Forming method for ceramic hollow balls

A technology of ceramic hollow sphere and forming method, applied in the field of ceramic forming and ceramic hollow sphere forming, can solve the problems of high cost, low green body density, loose sintering, etc. Easy to operate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

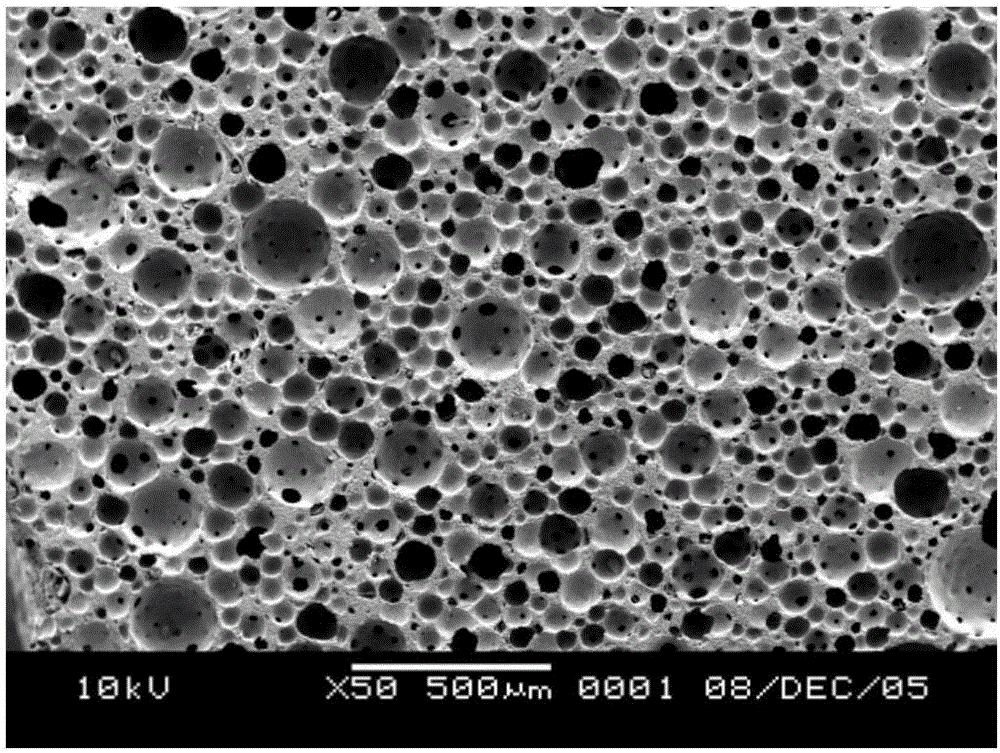

Image

Examples

Embodiment 1

[0021] In terms of parts by mass, mix 160g of silicon carbide ceramic micropowder less than 20 microns, 30g of closed-cell pore-forming agent, 20g of calcium chloride, 10g of glass powder, 5g of dispersant and 100g of water, and heat in a water bath To 45°C, stir in a spherical reactor to form a uniform slurry, under stirring, then use a precision peristaltic pump to drop a 6% sodium alginate aqueous solution at a rate of 1.5mL / s, form a ball, filter, and dry , and then sintered in a high-temperature sintering furnace at 900°C for 2 hours to make a density of 1.03g / cm 3 , Silicon carbide ceramic hollow balls with a diameter of 1-3.5mm. Wherein, the closed-cell pore-forming agent is calcium carbonate, and the dispersant is acrylic acid.

Embodiment 2

[0023] In terms of parts by mass, after mixing 160g of silicon carbide ceramic micropowder less than 20 microns, 25g of closed-cell pore-forming agent, 20g of calcium chloride, 10g of glass powder, 5g of dispersant and 100g of water, heat in a water bath To 45°C, stir in a spherical reactor to form a uniform slurry, under stirring, then use a precision peristaltic pump to drop a 6% sodium alginate aqueous solution at a rate of 1.5mL / s, form a ball, filter, and dry , and then sintered in a high-temperature sintering furnace at 900°C for 1.5h to make a density of 1.15g / cm 3 , Silicon carbide ceramic hollow balls with a diameter of 1-3mm. Wherein, the closed-cell pore-forming agent is aluminum powder, and the dispersant is ammonium polyacrylate.

Embodiment 3

[0025] In parts by mass, 400g of silicon carbide ceramic micropowder less than 20 microns, 18g of boron carbide (0.5 micron) micropowder, 55g of closed-cell pore-forming agent, 20g of clay, 60g of calcium chloride, and 12g of dispersant After mixing with 320g of water, heat it in a water bath to 45°C and stir it into a uniform slurry in a spherical reactor. Under stirring, use a precision peristaltic pump to drop a 4% sodium alginate aqueous solution at a rate of 2mL / s , after being formed into balls, filtered, dried, and then sintered in a high-temperature sintering furnace at 1450°C for 0.5h to make a density of 1.85g / cm 3 SiC composite ceramic hollow spheres. Wherein, the pore-closing agent is a mixture of calcium sulfate and aluminum sulfate, and the dispersant is tetramethylammonium hydroxide.

[0026] The diameter of the composite ceramic ball prepared in this example is 1-3.5 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com