Aircooled crushing device and method of molten steel slag

A processing device and processing method technology, applied in the direction of recycling technology, process efficiency improvement, etc., can solve the problems of large amount of steam, unorganized discharge, increase in viscosity of steel slag, etc., and achieve a high degree of automation, high efficiency, and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

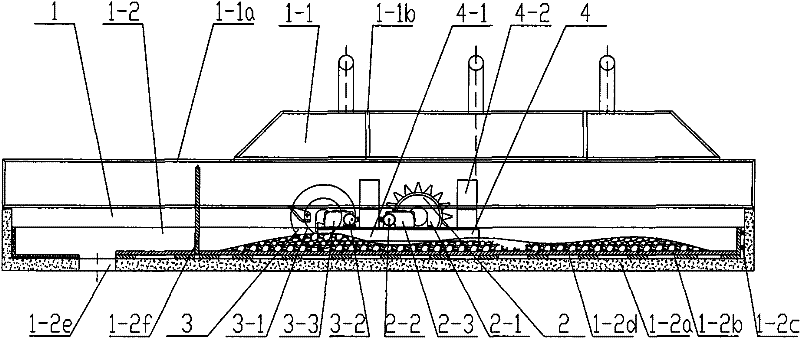

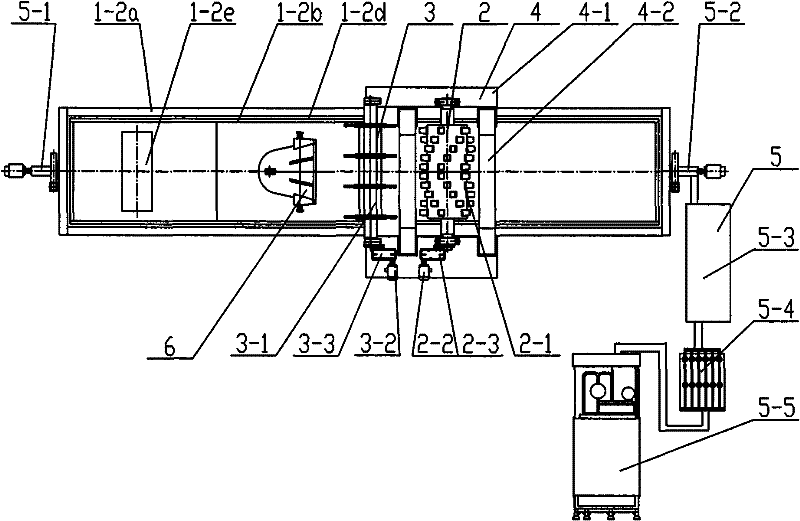

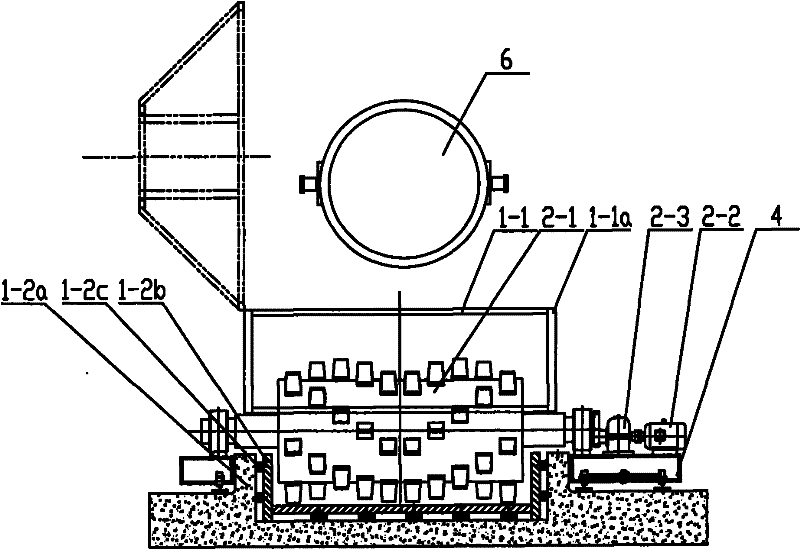

[0043] Such as figure 1 , 2 , 3 is a schematic structural view of a molten steel slag air-cooled roll crushing treatment device of the present invention, including a roll crushing chamber 1, a roll crushing device 2, a slag pushing device 3, a walking trolley 4 and a waste heat recovery and utilization device 5; The crushing device 2 and the slag pushing device 3 are located on the traveling trolley 4, and the traveling trolley 4 moves in the roller crushing chamber 1 along the rails on both sides of the roller crushing chamber 1.

[0044] The roll crushing chamber 1 includes a heat collecting cover 1-1 and a crushing pool 1-2, the heat collecting cover 1-1 is located above the crushing pool 1-2, and constitutes a closed space with the crushing pool 1-2; The cover 1-1 is used to collect hot air; the crushing tank 1-2 is used to provide a space for holding molten steel slag.

[0045] The heat collecting cover 1-1 includes a housing body 1-1a, a housing door 1-1b, a high tempe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com