Precise pneumatic clamping mechanical gripper for thin plate type workpiece

A technology of manipulator claw and pneumatic clamp, used in manipulator, metal processing mechanical parts, clamping and other directions, can solve the problem of difficulty in ensuring workpiece positioning accuracy requirements, and achieve the effect of high repeated positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] Below in conjunction with accompanying drawing, the present invention will be further described through embodiment.

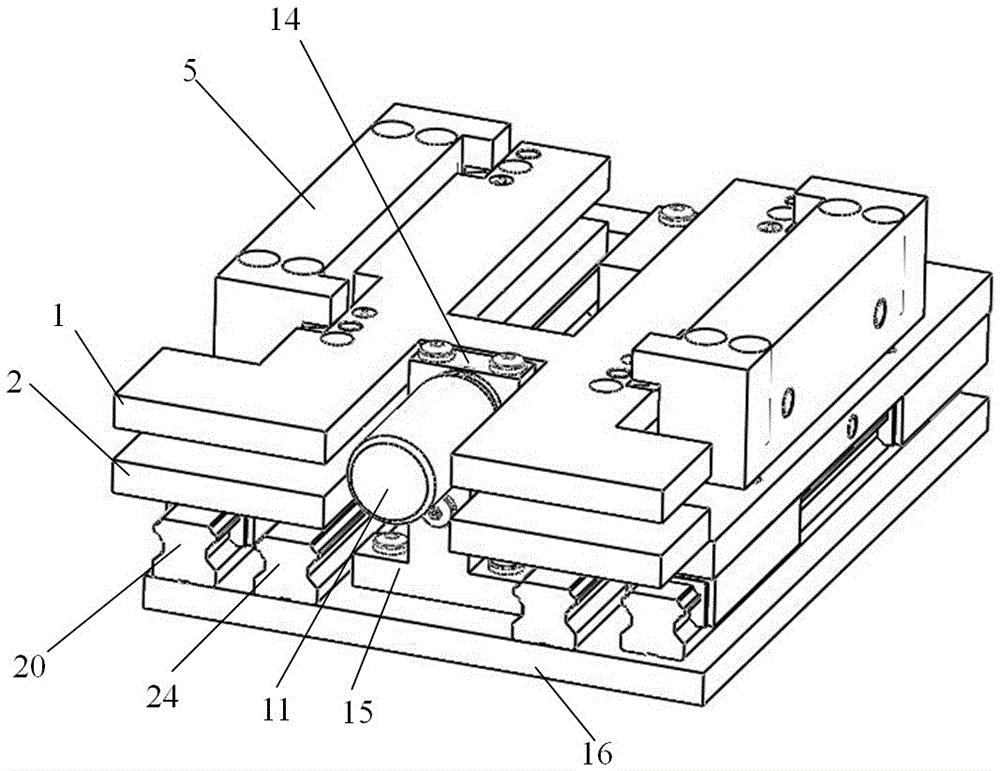

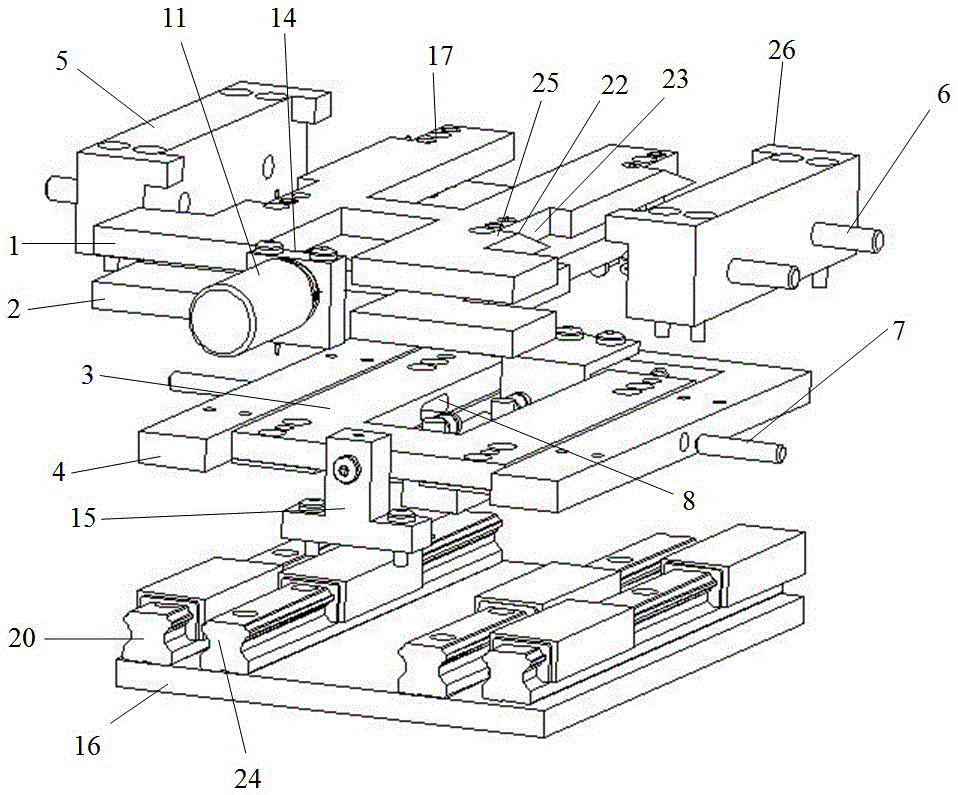

[0039] see figure 1 , a precision pneumatic clamping mechanical gripper for thin plate workpieces includes a gripping mechanism, a gripper moving mechanism and a template moving mechanism.

