Glyphosate preparation and method for preparing same

A glyphosate and preparation technology, applied in the field of glyphosate preparation and its preparation, can solve the problem that glyphosate cannot directly obtain glyphosate preparation, and achieve the goal of reducing equipment and personnel investment, reducing environmental pressure, and reducing waste water The effect produced

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

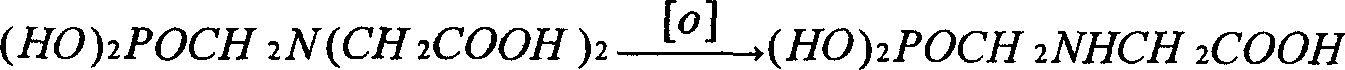

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: the preparation of glyphosate preparation

[0037] step:

[0038] (a) Get 224g (content 24%) of the IDA reaction solution that catalytic dehydrogenation makes in the four-neck flask with stirring, add phosphorous acid 45g; Heat up, dropwise add 30% formaldehyde solution 50g and reflux for three hours.

[0039] (b) Add 110 g of water, 0.5 g of sodium tungstate, and 65 g of hydrogen peroxide (content 28%) to the diglyphosate obtained in step (a). Stir and heat up. Control the temperature within the range of 50°C to 90°C and keep it warm for 60 minutes; after the heat preservation is over, cool the temperature to 25°C to 55°C and keep it warm for 40 minutes. After the heat preservation was completed, 11 g of 10% ferrous sulfate aqueous solution was added dropwise when it was cooled to below 30° C. After the dropwise addition, 100 g of dehydration under reduced pressure was carried out, and then 35 g of isopropylamine was added dropwise. After the dropwise ...

Embodiment 2

[0040] Embodiment 2: the preparation of glyphosate preparation:

[0041] step:

[0042] 60 g of water, 0.1 g of sodium tungstate, and 70 g of hydrogen peroxide (content 28%) were added to the reaction mixture obtained in step (a) of Example 1. Stir and heat up. Control the temperature within the range of 50°C to 90°C and keep it warm for 80 minutes; after the heat preservation is over, cool the temperature to 25°C to 55°C and keep it warm for 40 minutes. When cooling below 30°C after the heat preservation, 17g of 10% ferrous sulfate aqueous solution was added dropwise, and 55g of dehydration under reduced pressure was carried out after the dropwise addition, and then ammonia gas was passed into the reactor. Until the pH value of the mixed liquid in the reactor reaches the range of 5-7. Add 10 g of a mixture of alkyl glucoside and coconut oil betaine with a mass ratio of 1:1 and stir evenly. After sampling analysis, its active ingredient content is 30.8%.

Embodiment 3

[0043] Embodiment 3: the preparation of glyphosate preparation:

[0044] step:

[0045]110 g of water, 0.3 g of sodium tungstate, and 55 g of hydrogen peroxide (content 28%) were added to the reaction mixture obtained in step (a) of Example 1. Stir and heat up. Control the temperature within the range of 65°C to 90°C and keep it warm for 90 minutes; after the heat preservation is over, cool the temperature to 25°C to 55°C and keep it warm for 50 minutes. After the heat preservation was completed, 25 g of 10% ferrous sulfate aqueous solution was added dropwise when cooling below 30° C., and 95 g of dehydration under reduced pressure was carried out after the dropwise addition, and 40 g of isopropylamine was then added dropwise. After the dropwise addition, the pH value of the mixed solution in the reactor was about 5. Add tallow amine ethylate 20g and stir evenly. Through sampling analysis, its active ingredient content is 30.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com