Pre-compressing device

A technology of pre-compressing and pressing plates, which is applied in the direction of auxiliary devices, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., and can solve problems such as inaccurate positioning of the pressing device, welding deformation, and complicated process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, so as to make the technical solution of the present invention easier to understand and grasp.

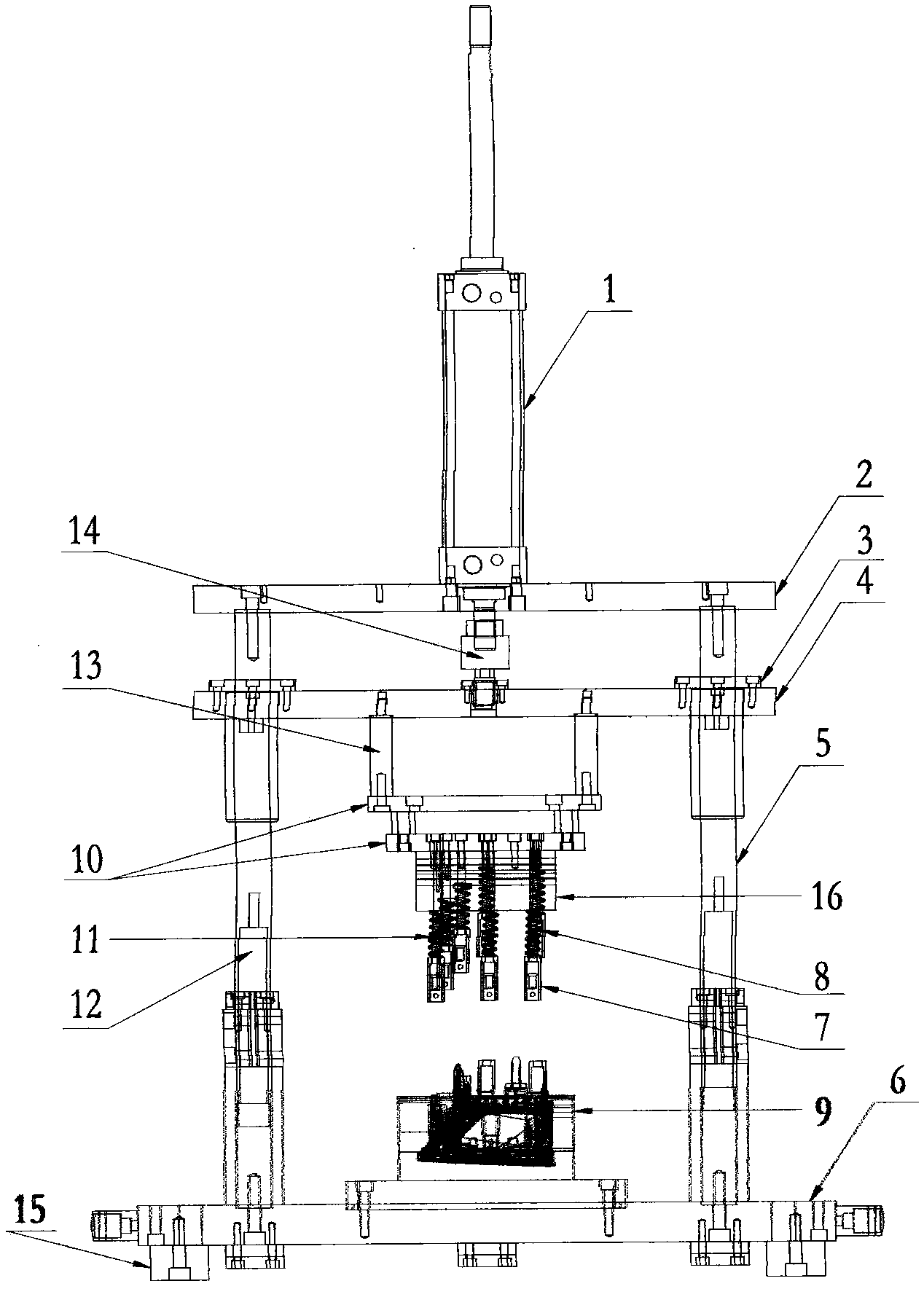

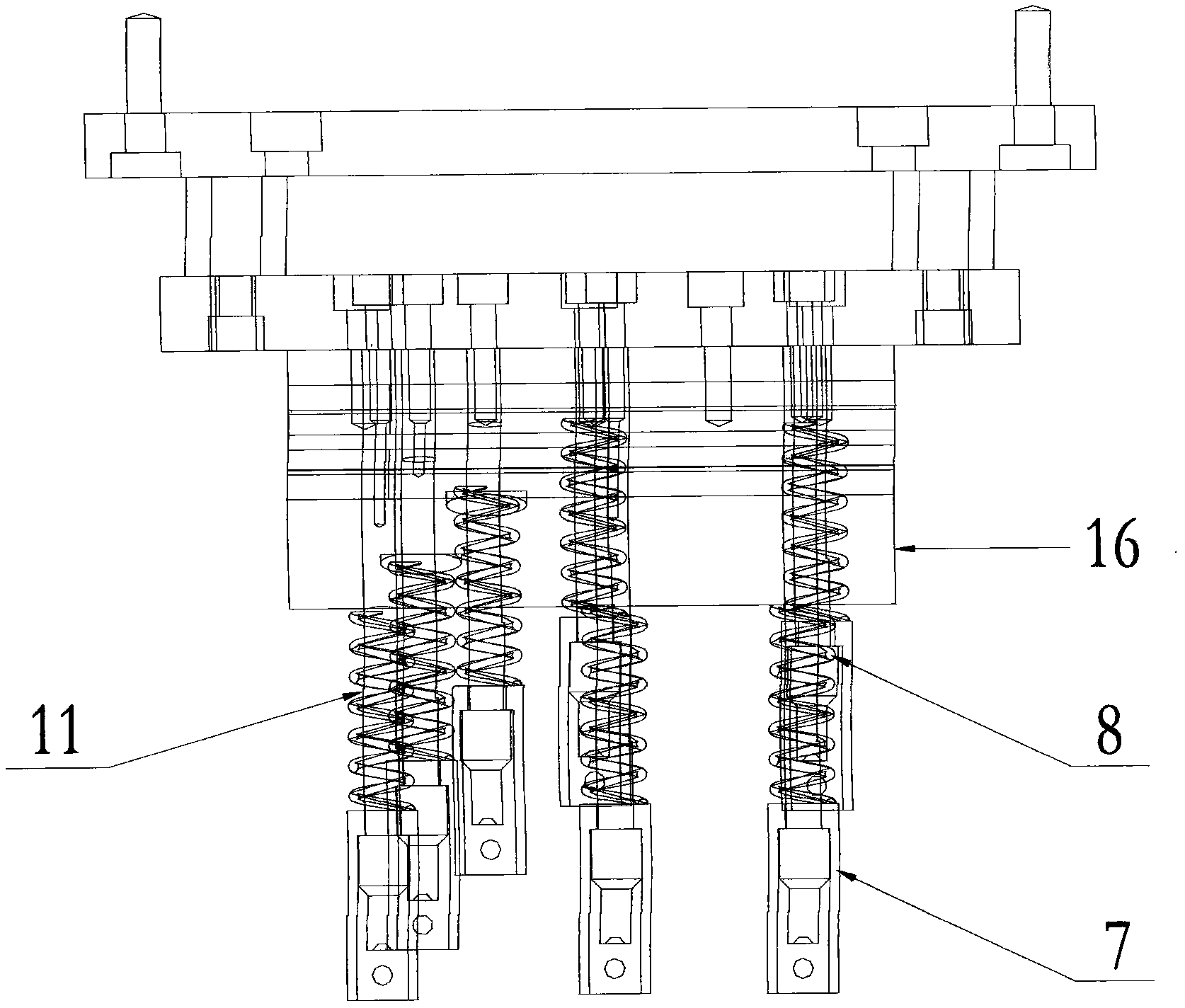

[0018] Such as figure 1 As shown, a kind of preloading device comprises base plate 6 and the product master form 9 that is fixed on this base plate 6 tops, and the bottom of base plate 6 is provided with the foot 15 that is made by rubber material, and it also includes the product and product The compression mechanism pressed by the former 9, the power mechanism that drives the movement of the compression mechanism, and the linear guide column 5 supporting the power mechanism and the compression mechanism, the linear guide column 5 and the compression mechanism are connected. Driven by the power mechanism, the mechanism moves along the linear guide column 5 and contacts the product on the bottom plate 6 .

[0019] The pressing mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com