Process of treating glyphosate producing effluent

A treatment method and technology for producing wastewater, which can be used in natural water treatment, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc. Economic and environmental benefits, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

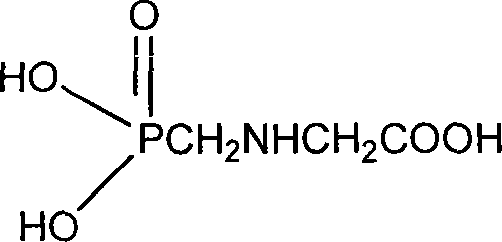

Image

Examples

Embodiment 1

[0014] Embodiment 1: get the glyphosate production waste water 100ml waste water (through detection glyphosate content 1.25%, COD value 41695mg / L) after adding alkali and recovering catalyst, add 22 grams of calcium oxide, stir reaction 24 hours, filter, The filter cake is dissolved with hydrochloric acid, and the glyphosate solution is recovered. The glyphosate content of the filtrate was detected to be 0.031%, and the COD value was 2138mg / L.

Embodiment 2

[0015] Embodiment 2: get the glyphosate production waste water 100ml waste water (through detection glyphosate content 1.32%, COD value 43672mg / L) after adding alkali neutralization and recovery catalyst, add 40 grams of magnesium oxide, stir reaction 12 hours, filter, The filter cake is dissolved with sulfuric acid, and the glyphosate solution is recovered. The glyphosate content of the filtrate was detected to be 0.032%, and the COD value was 2242mg / L.

Embodiment 3

[0016] Embodiment 3: get the glyphosate production waste water 100ml waste water (through detection glyphosate content 1.29%, COD value 42632mg / L) after adding alkali and recovering catalyst, add 40ml concentration and be 55% calcium chloride solution, stir React for 20 hours, filter, dissolve the filter cake with nitric acid, and recover the glyphosate solution. The glyphosate content of the filtrate was detected to be 0.029%, and the COD value was 2182mg / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com