Rotary type winding machine of bicycle motor

A technology for electric motors and bicycles, applied in the field of winding machines, can solve the problems of complex structure, low efficiency and high cost, achieve broad market prospects, overcome the effects of complex structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

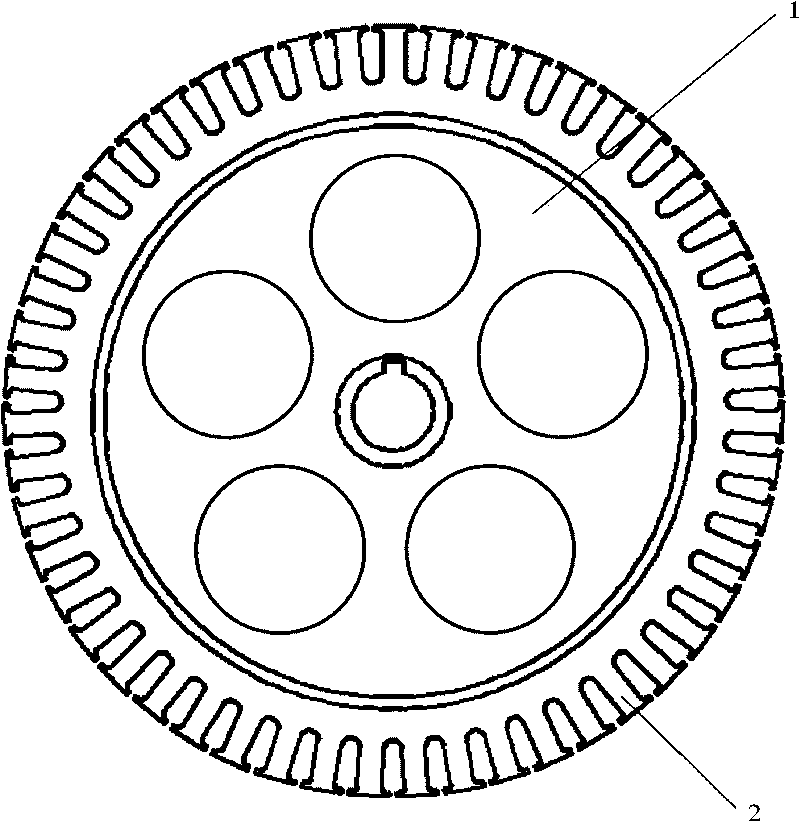

[0026] figure 1 It is the target application object of the present invention. Wherein there are bicycle motor iron core 1, support frame 2. Wherein the support frame 2 is evenly distributed on the outer periphery of the motor iron core 1, and the two form a whole, which is the support for the coil to be wound.

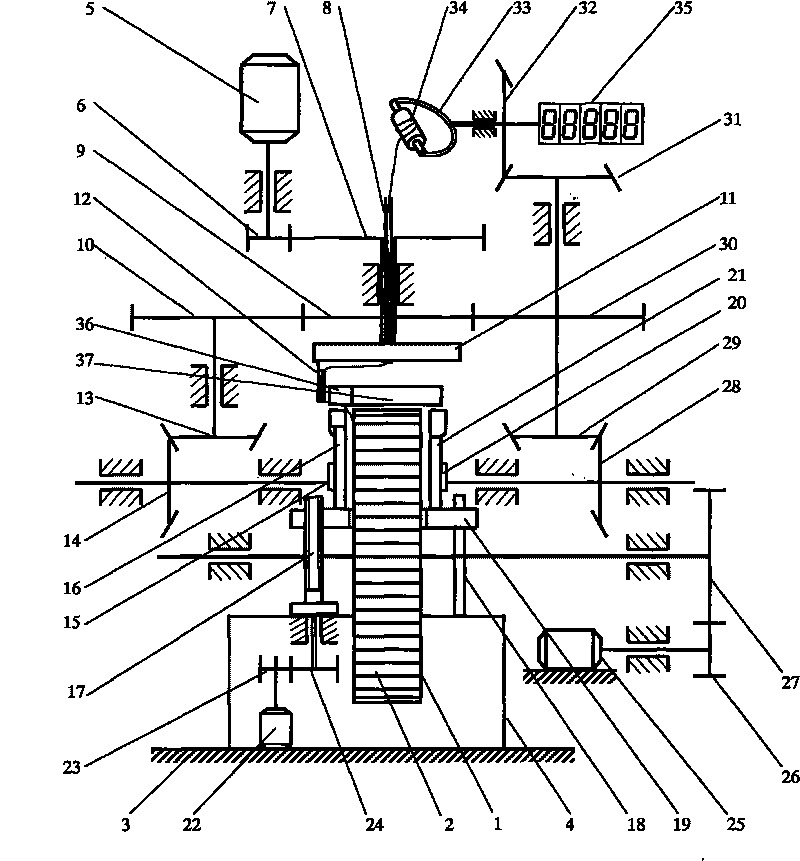

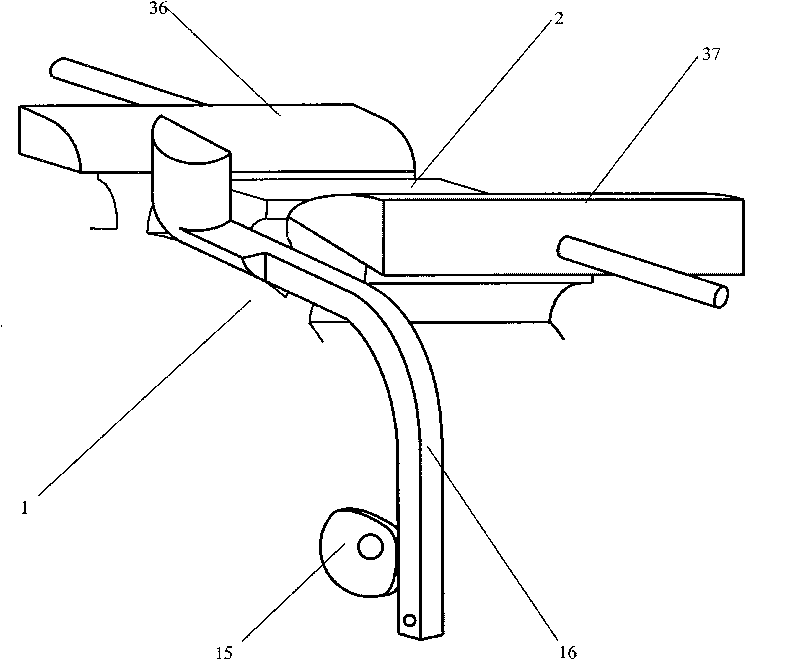

[0027] figure 2It is a schematic diagram of the mechanical principle of the present invention. Wherein there are bicycle motor iron core 1, support frame 2, support body 3, support frame 4, main motor 5, transmission wheel 6, transmission wheel 7, lead pipe 8, transmission wheel 9, transmission wheel 10, rotary disk 11, Bobbin 12, drive wheel 13, drive wheel 14, left cam 15, left crimping frame 16, left screw 17, guide rod 18, support frame 19, right cam 20, right crimping frame 21, motor 22, drive wheel 23, trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com