Symmetrical character maxillofacial prosthesis producing method based on three-dimensional visual sensation measurement

A three-dimensional vision, pseudo-complex technology, applied in the fields of mechanical engineering and medical engineering, can solve the problems of long data acquisition time, laser light source damage, long production cycle, etc. The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the preparation of the accompanying drawings and the human eye prosthesis:

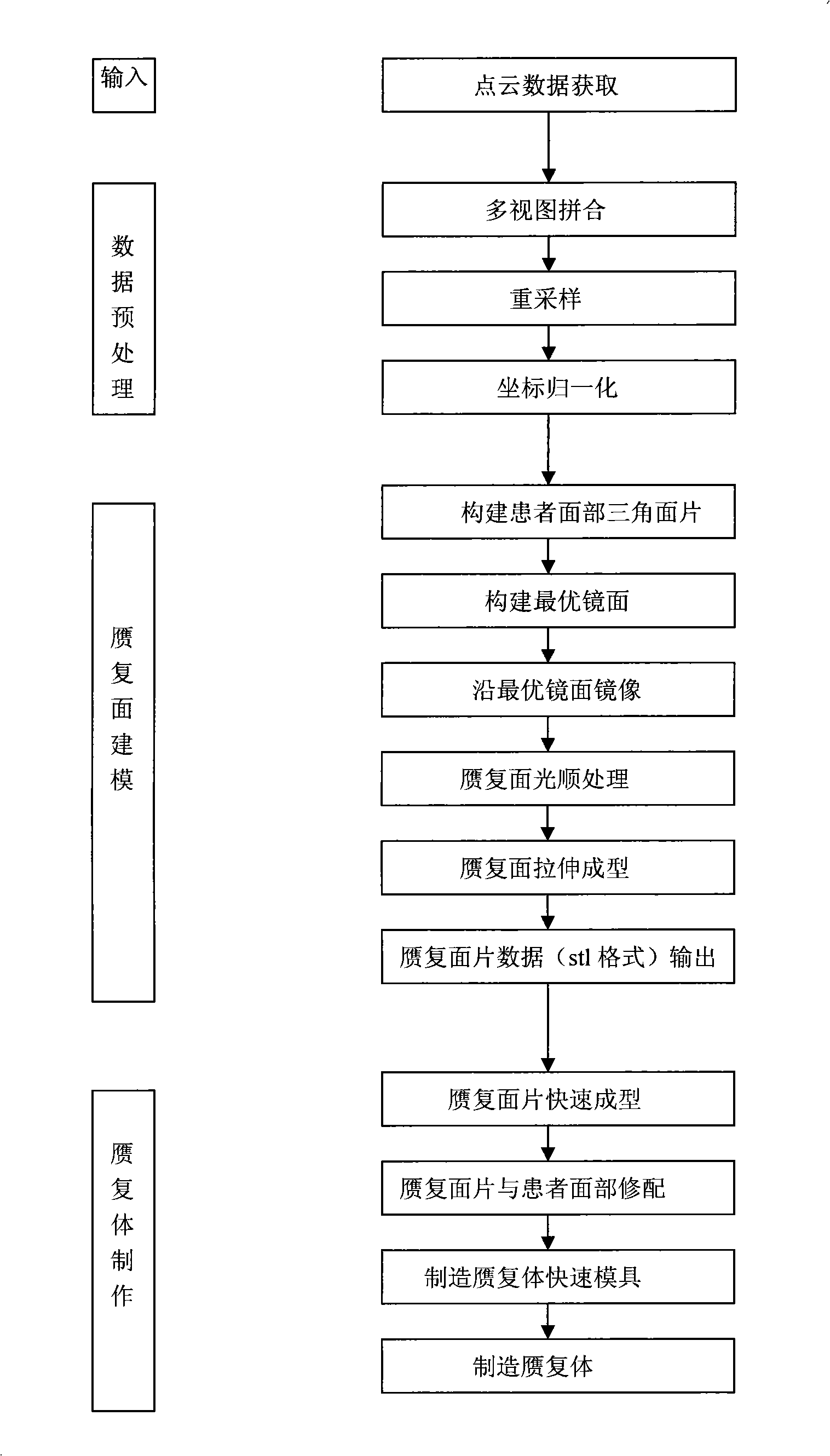

[0018] Such as figure 1 Shown, the present invention comprises the following steps:

[0019] 1) Obtain multi-view point cloud data of the patient's facial shape by using a dual-monocular three-dimensional measurement system;

[0020] 2) Preprocessing of point cloud data: including point cloud useless point removal, multi-view registration, resampling, and coordinate normalization. First remove the useless points of the point cloud, then merge the multi-view point cloud data, and finally merge into a point cloud, which is saved after uniform sampling;

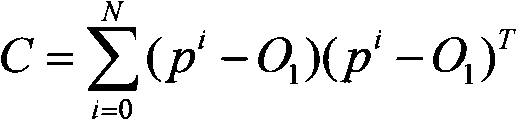

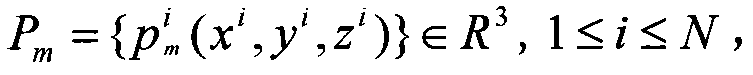

[0021] 3) Prosthetic surface modeling: construct the triangular surface sheet based on the point cloud data of the patient's facial measurement site; find the optimal mirror surface; mirror the corresponding intact eye to the defective eye a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com