Preparation method for mullite fiber porous thermal insulation material

A technology of mullite fiber and thermal insulation materials, applied in ceramic products, applications, household appliances, etc., to achieve the effects of simple process flow, low energy consumption, and controllable material density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

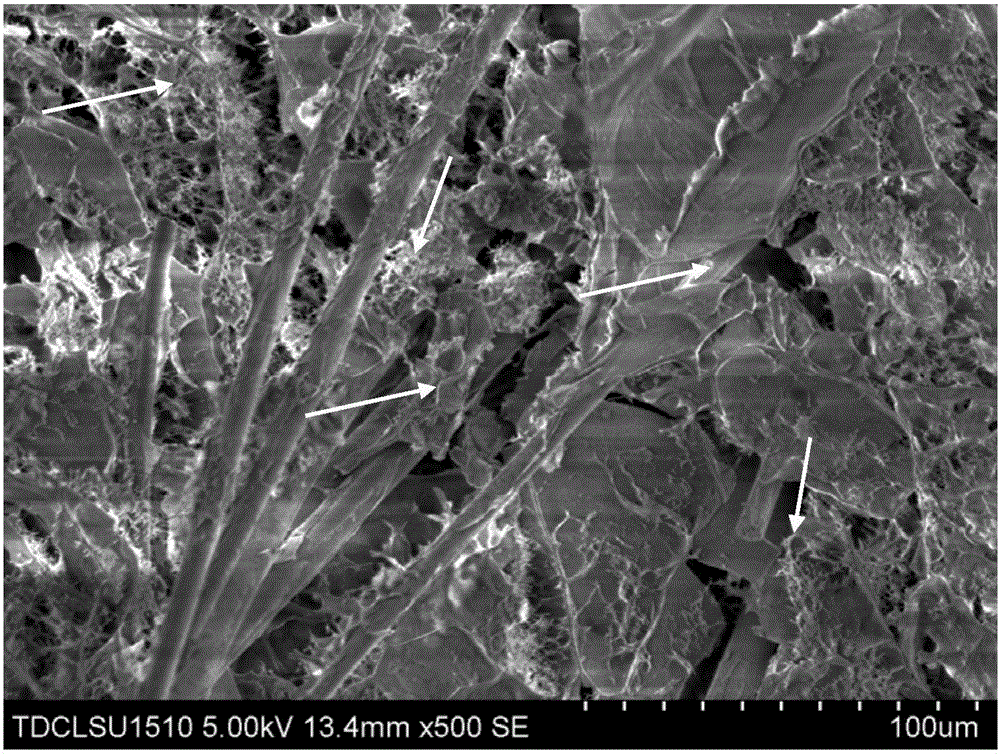

Embodiment 1

[0023] (1) Weigh mullite fiber and silica sol by the mass ratio of mullite fiber / silica sol=3.3, weigh agar powder by the mass ratio of agar powder / (silica sol+mullite fiber)=1:9 , mix agar powder and silica sol, set the density of the prepared mullite fiber porous material to be 0.2g / cm 3 , to which distilled water was added to a volume of 5M cm 3 (M is the total mass of the weighed mullite fiber, silica sol, and agar powder), heated in a water bath at 78°C and stirred evenly to obtain a mixed solution of silica sol and agar powder;

[0024] (2) Slowly add mullite fiber to the mixed solution of silica sol and agar powder obtained in step (1) under the condition of heating in a water bath at 78°C, and magnetically stir while adding mullite fiber, so that the mullite fiber Can be evenly dispersed in the mixed solution of silica sol and agar powder;

[0025] (3) Pour the mixed solution of evenly mixed mullite fiber, silica sol, and agar powder into a plastic beaker, and put th...

