Construction technology of extra-large steel structure canopy under severe conditions

A technology for construction technology and harsh conditions, applied in building structure, special data processing applications, instruments, etc., can solve problems such as increased on-site welding, heavy rainfall, strong sunlight, etc., to avoid component repair work, reduce engineering risks, and ensure safety High security effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

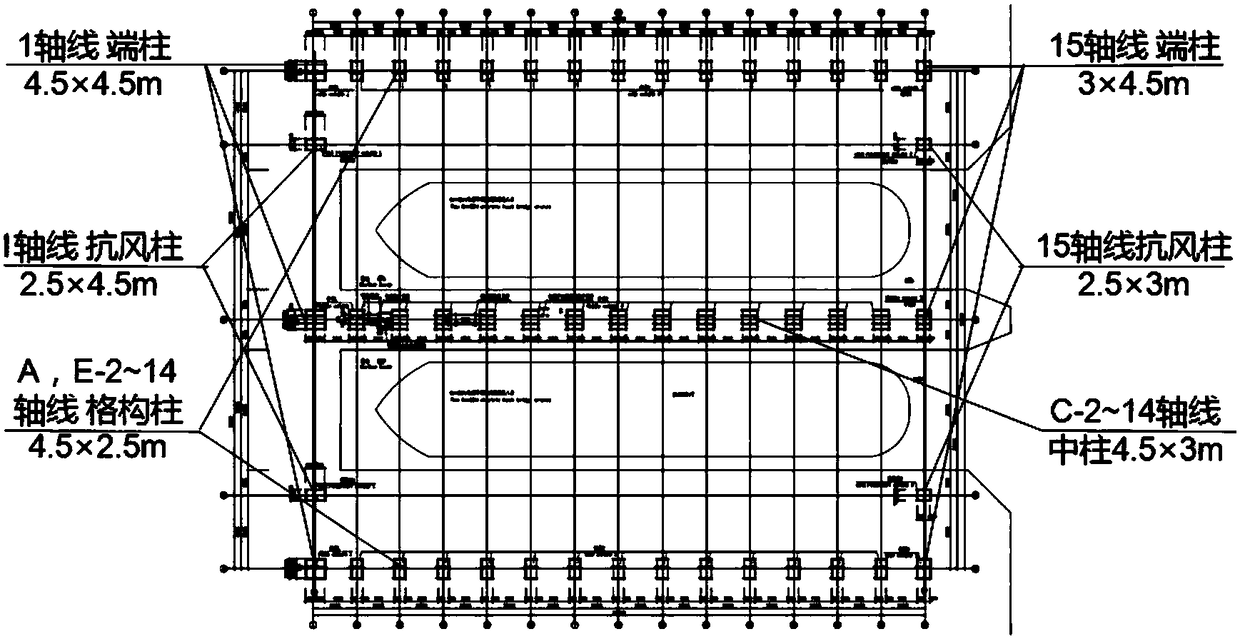

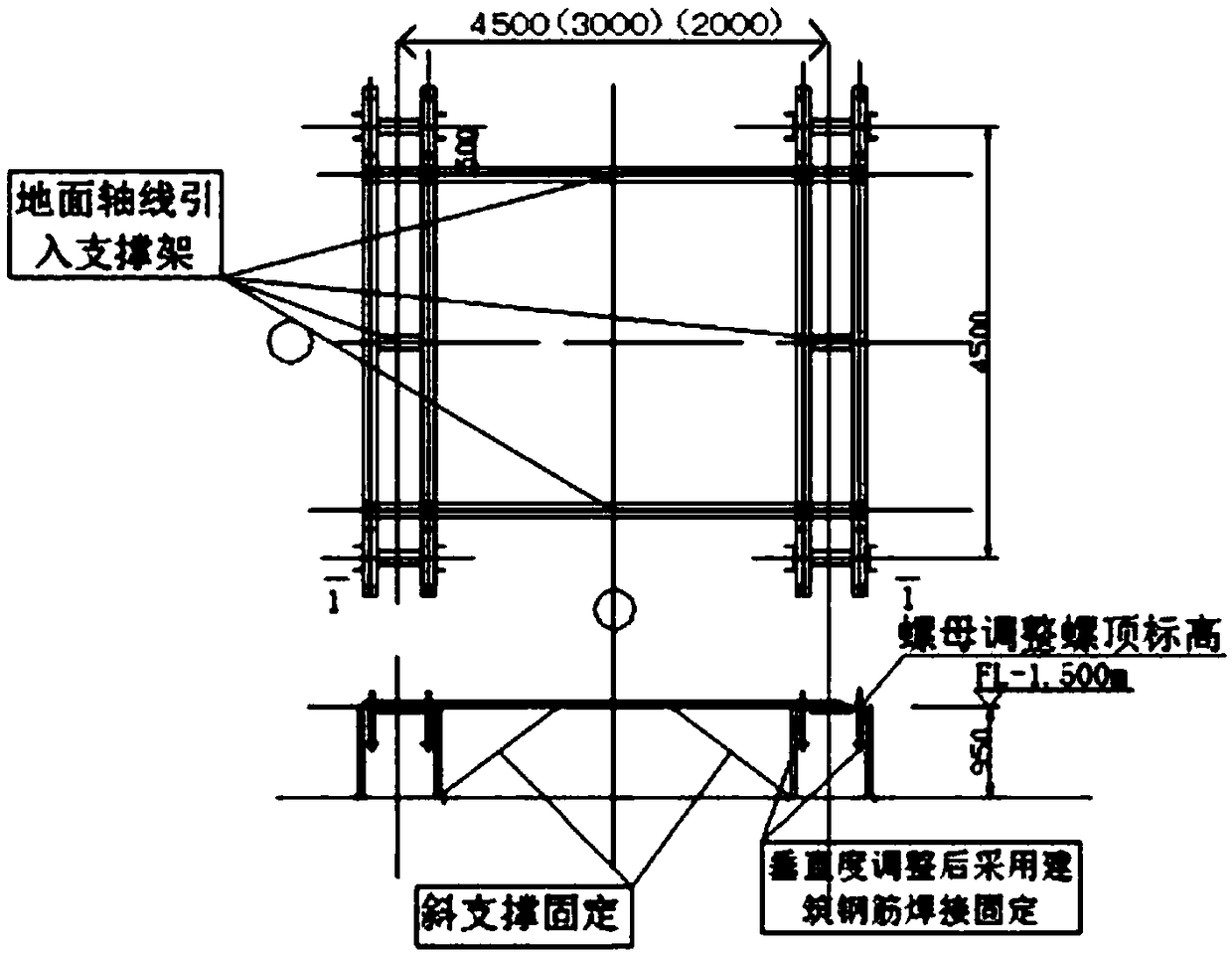

[0040] The all-weather canopy for this example adopts the super large industrial factory building structure. The canopy has an axial length of 142.6m, a width of 58m×2 spans, and a total construction area of 17,887㎡. The main structure of the canopy is composed of pipe truss steel columns and driving beams. The axial section of the pipe truss steel columns is 4.5m×2.5m~4.5m×4.5m, a total of 3 specifications, and the maximum weight of the steel columns is 105t. There are 56 driving beams in total, each with a length of about 10.2m and a weight of 3.5t. The roof of the canopy is composed of main and secondary purlins, grid structure and color plate ventilator. The specification of the main purlin is H350×350×12×9, the specification of the second...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com