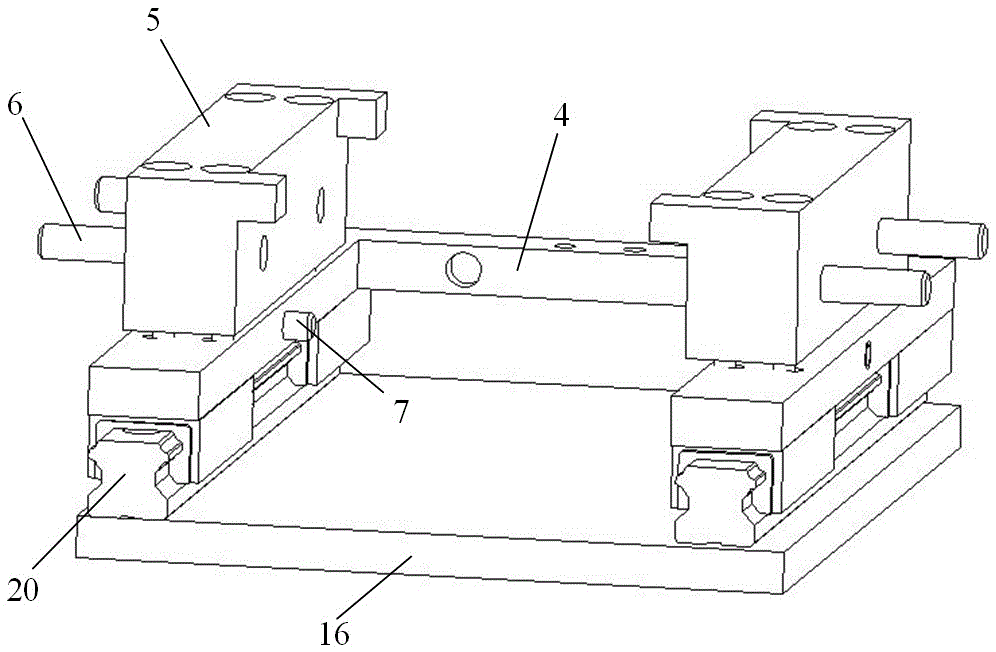

[0040] see figure 2 , The claw clamping mechanism includes a pair of plate-shaped claws corresponding up and down, a pair of formers and a positioning mechanism corresponding to left and right. The claw moving mechanism includes a sliding base plate 3 and a pair of inner guide rails 24 . The former moving mechanism includes a U-shaped frame 4, a cylinder 10 and a pair of outer guide rails 20.

[0041] A pair of plate-shaped claws includes an upper splint 1 and a lower splint 2 corresponding up and down. Both the upper splint 1 and the lower splint 2 are H-shaped plates, and one end in the length direction is a clamping end.

[0042] The bottom of the lower splin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com