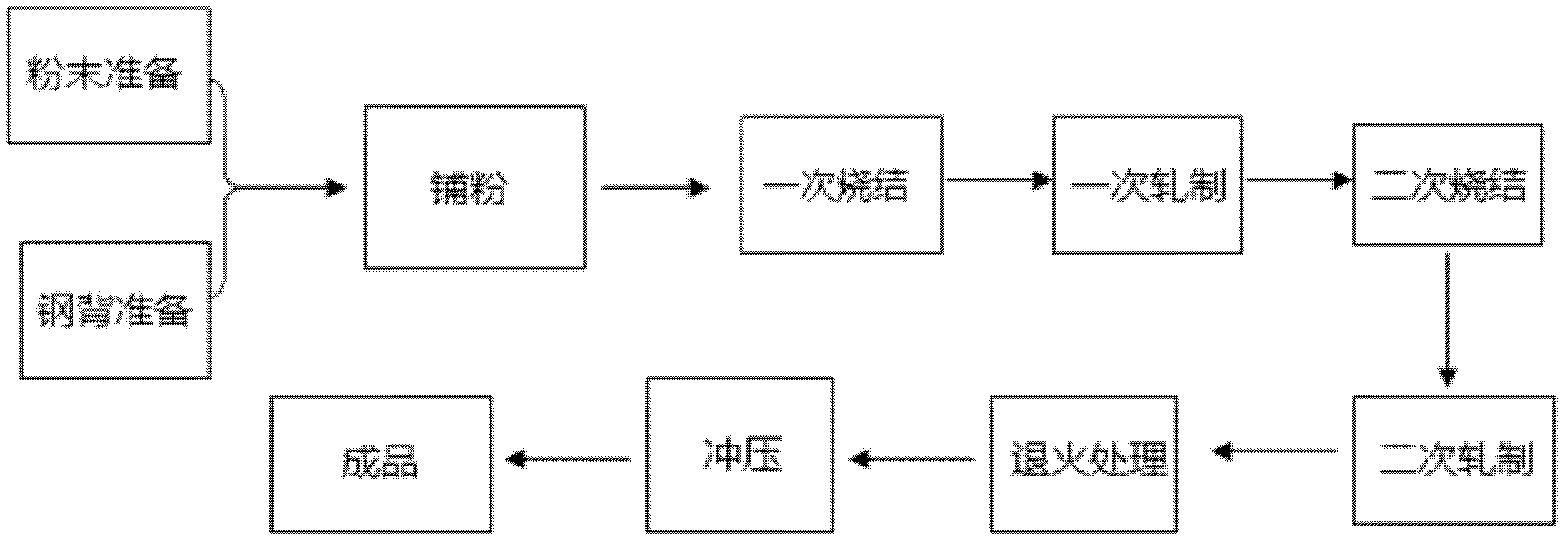

A sintered metal and production process technology, applied in the direction of friction linings, mechanical equipment, etc., can solve the problems of unstable product quality, large investment in production process, low production efficiency, etc., to solve the problem of large tonnage pressing equipment, small number of equipment, The effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Embodiment 1 Sintered copper-based friction plate and its preparation method

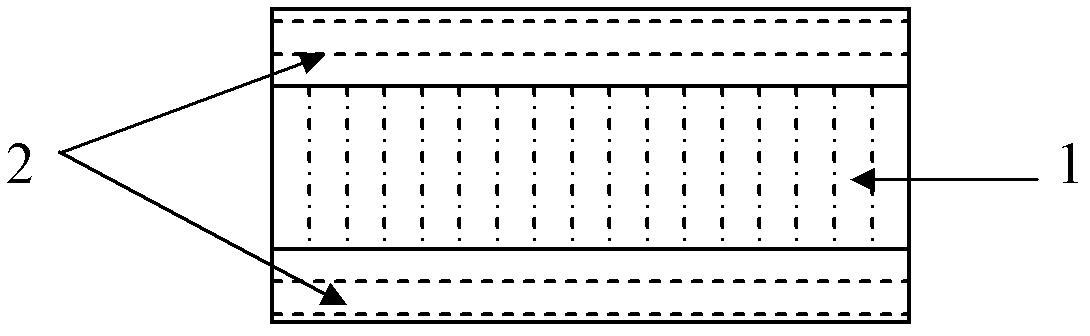

[0041] like figure 2 , 3 As shown, the thickness of the production steel back is 1.2mm, the total thickness of the copper-based friction plate is 2.0mm, and has two upper and lower friction layers; the composition formula of the copper-based friction material powder mixture is: copper 67.0%, lead 5.0%, tin 4.0%, silicon dioxide 8.0%, graphite 6.0% and iron 10.0%; percentages are mass percentages.

[0042] 1. Powder preparation: Dosing and weighing according to the composition formula of the copper-based friction material powder mixture, and put it into a "V" type mixer for mixing. The mixing time is 2 hours.

[0043] 2. Preparation of the steel back: Cut the 45Mn steel plate into strips with a width of 98 mm, plate copper on both sides, and the thickness of the copper layer is 12 μm.

[0044] 3. Powder spreading: spread the prepared copper-based friction material powder mixture on the ste...

Embodiment 2

[0052] Example 2 Sintered copper-based friction plate and its preparation method

[0053] like figure 2 As shown, the thickness of the production steel back is 1.2mm, the total thickness of the copper-based friction plate is 1.6mm, and has one friction layer; the composition formula of the copper-based friction material powder mixture is: copper 67.0%, lead 5.0%, tin 4.0% , silicon dioxide 8.0%, graphite 6.0% and iron 10.0%; percentages are mass percentages.

[0054] 1. Powder preparation: Dosing and weighing according to the composition formula of the copper-based friction material powder mixture, and put it into a "V" type mixer for mixing, and the mixing time is 4 hours.

[0055] 2. Steel back preparation: Cut the 45Mn steel plate into strips with a width of 98mm, plate copper on one side, and the thickness of the copper plated layer is 12μm.

[0056] 3. Powder spreading: spread the prepared copper-based friction material powder mixture on the steel back with a powder sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com