Cyclic production method of glyphosate

A production method and technology of glyphosate, applied in chemical instruments and methods, botanical equipment and methods, biocides, etc., can solve the problems of unsatisfactory yield and cost, low recovery rate, low concentration ratio, etc., and achieve comprehensive Significant economic and social benefits, reducing waste liquid discharge, and reducing energy consumption for evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

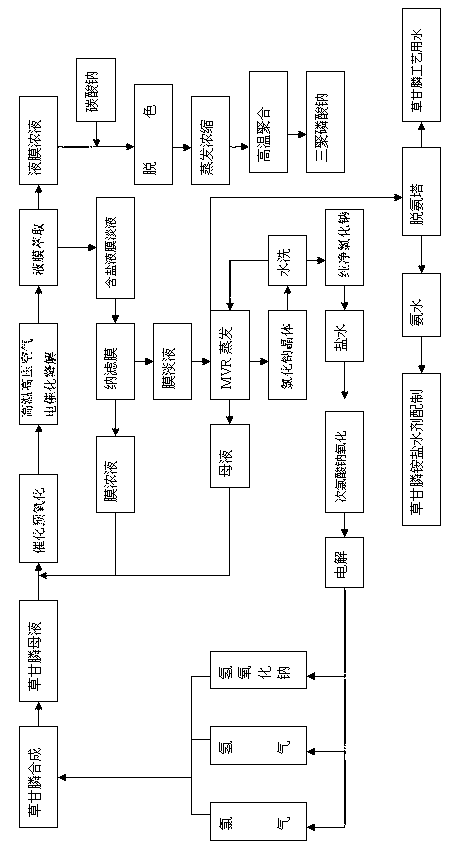

Image

Examples

Embodiment 1

[0028] As shown in the figure, a glyphosate recycling production method specifically includes the following process steps:

[0029] 1) Chlorine and yellow phosphorus to produce phosphorus trichloride;

[0030] 2) Phosphorus trichloride and methanol react to generate dimethyl phosphite;

[0031] 3) Using dimethyl phosphite as raw material to obtain glyphosate and glyphosate mother liquor through the alkyl ester method;

[0032] 4) The glyphosate mother liquor is neutralized with liquid alkali to make the PH value 9, the lower layer is the alkali mother liquor, the upper layer triethylamine is separated, and the alkali mother liquor is then rectified to recover triethylamine, and the recovered triethylamine is added with solid hydrogen After dehydration of sodium oxide, the production process of returning to the alkyl ester method is used as a catalyst, and 1000kg of secondary alkali mother liquor is obtained after separating triethylamine;

[0033] 5) Adjust the pH value of t...

Embodiment 2

[0040] As shown in the figure, a glyphosate recycling production method specifically includes the following process steps:

[0041] 1) Chlorine and yellow phosphorus to produce phosphorus trichloride;

[0042] 2) Phosphorus trichloride and methanol react to generate dimethyl phosphite;

[0043] 3) Using dimethyl phosphite as raw material to obtain glyphosate and glyphosate mother liquor through the alkyl ester method;

[0044] 4) The glyphosate mother liquor is neutralized with liquid alkali to make the pH value 10, the lower layer is the alkali mother liquor, the upper layer triethylamine is separated, and the alkali mother liquor is then rectified to recover triethylamine, and the recovered triethylamine is added with solid hydrogen After dehydration of sodium oxide, the production process of returning to the alkyl ester method is used as a catalyst, and 1000kg of secondary alkali mother liquor is obtained after separating triethylamine;

[0045] 5) Adjust the pH value of ...

Embodiment 3

[0053] As shown in the figure, a glyphosate recycling production method specifically includes the following process steps:

[0054] 1) Chlorine and yellow phosphorus to produce phosphorus trichloride;

[0055] 2) Phosphorus trichloride and methanol react to generate dimethyl phosphite;

[0056] 3) Using dimethyl phosphite as raw material to obtain glyphosate and glyphosate mother liquor through the alkyl ester method;

[0057] 4) The glyphosate mother liquor is neutralized with liquid alkali to make its PH value 11, the lower layer is the alkali mother liquor, the upper layer triethylamine is separated, and the alkali mother liquor is then rectified to recover triethylamine, and the recovered triethylamine is added with solid hydrogen After dehydration of sodium oxide, the production process of returning to the alkyl ester method is used as a catalyst, and 1000kg of secondary alkali mother liquor is obtained after separating triethylamine;

[0058] 5) Adjust the pH value of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com