Fiber-rich wet extrusion plant meat and preparation method thereof

A plant and wet process technology, applied in the field of fiber-rich wet-extruded plant meat and its preparation, can solve the problems of unfavorable fiber formation, increased lipopolysaccharide permeability, increased hardness and chewiness, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] (1) Soy protein isolate and gluten powder are weighed and mixed according to the ratio of (50:50, w / w), and 5% citrus fiber is added, and stirred for 10 minutes to disperse the mixture evenly;

[0039] (2) Turn on the twin-screw extruder and preheat it for 15 minutes. The temperatures of the second to seventh sections of the heating section are 50, 70, 100, 120, 140, and 150°C respectively, the cooling temperature is 55°C, and the screw speed is 200rpm .

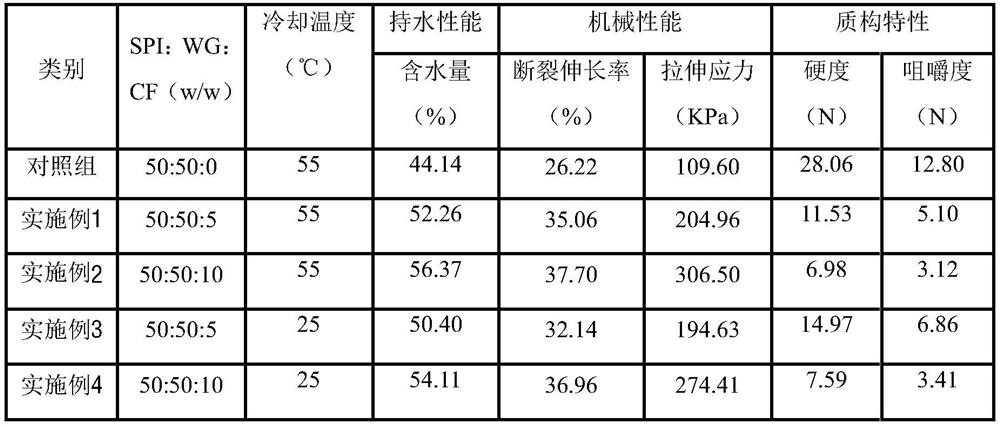

[0040] (3) Add the mixed vegetable protein into the twin-screw extruder at a constant feed rate, and at the same time add water at a constant rate with a constant flow pump, so that the sample is output from the cooling plate at a constant rate. The water-holding properties, tensile mechanical properties and texture properties of the prepared vegetable protein-based artificial meat are shown in Table 1.

Embodiment 2

[0042] (1) Weighing and mixing soybean protein isolate and gluten powder according to the ratio of (50:50, w / w), adding 10% citrus fiber, stirring for 10 minutes to disperse the mixture evenly;

[0043] (2) Turn on the twin-screw extruder and preheat it for 15 minutes. The temperatures of the second to seventh sections of the heating section are 50, 70, 100, 120, 140, and 150°C respectively, the cooling temperature is 55°C, and the screw speed is 200rpm .

[0044] (3) Add the mixed vegetable protein into the twin-screw extruder at a constant feed rate, and at the same time add water at a constant rate with a constant flow pump, so that the sample is output from the cooling plate at a constant rate. The water-holding properties, tensile mechanical properties and texture properties of the prepared vegetable protein-based artificial meat are shown in Table 1.

Embodiment 3

[0046] (1) Soy protein isolate and gluten powder are weighed and mixed according to the ratio of (50:50, w / w), and 5% citrus fiber is added, and stirred for 10 minutes to disperse the mixture evenly;

[0047] (2) Turn on the twin-screw extruder and preheat it for 15 minutes. The temperatures of the second to seventh sections of the heating section are 50, 70, 100, 120, 140, and 150°C respectively, the cooling temperature is 25°C, and the screw speed is 200rpm .

[0048] (3) Add the mixed vegetable protein into the twin-screw extruder at a constant feed rate, and at the same time add water at a constant rate with a constant flow pump, so that the sample is output from the cooling plate at a constant rate. The water-holding properties, tensile mechanical properties and texture properties of the prepared vegetable protein-based artificial meat are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com