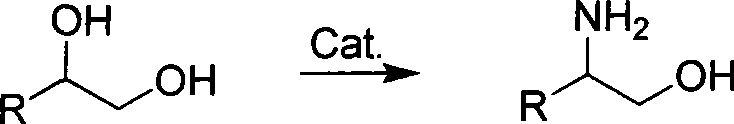

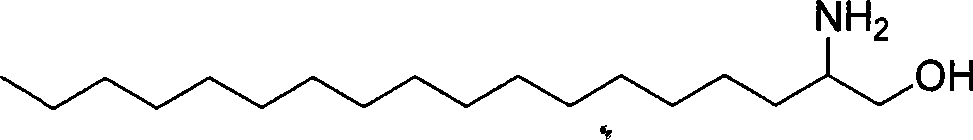

Method for preparing 2-amido-1-alkyl alcohol and catalyst preparation method

A technology of alkyl alcohol and catalyst, which is applied in the field of catalyst preparation, can solve problems such as poor catalytic effect, and achieve the effects of low cost, high economic benefit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: the production method of 2-amino-1-propanol:

[0027] 15 grams of an oxidative solid-supported catalytic amination catalyst was packed in a single-tube fixed-bed reactor with a diameter of 15 mm and a length of 1.0 m, and the filling height of the catalyst layer was 0.3 m. The catalyst in the reactor is kept in a hydrogen-facing state with a hydrogen flow passing through it, and the temperature is maintained at 400° C. for 5 hours for reduction to make the catalyst active. After the reduction, the temperature is lowered to 130°C, the hydrogen pressure is raised to 5.0MPa, and the 1,4-dioxane solution of 1,2-propylene glycol with a volume percentage of 30% and liquid ammonia enter the catalytic amine from the upper end through the preheater In the reactor, the flow rate of 1,2-propylene glycol solution is 60 milliliters per hour, and the feed rate of liquid ammonia is 20 milliliters per hour. The catalytic amination reaction product flows out from the lo...

Embodiment 2

[0031] Embodiment 2: the production method of 2-amino-1-butanol:

[0032] 15 grams of an oxidative solid-supported catalytic amination catalyst was packed in a single-tube fixed-bed reactor with a diameter of 15 mm and a length of 1.0 m, and the filling height of the catalyst layer was 0.3 m. The catalyst in the reactor is kept in a hydrogen-facing state with a hydrogen flow passing through it, and the temperature is maintained at 400° C. for 5 hours for reduction to make the catalyst active. Cool down to 160 DEG C after reduction finishes, hydrogen pressure rises to 5.0MPa, 1,4-dioxane and toluene mixed solution (1,4-dioxane Six rings: toluene volume ratio 1:2) and liquid ammonia enter the catalytic amination reactor from the upper end through the preheater, the flow rate of 1,2-butanediol solution is 60 ml per hour, and the feed rate of liquid ammonia is 20 ml per hour . The catalytic amination reaction product flows out from the lower end of the fixed-bed reactor, and t...

Embodiment 3

[0036] Embodiment 3: the production method of 2-amino-1-butanol:

[0037] 15 grams of an oxidative solid-supported catalytic amination catalyst was packed in a single-tube fixed-bed reactor with a diameter of 15 mm and a length of 1.0 m, and the filling height of the catalyst layer was 0.3 m. The catalyst in the reactor is kept in a hydrogen-facing state with a hydrogen flow passing through it, and the temperature is maintained at 400° C. for 5 hours for reduction to make the catalyst active. Cool down to 160 DEG C after reduction finishes, hydrogen pressure rises to 5.0MPa, 1,4-dioxane and toluene mixed solution (1,4-dioxane Six rings: toluene volume ratio 1:2) and liquid ammonia enter the catalytic amination reactor from the upper end through the preheater, the flow rate of 1,2-butanediol solution is 60 ml per hour, and the feed rate of liquid ammonia is 20 ml per hour . The catalytic amination reaction product flows out from the lower end of the fixed-bed reactor, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com