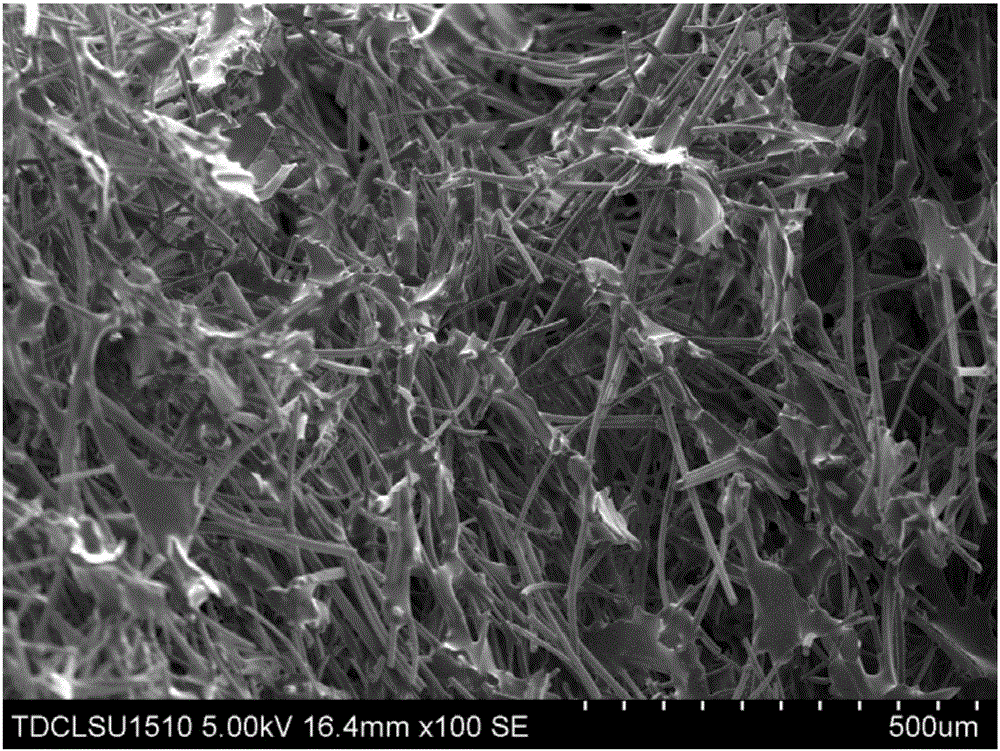

Embodiment 2

[0030] (1) Weigh mullite fiber and silica sol by the mass ratio of mullite fiber / silica sol=1.67, weigh agar powder by the mass ratio of agar powder / (silica sol+mullite fiber)=1:9 , mix agar powder and silica sol, set the density of the prepared mullite fiber porous material to be 0.2g / cm 3 , to which distilled water was added to a volume of 5M cm 3 (M is the total mass of the weighed mullite fiber, silica sol, and agar powder), heated in a water bath at 78°C and stirred evenly to obtain a mixed solution of silica sol and agar powder;

[0031] (2) Slowly add the mullite fiber to the mixed solution of silica sol and agar powder obtained in step (1) under the condition of heating in a water bath at 78°C, and stir magnetically while adding the fiber, so that the mullite fiber can be evenly dispersed In the mixed solution of silica sol and agar powder;

[0032] (3) Pour the mixed solution of evenly mixed mullite fiber, silica sol, and agar powder into a plastic beaker, and put t...

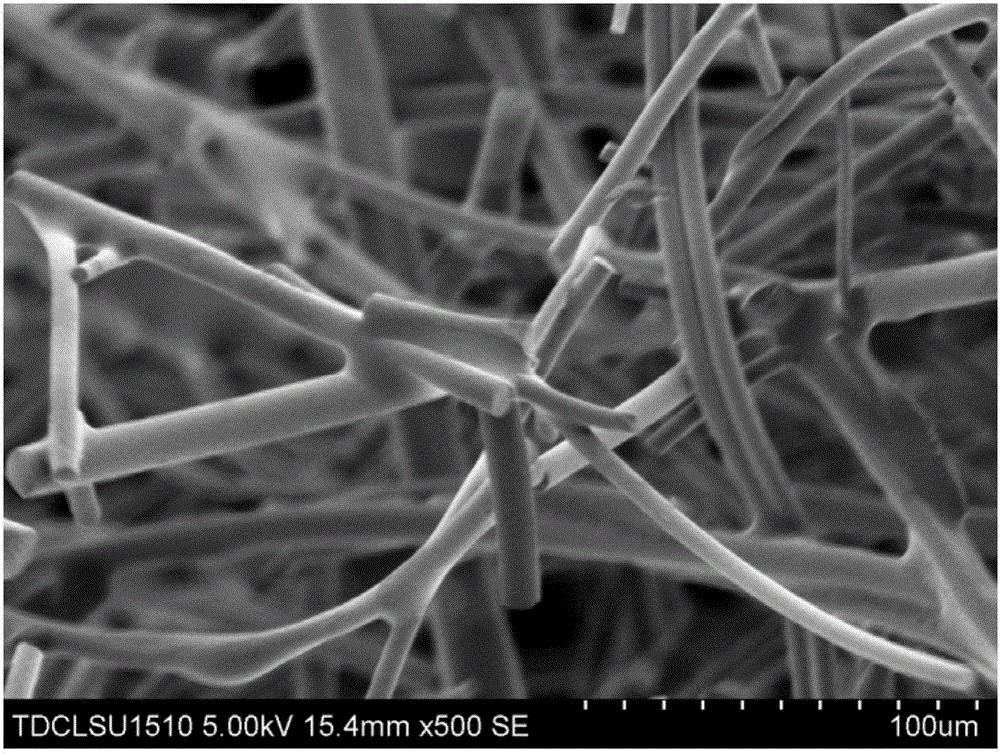

Embodiment 3

[0036] (1) weigh mullite fiber and silica sol (by the mass ratio of mullite fiber / silica sol=6.67, weigh agar by the mass ratio of agar powder / (silica sol+mullite fiber)=1:9 powder, agar powder and silica sol are mixed, and the density of the prepared mullite fiber porous material is set to be 0.2g / cm 3 , to which distilled water was added to a volume of 5M cm3 (M is the total mass of the weighed mullite fiber, silica sol, and agar powder), heated in a water bath at 78°C and stirred evenly to obtain a mixed solution of silica sol and agar powder;

[0037] (2) Slowly add the mullite fiber to the mixed solution of silica sol and agar powder obtained in step (1) under the condition of heating in a water bath at 78°C, and stir magnetically while adding the fiber, so that the mullite fiber can be evenly dispersed In the mixed solution of silica sol and agar powder;

[0038] (3) Pour the mixed solution of evenly mixed mullite fiber, silica sol, and agar powder into a plastic beaker...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com